External wall flexible putty powder with light reflection capability and preparation method thereof

A technology of light reflection and putty powder, which is applied in the direction of filling slurry, etc., can solve the problems of inability to provide heat insulation functions, etc., and achieve the effect of solving heat insulation and energy-saving effects, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

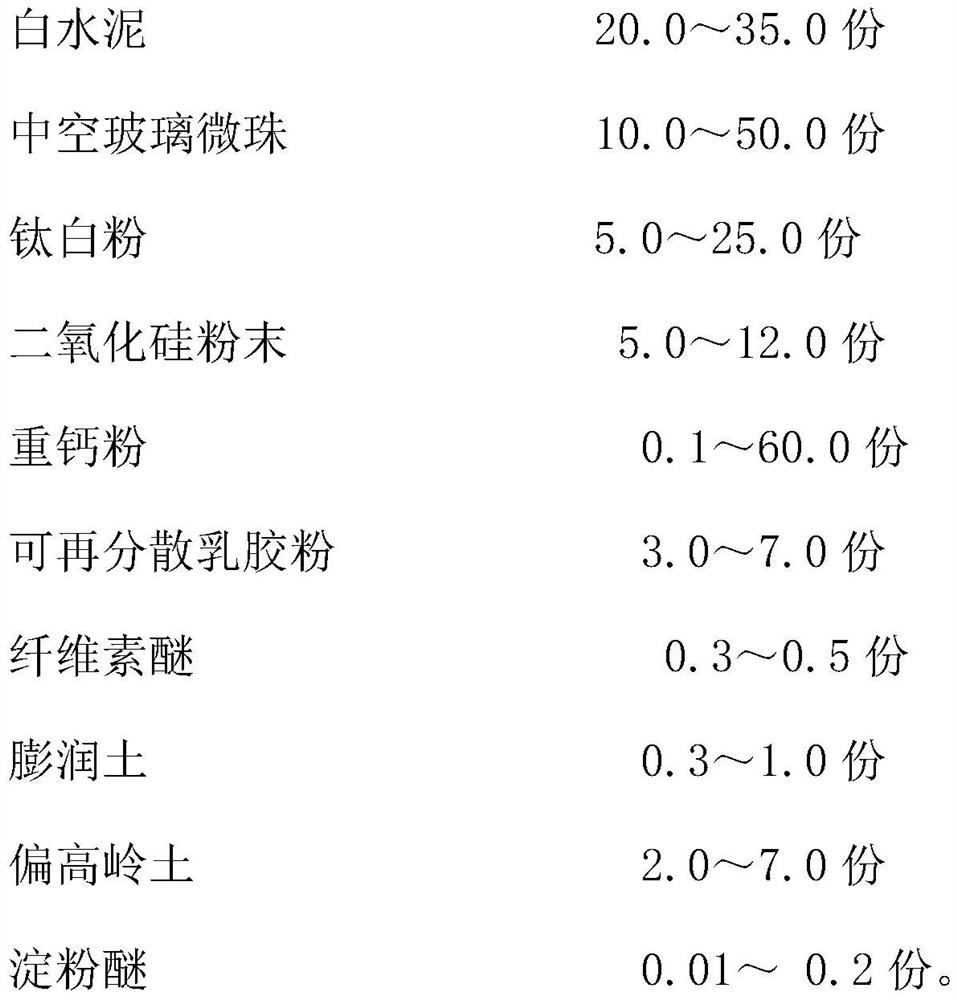

[0021] A flexible putty powder for external walls with light reflection function, which is prepared by mixing components according to the following mass and fraction ratios:

[0022]

[0023] A flexible putty powder for external walls with light reflection function is prepared by the following method: add white cement and half of the heavy calcium powder into the stirring tank, and then add titanium dioxide and modified silicon dioxide while stirring, which can be recycled Disperse latex powder, cellulose ether, bentonite, metakaolin and starch ether, then stir at a stirring rate of 2000rmp for 5 minutes, then add hollow glass microspheres and the remaining half of heavy calcium powder, and continue stirring for 3 minutes to obtain the product.

