Antibacterial, antiviral, anti-formaldehyde and stain-resistant interior wall full batch powder and preparation method thereof

An anti-virus and anti-formaldehyde technology, applied in anti-fouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of single function of wall coatings, volatile harmful substances, etc., and achieve excellent physical properties , Improve anti-fouling performance, good waterproof and anti-mold anti-virus effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The anti-formaldehyde anti-fouling high-hardness multi-functional water-based coating provided in this embodiment comprises A component and B component, and the specific formula steps are as follows:

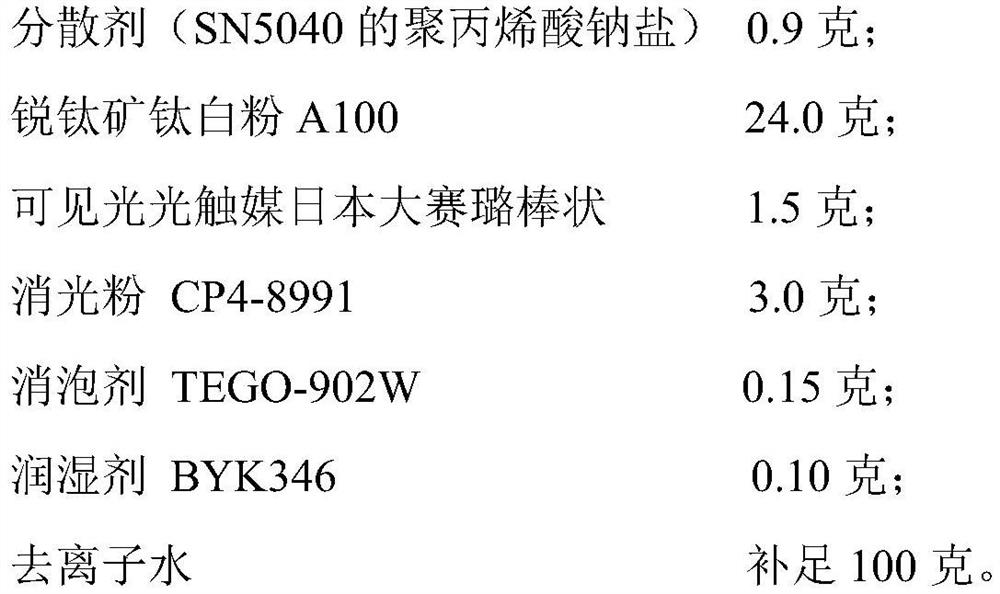

[0028] 1) Preparation of water-based functional titanium dioxide slurry (pre-preparation)

[0029] Add in order according to the mass parts under the stirring condition of the speed of the disperser at 300-500rpm:

[0030]

[0031] Then adjust the speed of the disperser to 2000rpm-3000rpm and disperse at a high speed for 30min-60min. After measuring the fineness ≤ 40μm (solid content reaches 90wt%), add the remaining water to obtain the product;

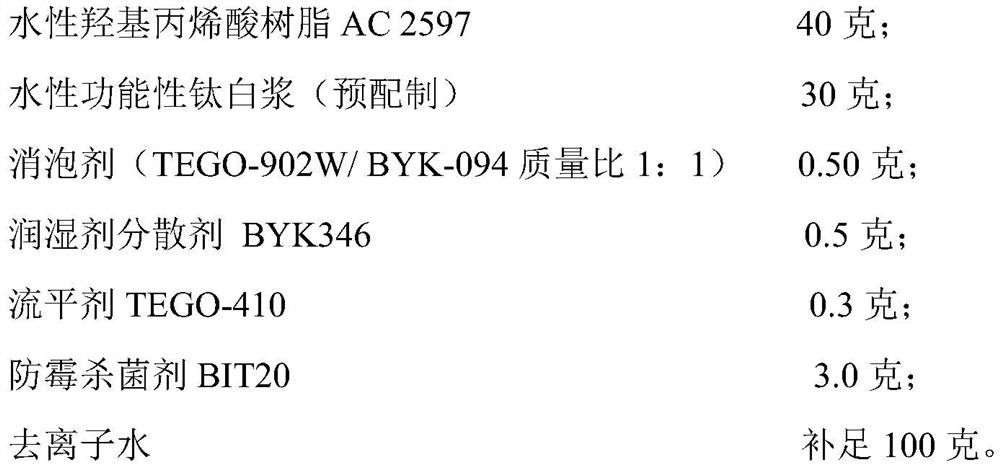

[0032] 2) Preparation of component A

[0033] Add in order according to the mass parts under the stirring condition of the speed of the disperser at 300-500rpm:

[0034]

[0035] Slowly add the thickener to adjust the viscosity, and continue to stir for 5 minutes; measure the viscosity to 35-55ku, the density to 1.1-1.3k...

