A kind of carbon nitride nanosheet supported indium vanadate quantum dot photocatalyst and its preparation and application

A photocatalyst and nanosheet technology, applied in the field of photocatalytic materials, can solve the problems of poor photocatalytic reduction performance, easy recombination of photogenerated carriers, and difficult recombination of carriers, and achieve high CO2 reduction performance and wide light absorption range , is conducive to the effect of charge transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

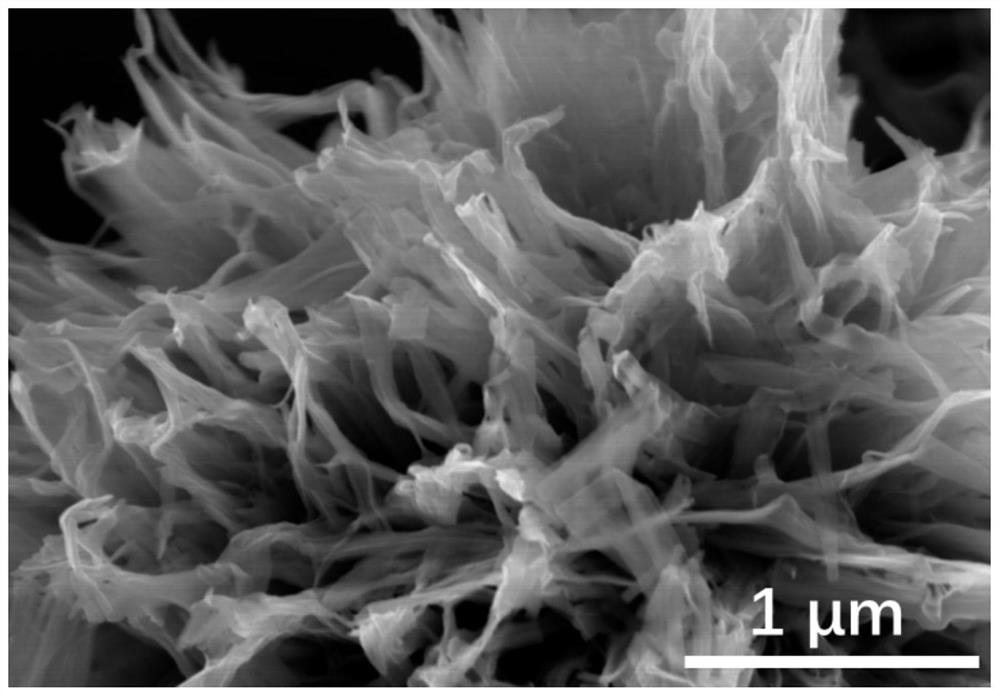

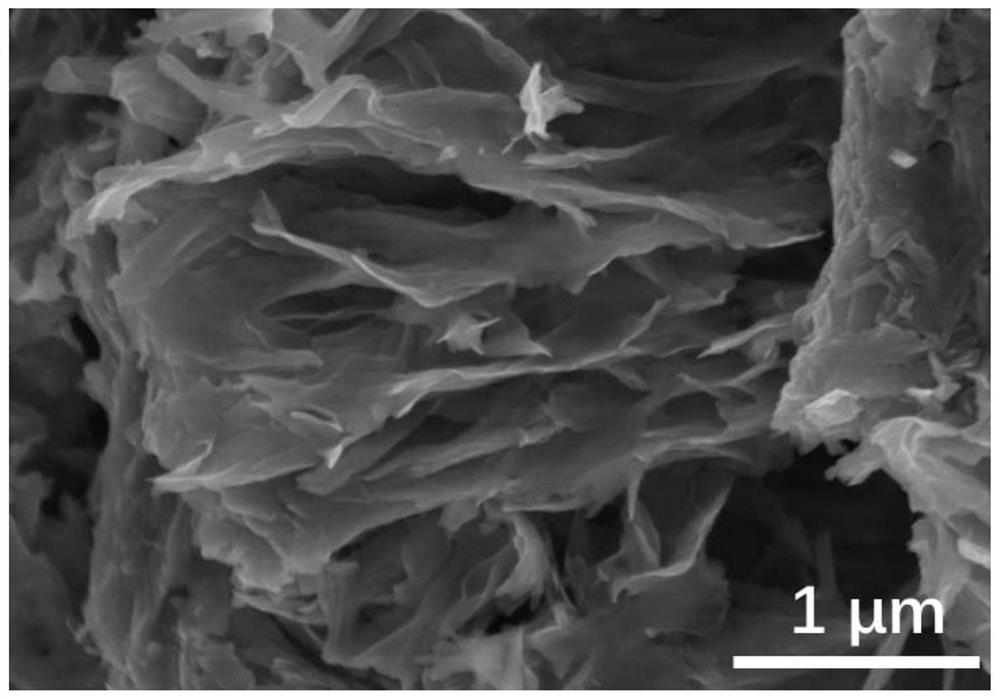

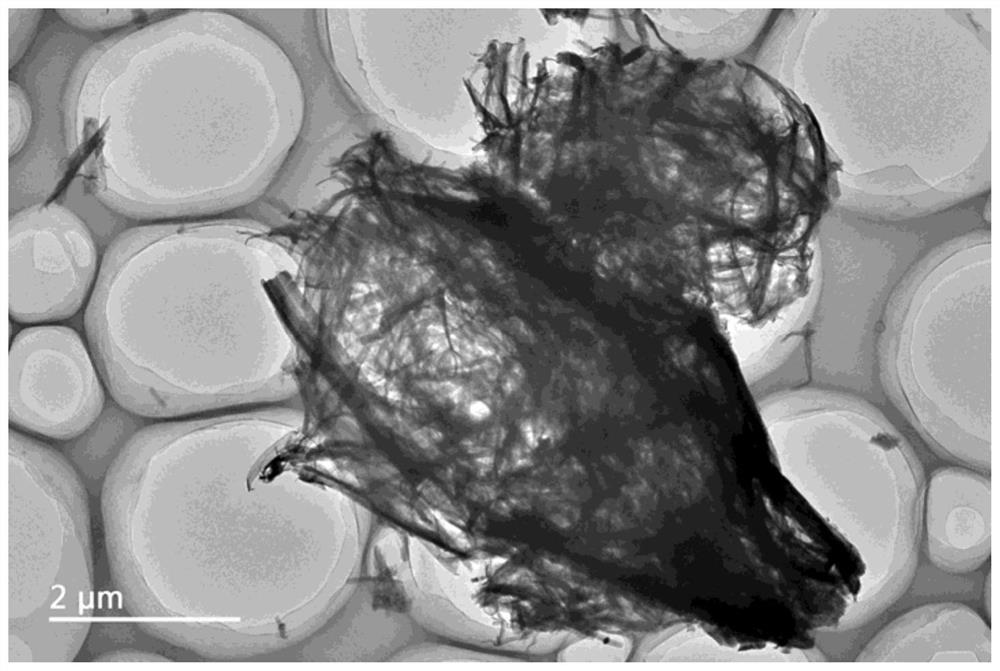

[0073] A carbon nitride nanosheet supported indium vanadate quantum dot photocatalyst mainly contains five main elements of In, V, O, C and N, and is prepared by a method comprising the following steps:

[0074] (1) Carbon nitride (hereinafter referred to as g-C3 N 4 ) preparation

[0075] Take 3g of melamine and put it in a tube furnace, heat it up to 520°C for calcination, the gas atmosphere is air, the heating rate is 5°C / min, and the temperature is kept for 4h to obtain g-C 3 N 4 ;

[0076] (2) Indium vanadate (hereinafter referred to as InVO 4 ) preparation of precursors

[0077] Dissolve 1 mmol of indium trichloride tetrahydrate in 10 mL of deionized water, and 1 mmol of sodium orthovanadate in 20 mL of deionized water to obtain an aqueous solution of 0.1 mmol / ml indium chloride and 0.05 mmol / ml of sodium orthovanadate, respectively. aqueous solution;

[0078] Then control the dropping rate to be 0.5ml / min and drop the aqueous solution of 0.1mmol / ml indium chloride...

Embodiment 2

[0106] A carbon nitride nanosheet supported indium vanadate quantum dot photocatalyst mainly contains five main elements of In, V, O, C and N, and is prepared by a method comprising the following steps:

[0107] (1) Carbon nitride (hereinafter referred to as g-C 3 N 4 ) preparation

[0108] Take 3g of melamine and put it in a tube furnace, heat it up to 520°C for calcination, the gas atmosphere is air, the heating rate is 5°C / min, and the temperature is kept for 4h to obtain g-C 3 N 4 ;

[0109] (2) Indium vanadate (hereinafter referred to as InVO 4 ) preparation of precursors

[0110] Dissolve 1 mmol of indium trichloride tetrahydrate in 10 mL of deionized water, and 1 mmol of sodium orthovanadate in 20 mL of deionized water to obtain an aqueous solution of 0.1 mmol / ml indium chloride and 0.05 mmol / ml of sodium orthovanadate, respectively. aqueous solution;

[0111] Then control the dropping rate to be 0.5ml / min and drop the aqueous solution of 0.1mmol / ml indium chlori...

Embodiment 3

[0123] A carbon nitride nanosheet supported indium vanadate quantum dot photocatalyst mainly contains five main elements of In, V, O, C and N, and is prepared by a method comprising the following steps:

[0124] (1) Carbon nitride (hereinafter referred to as g-C 3 N 4 ) preparation

[0125] Take 3g of melamine and put it in a tube furnace, heat it up to 520°C for calcination, the gas atmosphere is air, the heating rate is 5°C / min, and the temperature is kept for 4h to obtain g-C 3 N 4 ;

[0126] (2) Indium vanadate (hereinafter referred to as InVO 4 ) preparation of precursors

[0127] Dissolve 1 mmol of indium trichloride tetrahydrate in 10 mL of deionized water, and 1 mmol of sodium orthovanadate in 20 mL of deionized water to obtain an aqueous solution of 0.1 mmol / ml indium chloride and 0.05 mmol / ml of sodium orthovanadate, respectively. aqueous solution;

[0128] Then control the dropping rate to be 0.5ml / min and drop the aqueous solution of 0.1mmol / ml indium chlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com