Embodiment 2

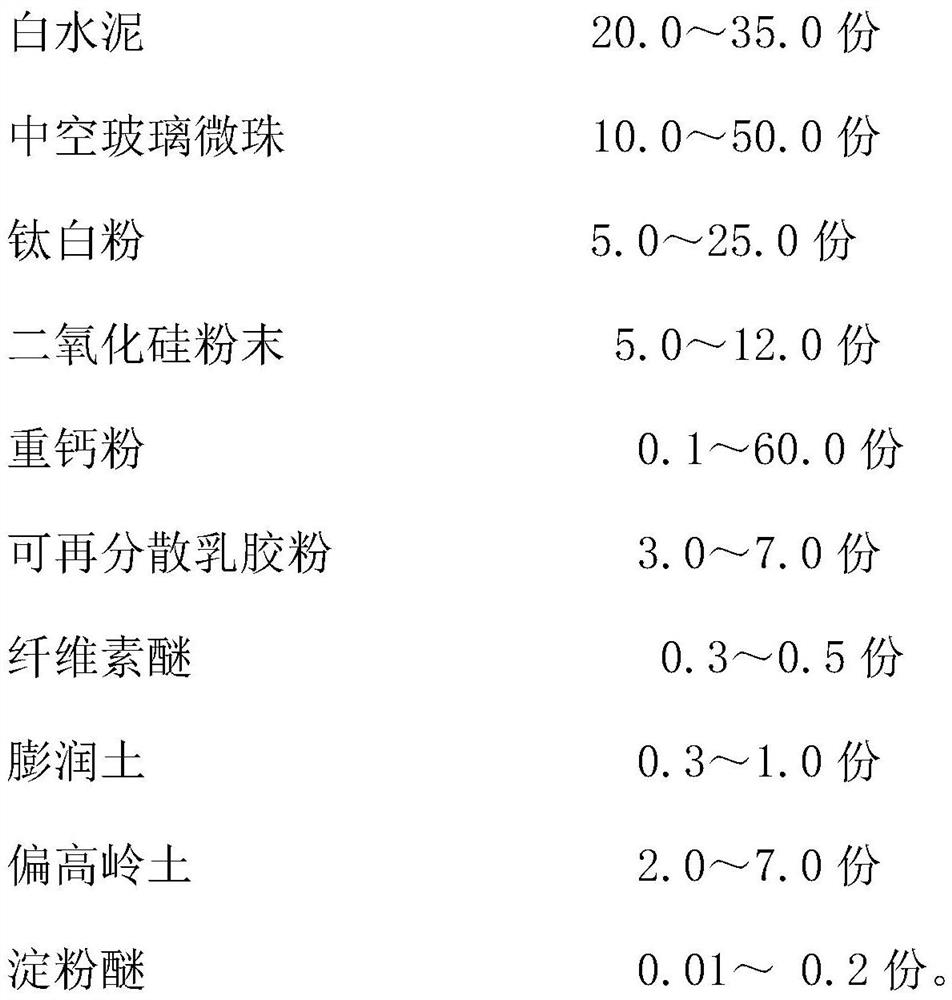

[0025] A flexible putty powder for external walls with light reflection function, which is prepared by mixing components according to the following mass and fraction ratios:

[0026]

[0027] A flexible putty powder for external walls with light reflection function is prepared by the following method: add white cement and half of the heavy calcium powder into the stirring tank, and then add titanium dioxide and modified silicon dioxide while stirring, which can be recycled Disperse latex powder, cellulose ether, bentonite, metakaolin and starch ether, then stir at a stirring rate of 3000rmp for 3 minutes, then add hollow glass microspheres and the remaining half of heavy calcium powder, and continue stirring for 3 minutes to obtain the product.

Embodiment 3

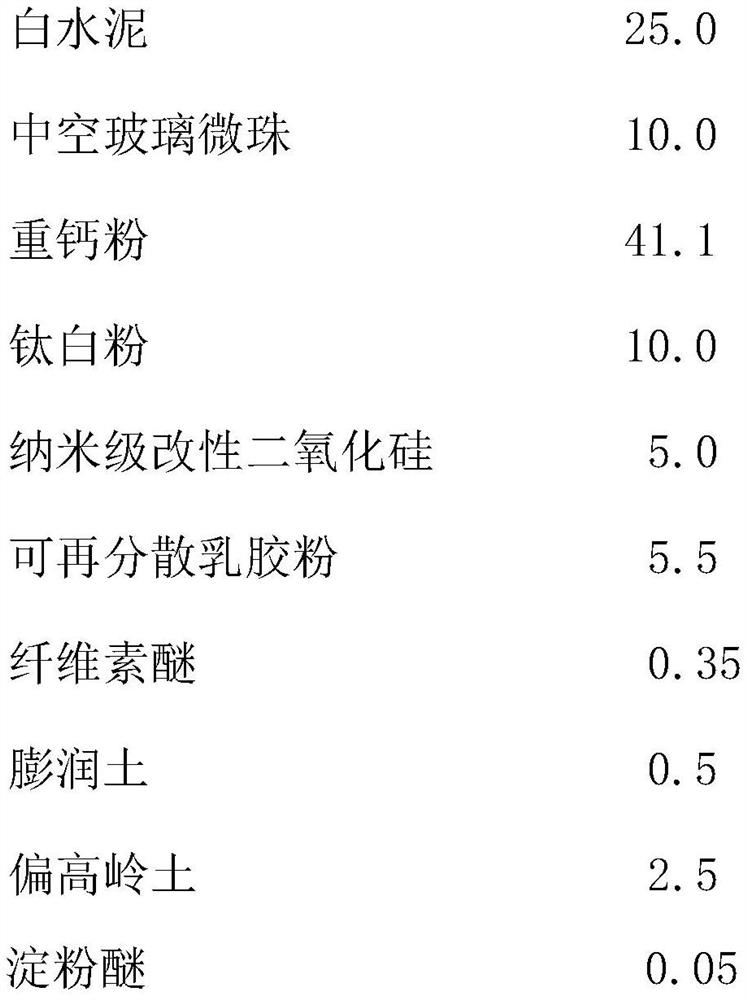

[0029] A flexible putty powder for external walls with light reflection function, which is prepared by mixing components according to the following mass and fraction ratios:

[0030]

[0031]

[0032] A flexible putty powder for external walls with light reflection function is prepared by the following method: add white cement and half of the heavy calcium powder into the stirring tank, and then add titanium dioxide and modified silicon dioxide while stirring, which can be recycled Disperse latex powder, cellulose ether, bentonite, metakaolin and starch ether, then stir for 4 minutes at a stirring rate of 2500rmp, then add hollow glass microspheres and the remaining half of heavy calcium powder, and continue stirring for 2 minutes to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com