Carbon-based/PANI composite electrode material for supercapacitor and preparation method of carbon-based/PANI composite electrode material

A supercapacitor and composite electrode technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve problems affecting cycle stability, blocked charge transfer, unfavorable ion diffusion, etc., to improve cycle stability and rate The effect of performance, realization of stacking, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

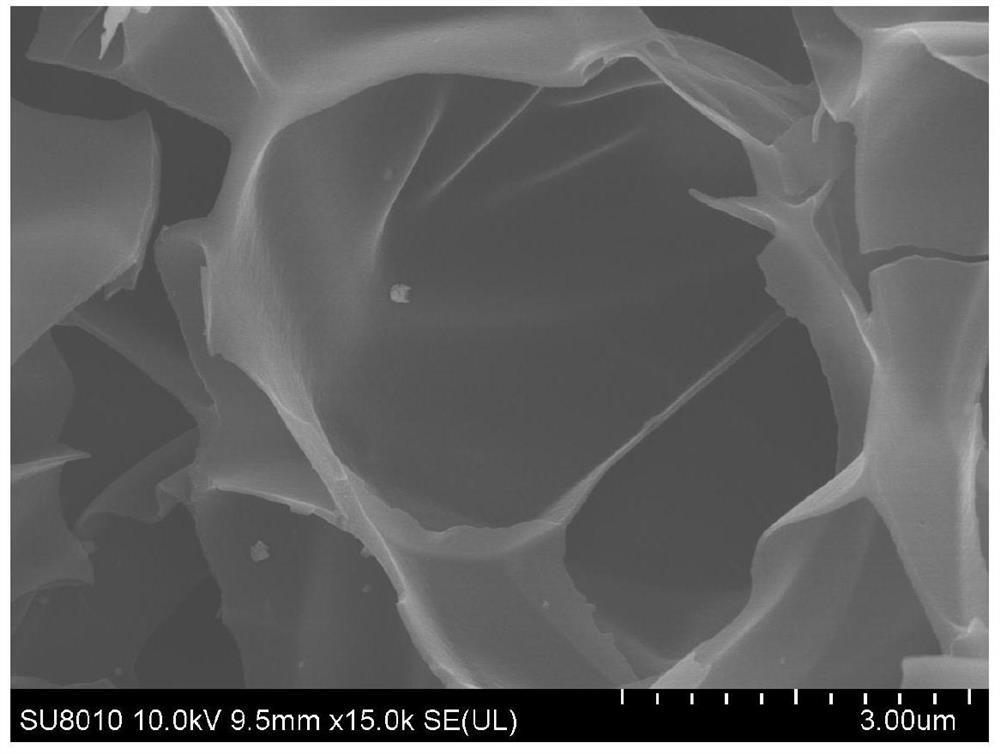

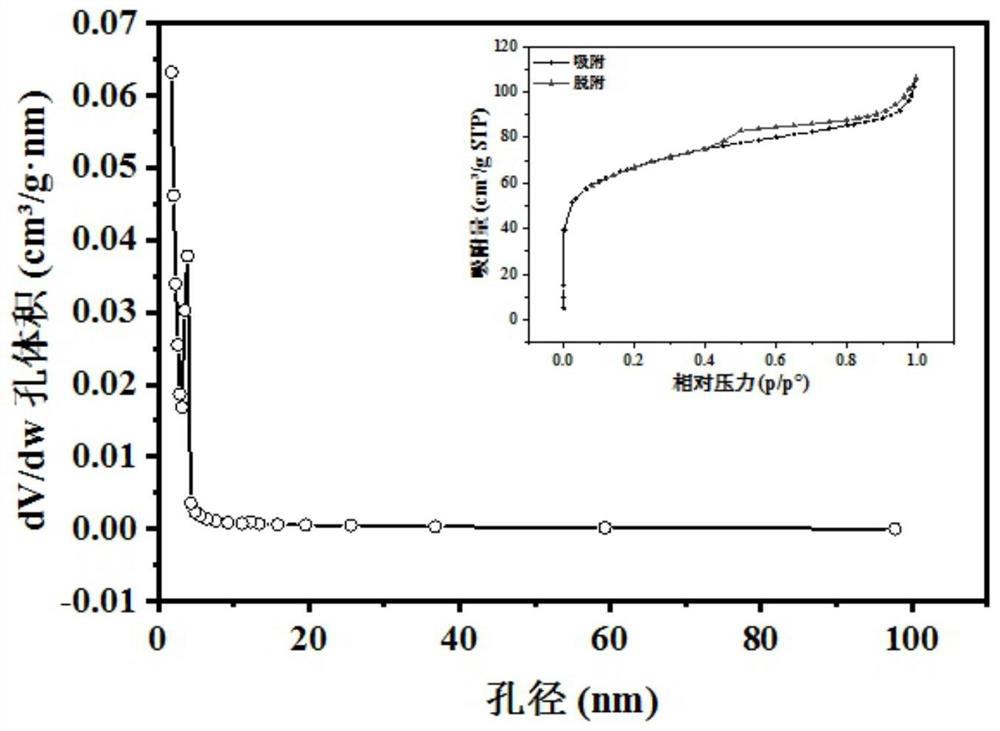

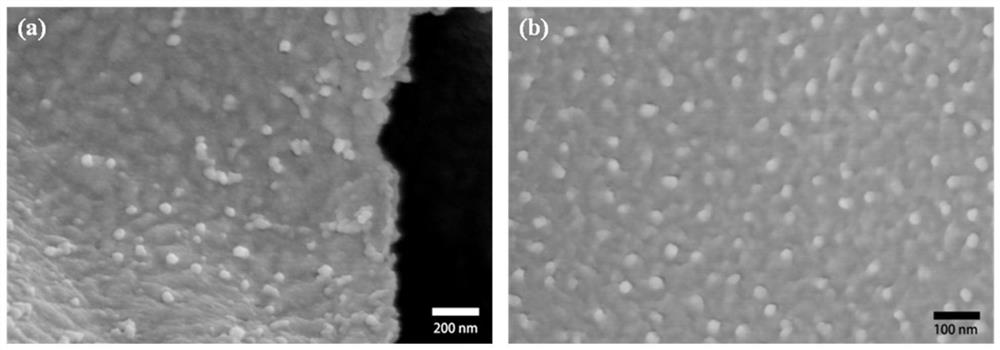

[0040] (1) Dissolve 0.571 g of ammonium persulfate (APS) in 50 mL of deionized water to obtain a clear solution; add 50 mg of 3DN-PC material to the aforementioned clear solution, and stir magnetically at room temperature for 24 h to obtain a black dispersion. Experiments show that reducing the concentration of APS will increase the particle size of polyaniline nanoparticles but reduce the amount.

[0041] (2) Suction-filter and wash the dispersion obtained above to obtain 3D N-PC with APS adsorbed.

[0042] (3) Dissolve 2733.5 μL of concentrated sulfuric acid in 50 mL of deionized water, and then divide it into two portions of 20 mL and 30 mL.

[0043] (4) Add 191.5 μL of aniline monomer to the above 20 mL of sulfuric acid solution, and dissolve it by ultrasonication for about 20 min to obtain a mixed solution containing aniline monomer, which is designated as mixed solution A, and placed in an ice bath at 0 °C Pre-cool in the machine.

[0044] (5) Transfer the product obta...

Embodiment 2

[0048] (1) 1.141 g of ammonium persulfate (APS) was dissolved in 50 mL of deionized water to obtain a clear solution; 50 mg of 3DN-PC material was added to the aforementioned clear solution, and magnetically stirred at room temperature for 24 h to obtain a black dispersion.

