Preparation method and application of PTFE-based film of offshore wind power single pile for preventing marine organism adhesion

A PTFE and offshore wind power technology, which is applied in the field of anti-marine bioadhesion of offshore wind power monopile based on PTFE membrane preparation, can solve the problems of no obvious adhesion of biological community mucous membranes, no solution to prevent marine fouling bioadhesion, etc. Good dimensional stability, good dimensional stability, the effect of not easy to change performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method for preparing an offshore wind power single pile to prevent marine organisms from adhering based on a PTFE membrane provided in this embodiment includes

[0049] (1) Blending, pre-pressing, and pressing to obtain PTFE rods

[0050] Infiltrate the PTFE resin with aviation kerosene, which has the function of softening PTFE, and blend the infiltrated PTFE resin. The PTFE resin used is the particle powder of polytetrafluoroethylene dispersion resin, and the aviation kerosene and PTFE resin are blended at a mass ratio of 20:100. Injection; through hot pre-pressing and hot pushing at a temperature of 60°C, a speed of 25m / min, and a pressure of 5MPa, a PTFE rod of Ф17mm for monomer polymerization was obtained;

[0051] (2) PTFE membrane fusion polymerization

[0052] The monomer-polymerized PTFE rods are fused and polymerized under the action of hot calendering. The hot calendering temperature is 60°C and the speed is 25m / min. The PTFE rods are stretched laterally un...

Embodiment 2

[0060] What this embodiment provides is an application of Embodiment 1, including

[0061] (1) Application of uninstalled offshore wind power monopile

[0062] Directly wrap the PTFE-based film on the surface of the anti-corrosion layer of the underwater section of the single pile and the section of the wave splashing section. The junction of the mud entry section and the underwater section of the single pile is used as the starting point of film bonding, and the single pile is installed from bottom to top. Winding and bonding, the overlapping width of the film and the film is 20-50mm, and the overlapping is tightly compacted;

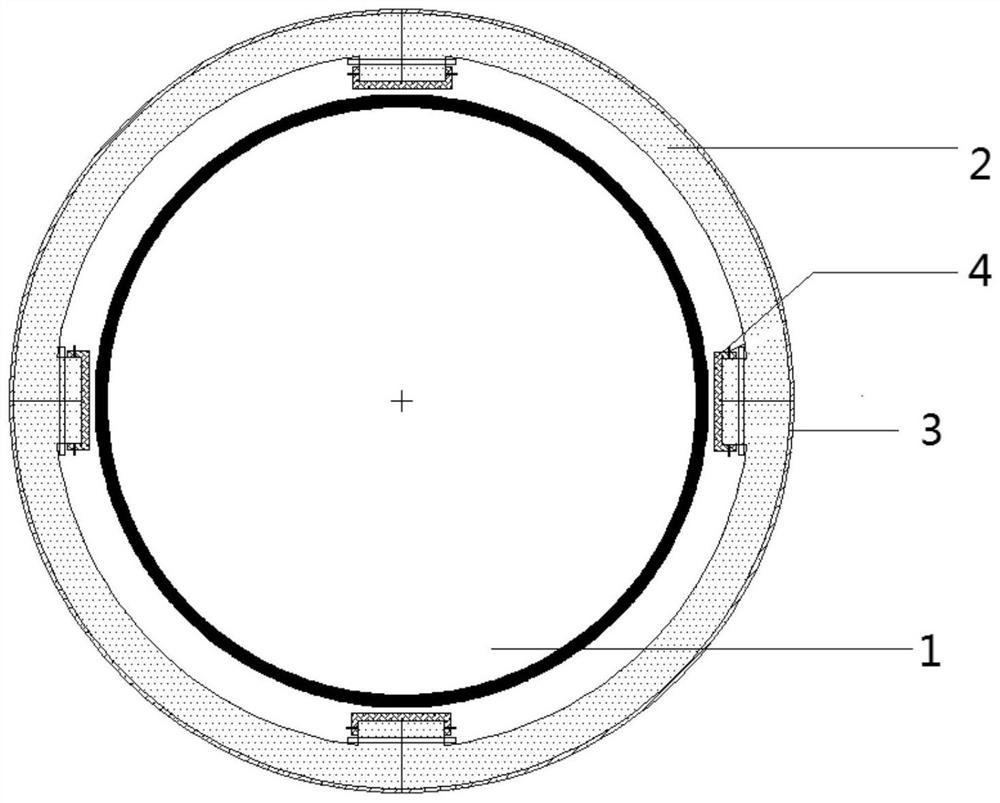

[0063] (2) Application of offshore wind power single piles that have been put into operation

[0064] According to the design of the outer diameter of the offshore wind power single pile 1 in actual application, the fiberglass steel sheet assembly 2 suitable for assembly at the offshore application site is prepared through the glass fiber reinforced p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com