Meat mincer for processing quick-frozen food and meat mincing method for producing wontons with swallow wrappers

A technology of quick-frozen food and meat grinder, which is applied in the direction of processing meat, meat processing equipment, chemical instruments and methods, etc., can solve the problems of inability to clean the inner wall, incomplete peeling, affecting the normality of the ground meat, etc., so as to improve the cleaning performance. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

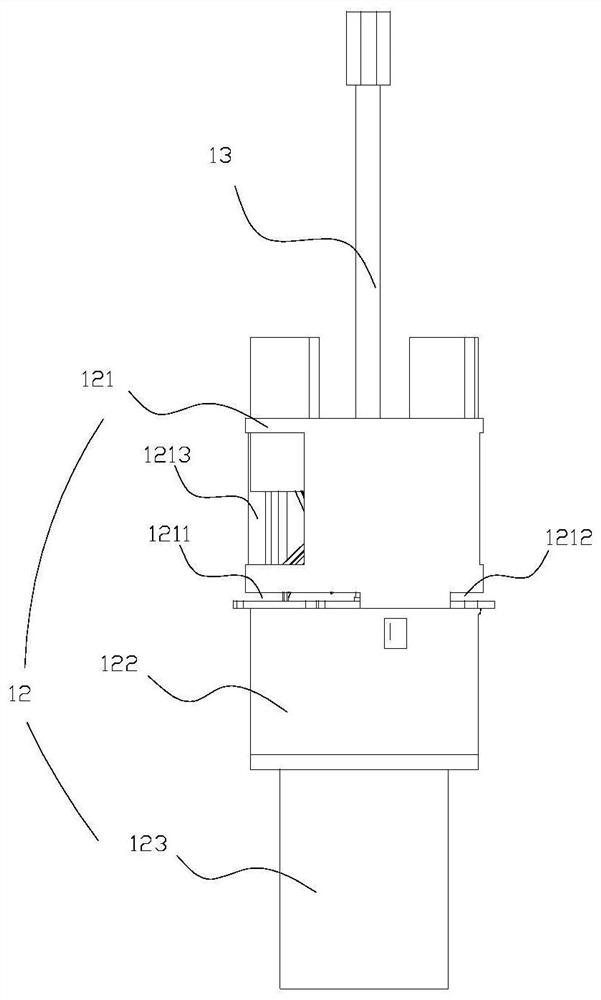

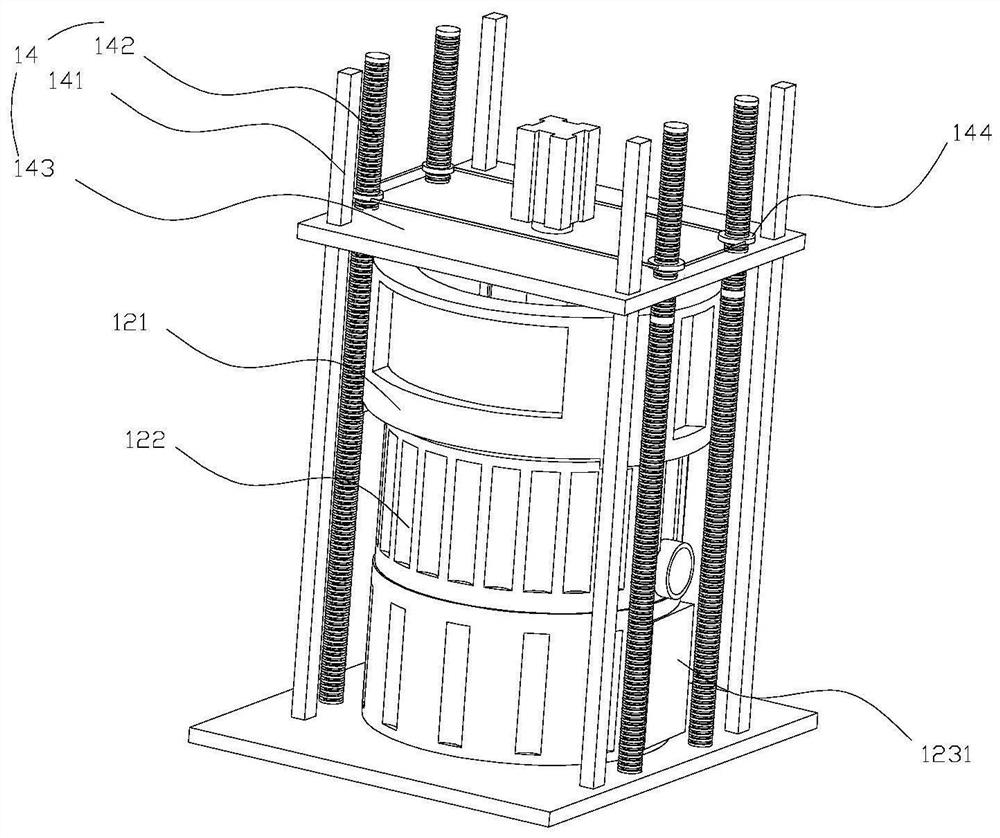

[0057] Such as Figure 1-3 As shown, this embodiment discloses a meat grinder for quick-frozen food processing, including a housing 12 , a meat grinder 13 , a height adjustment device 14 , and a cleaning member 15 . The housing 12 sequentially includes a cleaning bin 121 , a minced meat bin 122 , and a tail bin 123 which communicate with each other from top to bottom. The housing 12 is provided with a first notch 1211, a second notch 1212, and a cleaning port 1213. The cleaning port 1213 is located above the first notch 1211 and the second notch 1212. The cleaning port 1213, the first notch 1211, and the second notch 1212 All communicate with the cleaning chamber 121.

