Water-based metal priming paint for vehicles

A water-based, base color technology, applied in the field of paint and coatings, can solve the problems of water-based car paint, such as insufficient resistance, mechanical properties, hardness, toughness and weak adhesion, and achieve excellent water resistance, good MEK wiping resistance, and simple operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

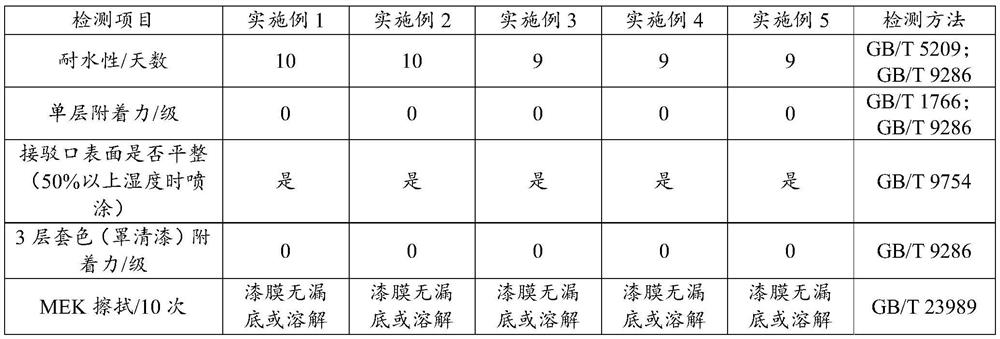

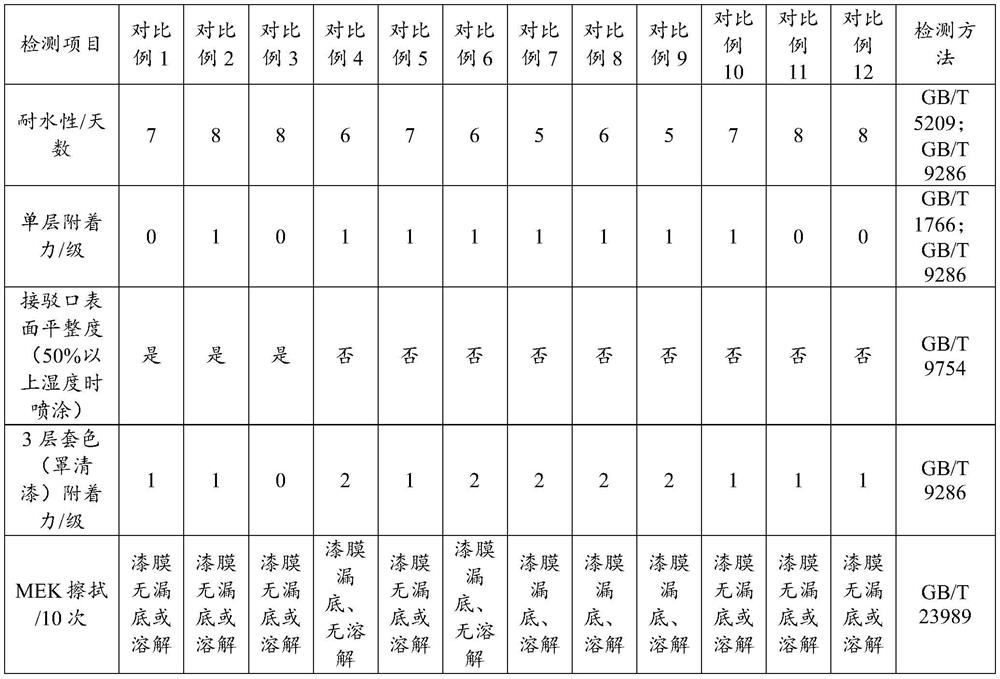

Examples

Embodiment 1

[0030] An embodiment of the water-based metal base paint for vehicles of the present invention, the water-based metal base paint for vehicles comprises A component and B component, and the mass ratio of the A component and the B component is 100 : 25; the A component includes the following components by weight: 13 parts of water-based acrylic dispersions, 21 parts of water-based acrylic polyurethane dispersions, 8 parts of water-based polyurethane dispersions, 4 parts of ethylene glycol butyl ether, 1 part of two Propylene glycol butyl ether, 0.5 parts of wetting agent, 0.2 parts of leveling agent, 5 parts of water-based orientation agent, 6 parts of water-based silver paste, 7 parts of water-based color paste, 32.6 parts of deionized water, 0.2 parts of defoamer and 1.5 parts of rheology The wetting agent is TEGO-500; the leveling agent is EFKA-3777; the water-based directional agent is BYK-8421; the water-based color paste is WLG-8000; the defoamer is a silicone defoamer; the...

Embodiment 2

[0037] An embodiment of the water-based metal base paint for vehicles of the present invention, the water-based metal base paint for vehicles comprises A component and B component, and the mass ratio of the A component and the B component is 100 : 25; the A component includes the following components by weight: 5 parts of water-based acrylic dispersions, 25 parts of water-based acrylic polyurethane dispersions, 15 parts of water-based polyurethane dispersions, 2 parts of ethylene glycol butyl ether, 4 parts of two Propylene glycol butyl ether, 1 part wetting agent, 1 part leveling agent, 2 parts water-based directional agent, 8 parts water-based silver paste, 2 parts water-based color paste, 33.5 parts deionized water, 1 part defoamer and 0.5 part rheology agent; the wetting agent is BYK-800; the leveling agent is TEGO-240; the water-based directional agent is BYK-8421; the water-based color paste is WLG-8000; the defoamer is a water-based organic polymer defoamer; The defoame...

Embodiment 3

[0040]An embodiment of the water-based metal base paint for vehicles of the present invention, the water-based metal base paint for vehicles comprises A component and B component, and the mass ratio of the A component and the B component is 100 : 25; the A component includes the following components by weight: 20 parts of water-based acrylic dispersions, 10 parts of water-based acrylic polyurethane dispersions, 5 parts of water-based polyurethane dispersions, 5 parts of ethylene glycol butyl ether, 3 parts of di Propylene glycol butyl ether, 0.1 parts of wetting agent, 0.5 parts of leveling agent, 7 parts of water-based directional agent, 2 parts of water-based silver paste, 6 parts of water-based color paste, 40 parts of deionized water, 0.2 parts of defoamer and 1.2 parts of rheology agent; the wetting agent is BYK-800; the leveling agent is EFKA-3777; the water-based directional agent is BYK-8421; the water-based colorant is WLG-8000; the defoamer is a silicone defoamer; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com