Volumetric integrated composite phase change heat storage material and preparation method thereof

A phase-change heat storage material and composite phase-change technology, applied in the field of volumetric photothermal integrated composite phase-change heat storage material and its preparation, can solve the problems of phase-change material corrosion, phase separation, poor particle stability, etc., and achieve Strong corrosion resistance, high stability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

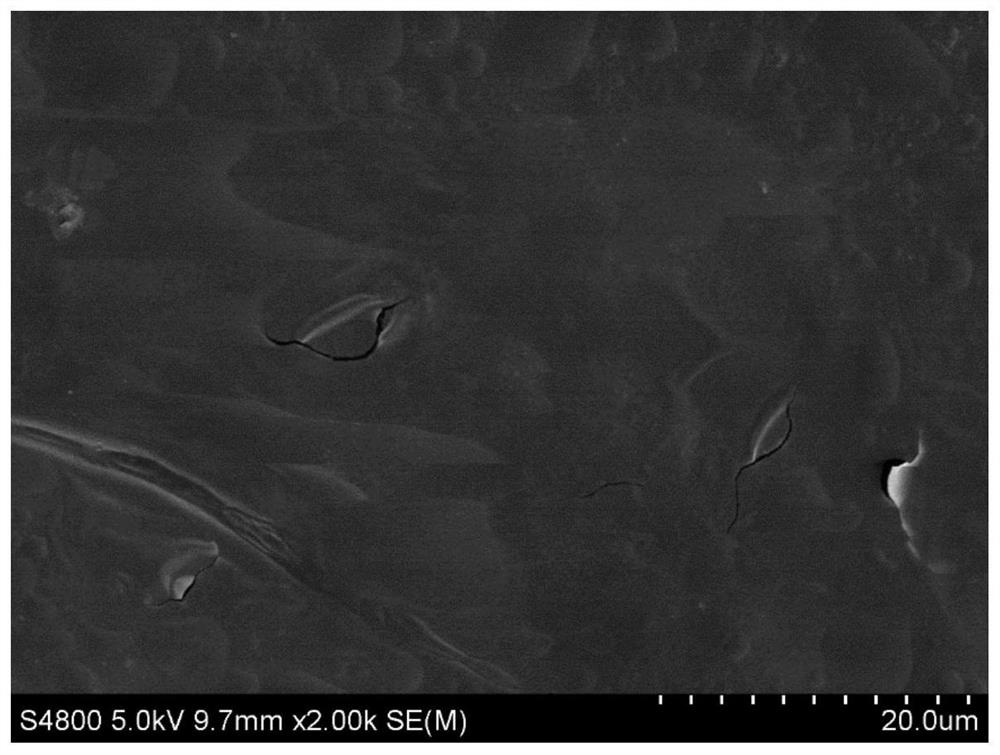

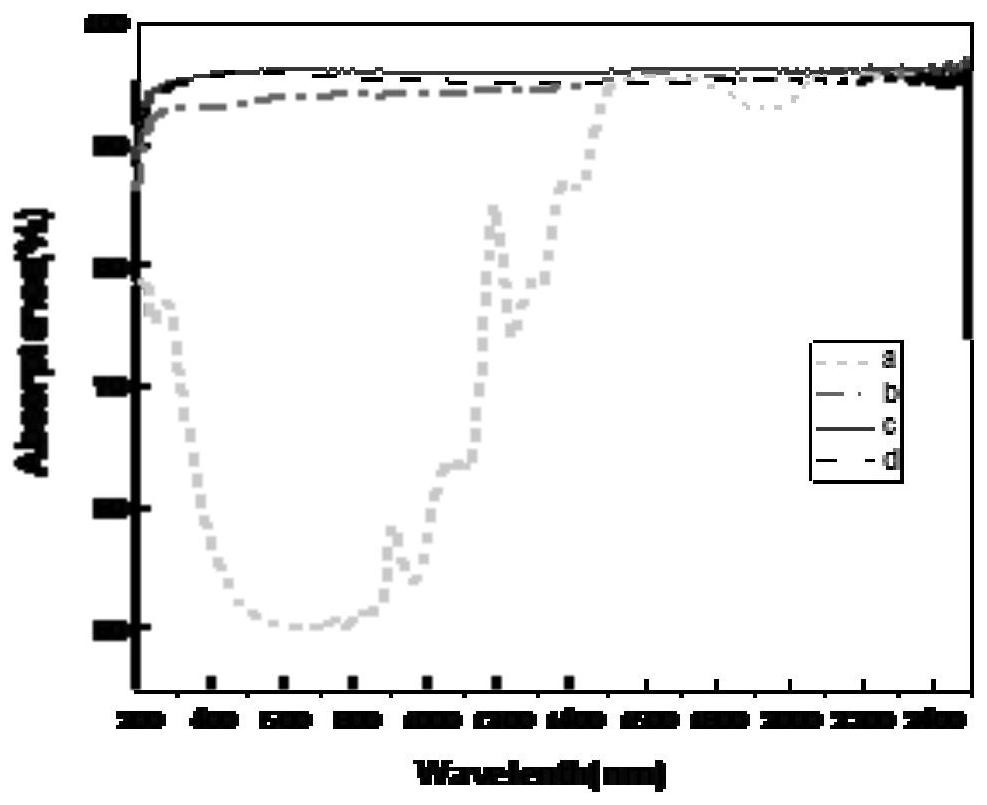

[0026] refer to figure 1 , Figure 4 , image 3 middle line a, Image 6 In line a, mix 10g of erythritol and 0g of nano-titanium nitride evenly, and then put it in an oven at 150°C for melting. After melting, transfer it to an oil bath at 130°C for mechanical stirring for 30 minutes. Vacuum degassing was carried out in a vacuum environment at 130° C. for 10 minutes. After degassing, it is poured into a mold, cooled and solidified, and then demoulded for surface grinding to obtain a volumetric photothermal integrated composite phase change heat storage material.

Embodiment 2

