Gallate red-light fluorescent material and preparation method and white-light LED light-emitting device

A technology for red fluorescent and light-emitting devices, applied in the fields of luminescent materials, chemical instruments and methods, climate sustainability, etc., can solve the problems of low color rendering index, high correlated color temperature, insufficient red light component of WLEDs, etc. Effective and economical, easy to operate, good color temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The chemical composition formula of the red fluorescent material of this embodiment is Sr 2 sc 0.5 Ga 1.5 o 5 :xEu 2+ , where x=0.02. According to the stoichiometric ratio of each element in the chemical formula, accurately weigh the powder raw material SrCO 3 , Sc 2 o 3 , Ga 2 o 3 , Eu 2 o 3 . And take the mass ratio of relative total raw material 10%H 3 BO 3 , placed in an agate mortar and ground until the raw materials are fully mixed and evenly transferred to an alumina crucible, placed in a high-frequency induction heater with a reducing atmosphere, rapidly sintered at 1450°C for 5 minutes, cooled naturally, taken out, and ground again A single-phase red fluorescent material was obtained.

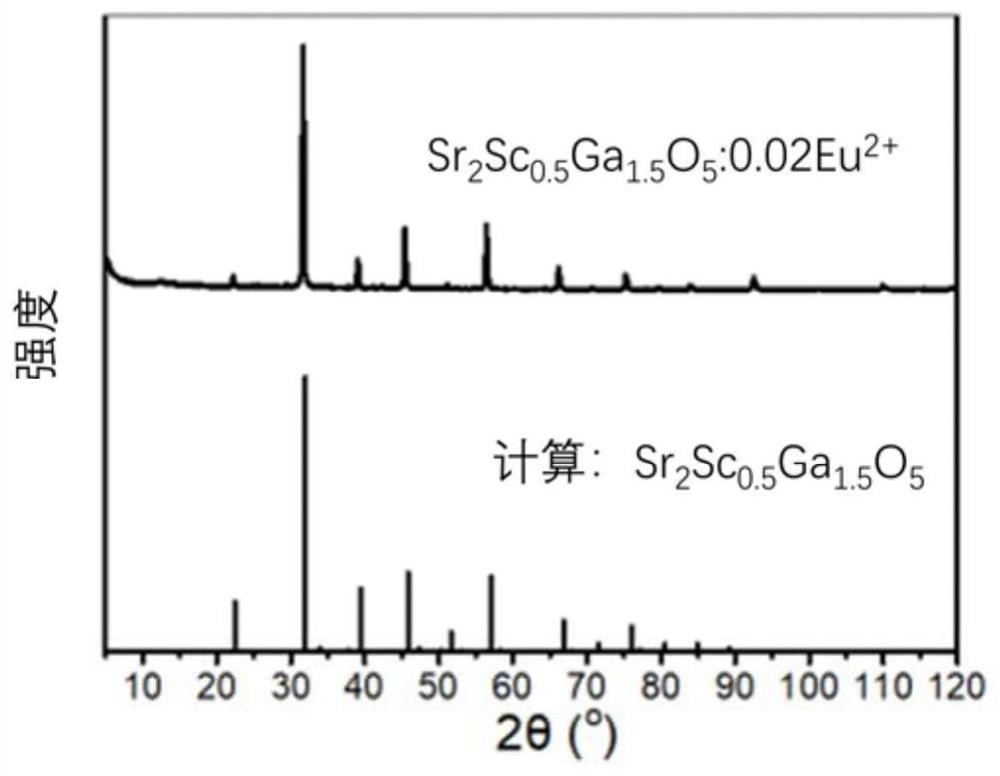

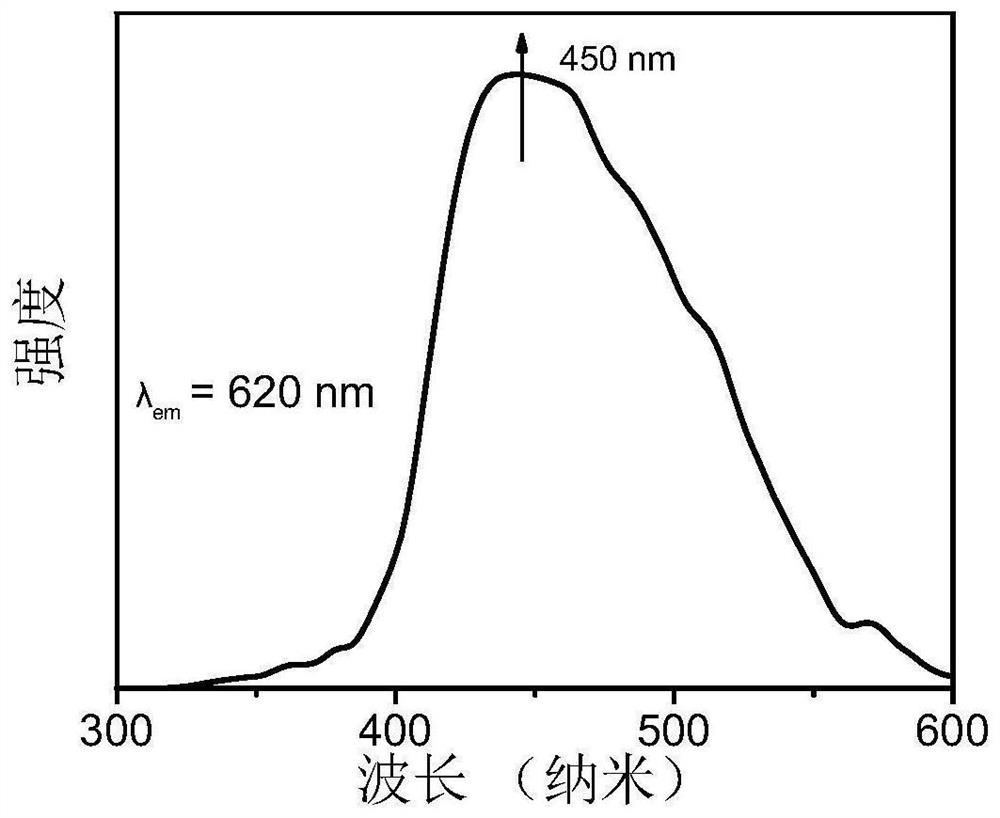

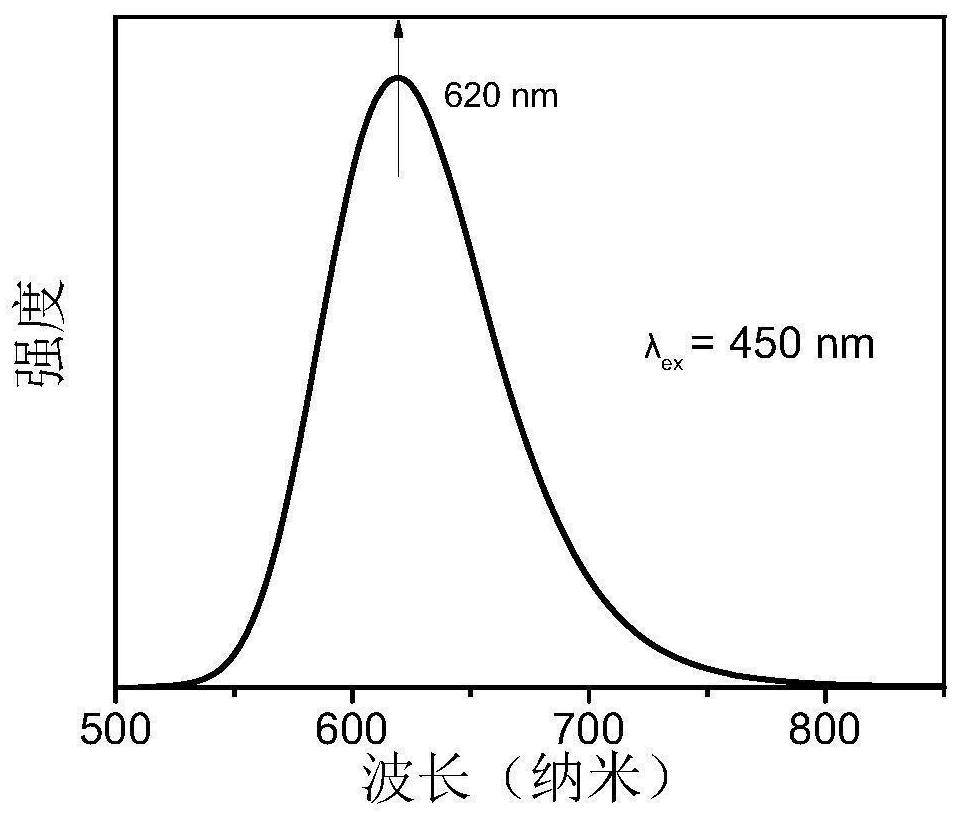