Embodiment 2

[0048]The anti-formaldehyde anti-fouling high-hardness multi-functional water-based coating provided in this embodiment comprises A component and B component, and the specific formula steps are as follows:

[0049] 1) Preparation of water-based functional titanium dioxide slurry (pre-preparation)

[0050] Add in order according to the mass parts under the stirring condition of the speed of the disperser at 300-500rpm:

[0051]

[0052] Then adjust the speed of the disperser to 2000rpm-3000rpm and disperse at a high speed for 30min-60min. After measuring the fineness ≤ 40μm (solid content reaches 90wt%), add the remaining water to obtain the product;

[0053] 2) Preparation of component A

[0054] Add in order according to the mass parts under the stirring condition of the speed of the disperser at 300-500rpm:

[0055]

[0056] Slowly add the thickener to adjust the viscosity, and continue to stir for 15 minutes; measure the viscosity to 35-65ku, the density to 1.1-1.3k...

Embodiment 3

[0069] The anti-formaldehyde anti-fouling high-hardness multi-functional water-based coating provided in this embodiment comprises A component and B component, and the specific formula steps are as follows:

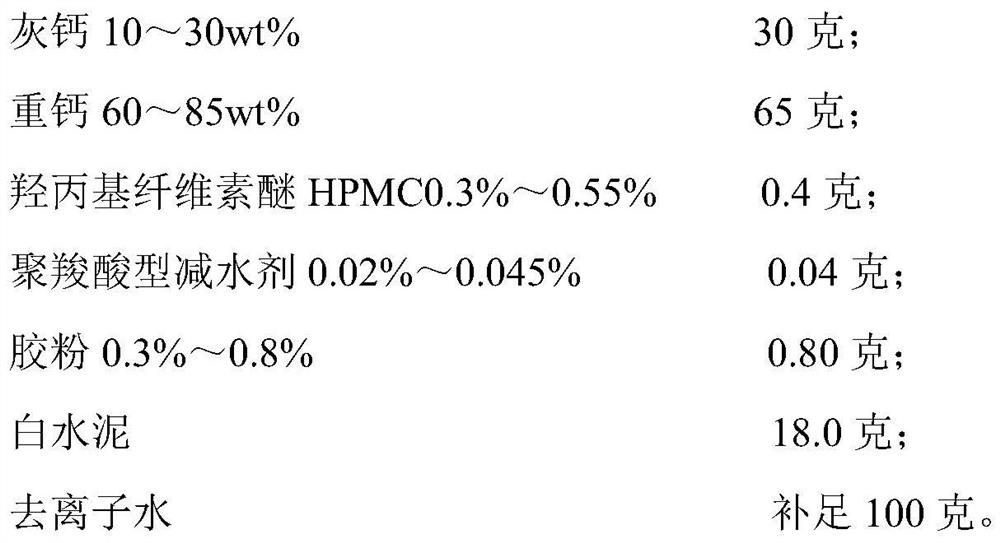

[0070] 1) Preparation of water-based functional titanium dioxide slurry (pre-preparation)

[0071] Add in order according to the mass parts under the stirring condition of the speed of the disperser at 400-500rpm:

[0072]

[0073] Then adjust the rotating speed of the disperser to 2500rpm-3000rpm and disperse at a high speed for 50min-60min. After measuring the fineness ≤ 30μm (solid content reaches 90wt%), add the remaining water to obtain the product;

[0074] 2) Preparation of component A

[0075] Add in order according to the mass parts under the stirring condition of the speed of the disperser at 300-500rpm:

[0076]

[0077] Slowly add thickener to adjust viscosity, continue to stir for 15 minutes; measure viscosity 35-65ku, density 1.1-1.3kg / L, fineness le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com