[0028] refer to image 3 middle b line, Image 6 In line b, mix 10g of erythritol with 0.001g of nano-titanium nitride evenly, then put it into an oven at 150°C for melting, transfer it to an oil bath at 130°C for mechanical stirring for 30 minutes after melting, and put it into the Place in a vacuum environment at 130°C for vacuum degassing for 10 minutes. After degassing, it is poured into a mold, cooled and solidified, and then demoulded for surface grinding to obtain a volumetric photothermal integrated composite phase change heat storage material.

Embodiment 3

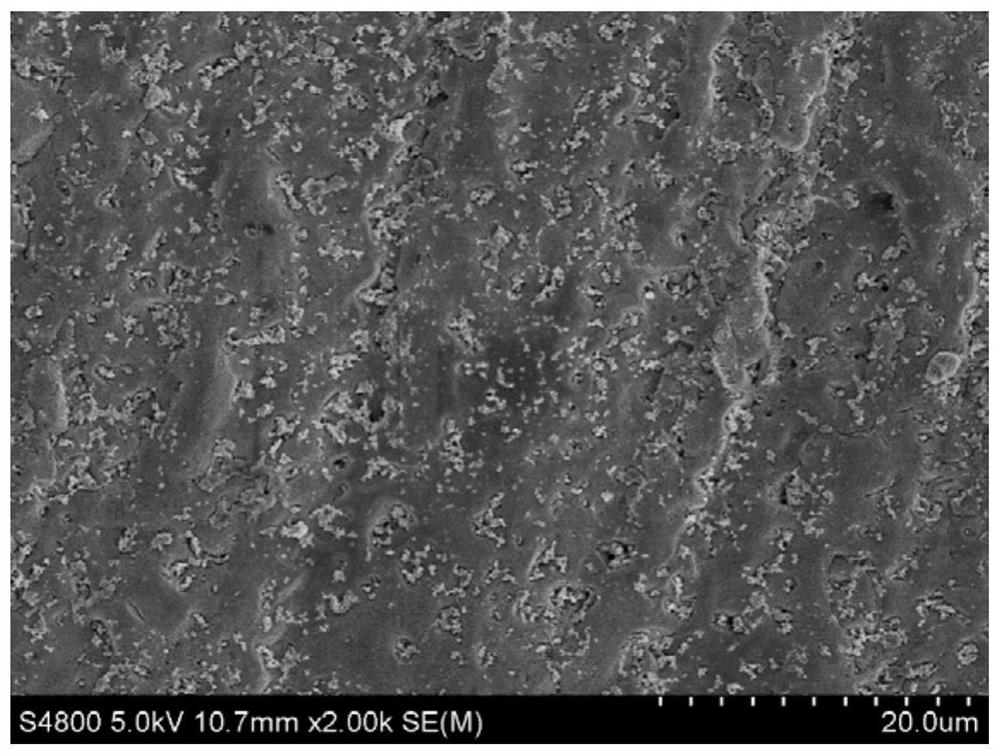

[0030] refer to image 3 middle line c, Image 6 In line c, mix 10g of erythritol and 0.1g of nano-titanium nitride evenly, then put it in an oven at 150°C for melting, transfer it to an oil bath at 130°C for mechanical stirring for 30 minutes after melting, and put it into the Place in a vacuum environment at 130°C for vacuum degassing for 10 minutes. After degassing, it is poured into a mold, cooled and solidified, and then demoulded for surface grinding to obtain a volumetric photothermal integrated composite phase change heat storage material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com