[0041] Such as figure 1 , the XRD pattern results prove that no impurity phase is generated, indicating that the phase is pure. Red fluorescent materials have high luminous brightness, wide excitation and narrow emission range, such as figure 2 There is a wide ...

Embodiment 2

[0043] According to the preparation example described in Example 1, the reducing atmosphere is CO, and the red fluorescent material can be synthesized by heating to 1200-1500° C. in a rapid heating device for 4-8 minutes.

Embodiment 3

[0045] A white LED light-emitting device: the white LED light-emitting device includes a packaging substrate, an InGaN semiconductor chip, UV quick-drying resin glue, and two phosphors that can effectively absorb the blue light emitted by the LED chip and release green and red light; The fluorescent powder is the fluorescent material synthesized in the above-mentioned embodiment 1, and its chemical composition formula is Sr 2 sc 0.5 Ga 1.5 o 5 :xEu 2+ , where x=0.02. Among them, the luminescence peak wavelength of the InGaN semiconductor core is ~450nm, and the green phosphor is Ba 2 SiO 4 :Eu 2+ . The two fluorescent powders are evenly dispersed in the UV quick-drying resin glue, covered on the chip by coating or dispensing, and the circuit is connected to obtain the white LED lighting device of the present invention.

[0046] The spectrum of LED lighting devices such as Figure 4 As shown, warm white light emission is achieved. Under 20mA current, its color renderi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com