A hyaluronic acid-based wound hemostatic repair product and preparation method thereof

A technology of hyaluronic acid and products, which can be used in pharmaceutical formulations, bandages, drug delivery, etc. It can solve the problems of low bonding fastness, easy falling off and displacement, etc., and achieve excellent adhesion performance, difficult displacement, and improved strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

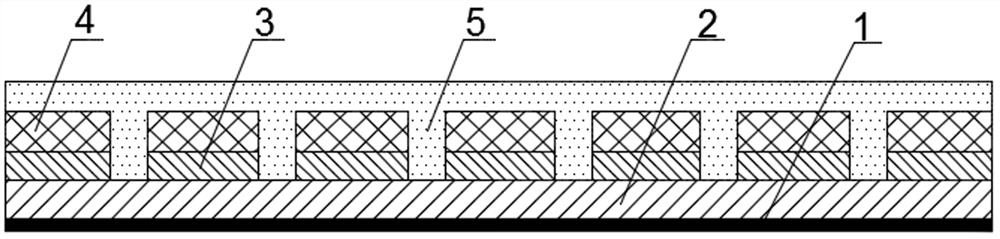

Image

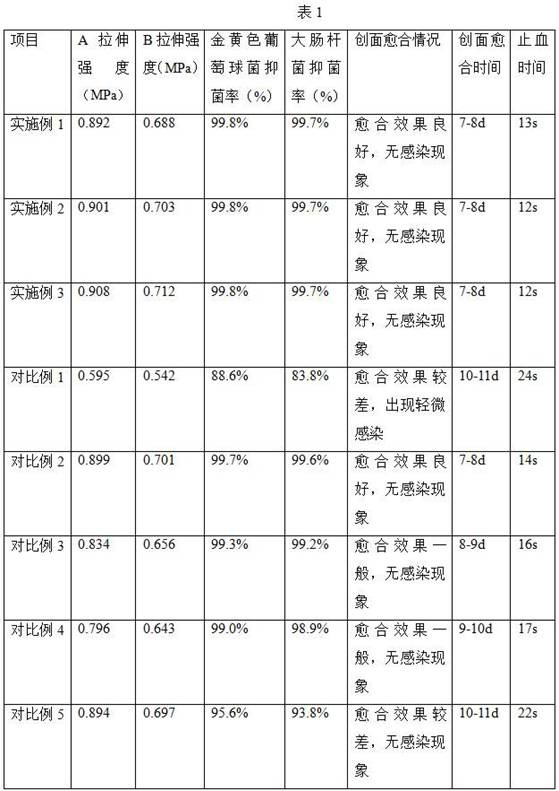

Examples

Embodiment 1

[0043] Step 1: Prepare materials;

[0044] Step 2: take the substrate, soak it in ethanol for 20 minutes, ultrasonically clean it, then clean it with deionized water, and dry it; take Tris-HCl buffer and dopamine to prepare a dopamine buffer solution, and place the dried substrate in the dopamine buffer solution In the middle, the reaction was carried out in a constant temperature water bath at 25°C for 24 hours, washed with deionized water, and dried to obtain a pretreated substrate with a polydopamine layer on the upper surface; the thickness of the polydopamine layer was 40 nm, and the substrate was non-woven fabric;

[0045] Step 3: Place the pretreated substrate in a magnetron sputtering vacuum chamber, vacuumize and perform magnetron sputtering coating under the protection of argon gas, first coat a titanium layer on the surface of the polydopamine layer of the pretreated substrate, and then Coating a layer of silver on the surface of the titanium layer to obtain a modif...

Embodiment 2

[0051] Step 1: Prepare materials;

[0052] Step 2: take the substrate, soak it in ethanol for 25 minutes, ultrasonically clean it, then clean it with deionized water, and dry it; take Tris-HCl buffer and dopamine to prepare a dopamine buffer solution, and place the dried substrate in the dopamine buffer solution In the middle, the reaction was performed in a constant temperature water bath at 27°C for 26 hours, washed with deionized water, and dried to obtain a pretreated substrate with a polydopamine layer on the upper surface; the substrate was a non-woven fabric, and the thickness of the polydopamine layer was 43 nm;

[0053] Step 3: Place the pretreated substrate in a magnetron sputtering vacuum chamber, vacuumize and perform magnetron sputtering coating under the protection of argon gas, first coat a titanium layer on the surface of the polydopamine layer of the pretreated substrate, and then Coating a layer of silver on the surface of the titanium layer to obtain a modif...

Embodiment 3

[0059] Step 1: Prepare materials;

[0060] Step 2: take the substrate, soak it in ethanol for 30 minutes, ultrasonically clean it, then clean it with deionized water, and dry it; take Tris-HCl buffer and dopamine to prepare a dopamine buffer solution, and place the dried substrate in the dopamine buffer solution In the middle, the reaction was performed in a constant temperature water bath at 28°C for 28 hours, washed with deionized water, and dried to obtain a pretreated substrate with a polydopamine layer on the upper surface; the substrate was a non-woven fabric, and the thickness of the polydopamine layer was 45 nm;

[0061] Step 3: Place the pretreated substrate in a magnetron sputtering vacuum chamber, vacuumize and perform magnetron sputtering coating under the protection of argon gas, first coat a titanium layer on the surface of the polydopamine layer of the pretreated substrate, and then Coating a layer of silver on the surface of the titanium layer to obtain a modif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com