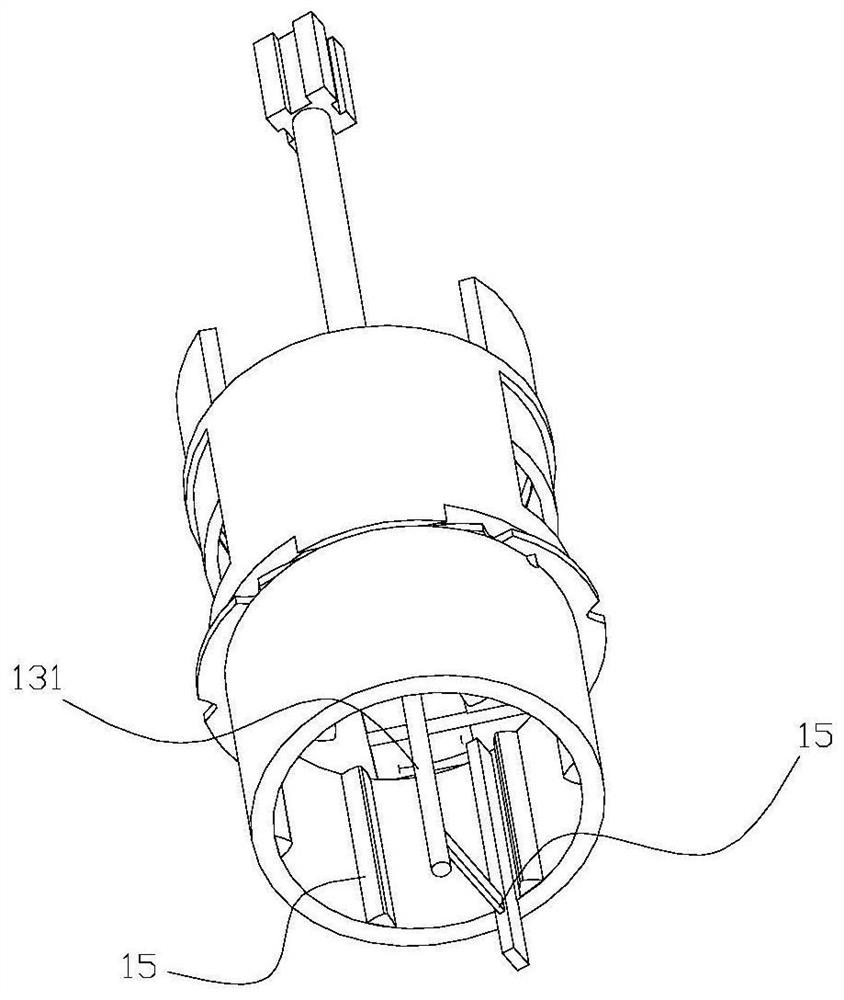

[0058] Such as Figure 3-6 As shown, the meat grinding device 13 includes a rotating shaft 131 , a blade 132 , a base 133 , a first movable disk 134 , a second movable disk 135 , and a connecting rail 136 . The middle section of the rotating shaft 131 is rotatably matched with the base 133, and the connectin...

Embodiment 2

[0066] Such as Figure 9 As shown, the difference between this embodiment and the above-mentioned embodiments is that: the inner wall of the meat grinding bin 122 is provided with stirring edges 1221 extending from top to bottom, and a plurality of stirring edges 1221 are arranged in a ring shape. Such as Figure 4-6 As shown, openings (not shown) with the same number of stirring ribs 1221 penetrating from top to bottom are opened on the edge of the overall structure. The vertical projections of the corresponding stirring edges 1221 and openings coincide.

[0067] Since the present invention is provided with a stirring edge 1221 extending from top to bottom on the inner wall of the meat grinding bin 122, and a plurality of stirring edges 1221 are distributed in a ring shape, when the meat is ground, the stirring edge 1221 is used to cooperate with the blade 132 to grind the meat. Further ensure the uniformity of ground meat. Due to the introduction of the stirring edge 1221...

Embodiment 3

[0072] The difference between this embodiment and the above-mentioned embodiment is: when the side peripheral surface of the overall structure moves upward beyond the height of the first notch 1211 and the second notch 1212 and contacts the inner peripheral wall of the cleaning chamber 121, the cleaning end of the cleaning member 15 can automatically It runs through the inner wall of the meat grinding bin 122 from top to bottom.

[0073] Such as Figure 10 As shown, further, the inner wall of the cleaning chamber 121 is provided with a third magnetic block, and the top of the first movable disk 134 and the top of the second movable disk 135 are respectively provided with a fourth magnetic block, when the first movable disk 134, the second movable disk 135 The movable disc 135 is assembled into an integral structure, and the top of the integral structure can be magnetically attracted to the inner wall of the cleaning chamber 121 to ensure that the rotation of the rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com