[0049] (2) The dispersion liquid obtained above was subjected to suction filtration and washing to obtain 3D N-PC with adsorbed APS.

[0050] (3) Dissolve 2733.5 μL of concentrated sulfuric acid in 50 mL of deionized water, and then divide it into two portions of 20 mL and 30 mL.

[0051] (4) Add 191.5 μL of aniline monomer to the above 20 mL of sulfuric acid solution, and dissolve it by ultrasonication for about 20 min to obtain a mixed solution containing aniline monomer, which is designated as mixed solution A, and placed in an ice bath at 0 °C Pre-cool in the machine.

[0052] (5) Transfer the product obtained in step (2) to a round-bottomed flask containing 30 mL of sulfuric acid solution, and perfo...

Embodiment 3

[0059] (1) 2.282 g of ammonium persulfate (APS) was dissolved in 50 mL of deionized water to obtain a clear solution; 50 mg of 3DN-PC material was added to the aforementioned clear solution, and magnetically stirred at room temperature for 24 h to obtain a black dispersion.

[0060] (2) The dispersion liquid obtained above was subjected to suction filtration and washing to obtain 3D N-PC with adsorbed APS.

[0061] (3) Dissolve 2733.5 μL of concentrated sulfuric acid in 50 mL of deionized water, and then divide it into two portions of 20 mL and 30 mL.

[0062] (4) Add 191.5 μL of aniline monomer to the above 20 mL of sulfuric acid solution, and dissolve it by ultrasonication for about 20 min to obtain a mixed solution containing aniline monomer, which is designated as mixed solution A, and placed in an ice bath at 0 °C Pre-cool in the machine.

[0063] (5) Transfer the product obtained in step (2) to a round-bottomed flask containing 30 mL of sulfuric acid solution, and perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com