In-service drainage pipeline trenchless plastic spraying repair material and preparation method thereof

A technology for drainage pipes and repair materials, which is applied in sewer pipe systems, waterway systems, water supply devices, etc. It can solve the problems of unsatisfactory anti-seepage effect, long construction period, and prone to hollowing, etc., to reduce long-term diversion pressure, Short construction period and the effect of preventing hollowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

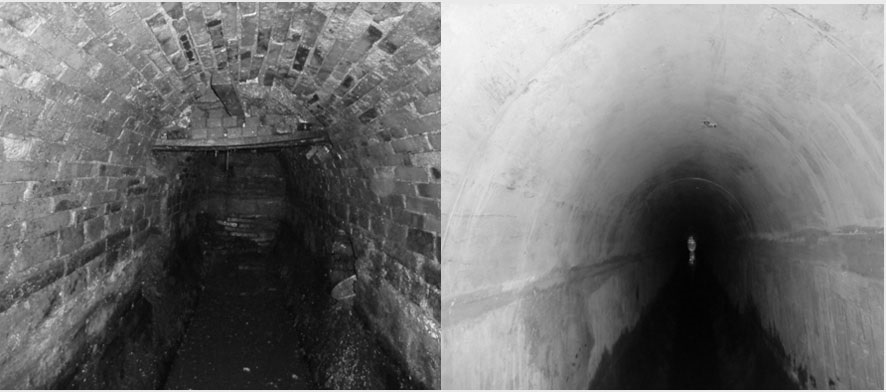

Image

Examples

Synthetic example

[0025] The water purification sludge from the waterworks in Suzhou High-tech Zone was dried at 100°C for 24 hours and then pulverized, and 800-1000 mesh was used as the water purification sludge in the following examples and comparative examples.

[0026] Soak the commercially available zeolite powder (Huaqing zeolite) in a mixed aqueous solution of 0.1mol / L hydrochloric acid and 0.2mol / L sodium sulfate at room temperature for 24 hours, then rinse with clean water, and then calcinate in air at 350°C for 2 hours, then grind Machine grinding to 200 meshes to obtain modified zeolite powder; soaking is a conventional method, and the liquid is submerged in the solid.

Embodiment

[0028] The fly ash, water purification sludge, and metakaolin are conventionally mixed and ball-milled for 30 minutes, and then conventionally mixed with cement to obtain a cementitious material.

[0029] Mix cementitious material, quartz sand, modified zeolite powder, latex powder, polyvinyl alcohol, fiber material, water retaining agent, retarder, epoxy resin, water (half of the total amount) to obtain component A, and wet Mixing agent, curing agent, and water (remaining amount) to obtain component B; mixing component A and component B to obtain non-excavation spray plastic repair materials for in-service drainage pipes; mixing is a conventional method.

[0030] The present invention provides the following examples 1-6 to specifically illustrate the components of the non-excavation plastic spraying repair material for drainage pipes in service, as shown in Table 1 below.

[0031]

[0032]

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com