Coating sand mill for producing environment-friendly low-carbon coating

A sand mill and paint technology, which is applied in cleaning methods and utensils, smoke removal, grain treatment, etc., can solve the problems of paint can not achieve good conveying effect, unfavorable paint discharge and conveying, and poor cylinder cooling effect, etc. Achieve the effect of improving the grinding effect, reducing the failure rate and ensuring the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

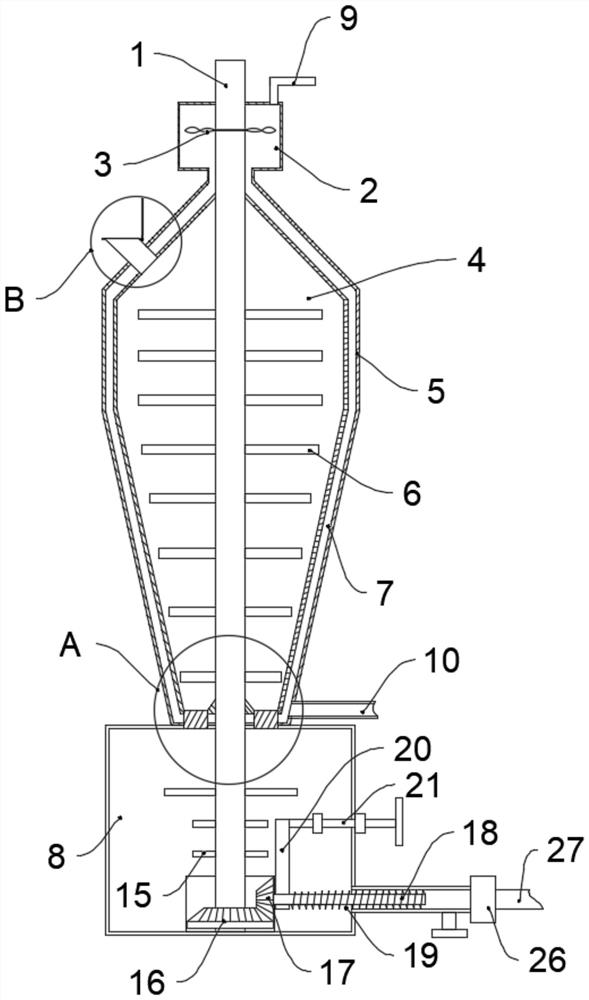

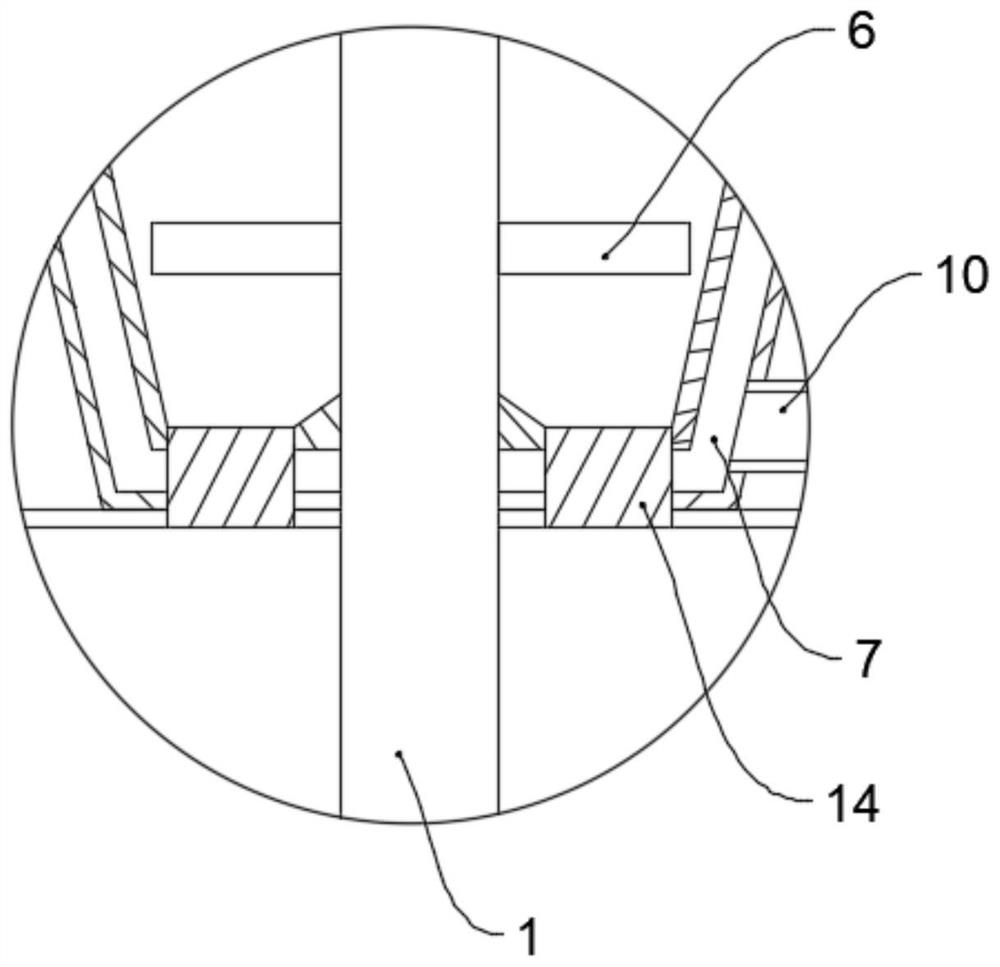

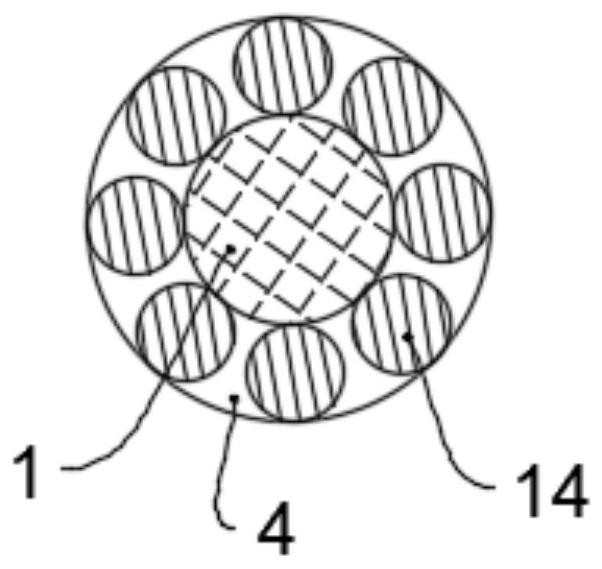

[0029] like Figure 1-5 As shown, a paint sand mill for producing environmentally friendly low-carbon paints includes a motor output end 1 fixedly connected to the motor, a cold water chamber 2 is provided at the lower part of the motor output end 1, and a drainage impeller 3 is arranged inside the cold water chamber 2 , the drainage impeller 3 is fixedly sleeved on the motor output end 1, and the drainage impeller 3 can be driven to rotate while the motor output end 1 is rotating. Sanding balls, the side of the motor output end 1 is fixedly connected with a plurality of grinding sheets 6, and the grinding sheets 6 rotate with the rotation of the motor output end 1, and the outer side of the sanding cylinder 4 is provided with a cooling outer partition 5, and the cooling outer A water cooling layer 7 is arranged between the partition plate 5 and the sand grinding cylinder 4, the upper end of the water cooling layer 7 communicates with the lower side of the cold water chamber 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com