Test equipment and test method for evaluating uniform corrosion of metal materials

A test equipment, a technology of uniform corrosion, applied in the direction of analysis of materials, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problem of inaccurate test results, and achieve the effect of improving accuracy and scientificity, and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Test equipment for evaluating uniform corrosion of metallic materials

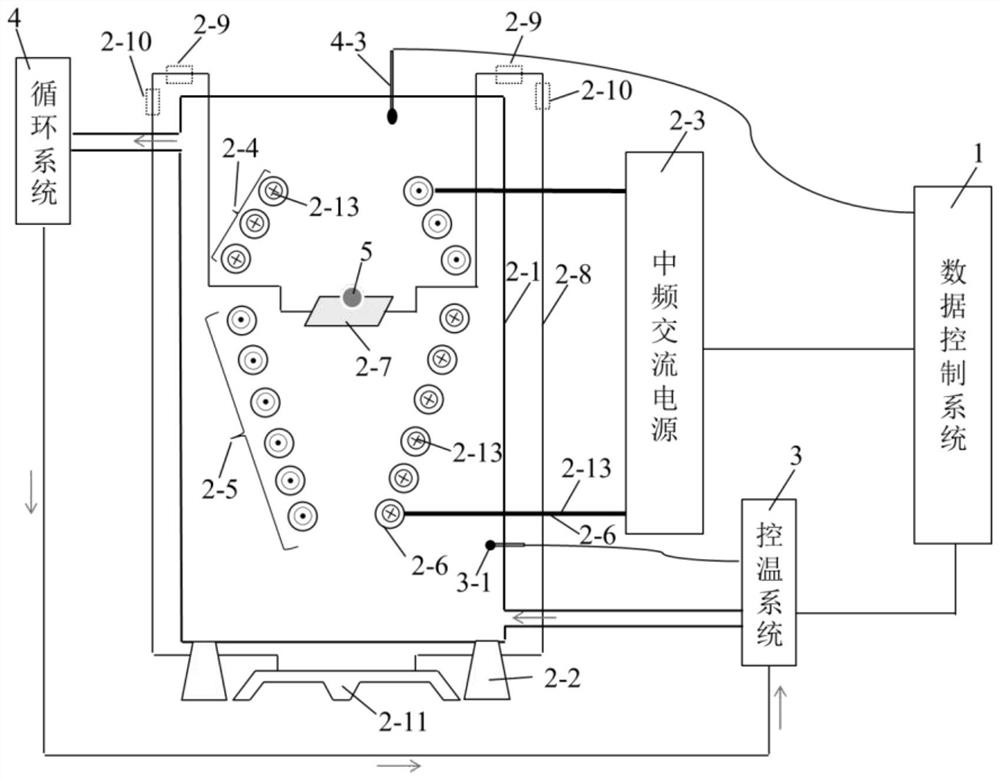

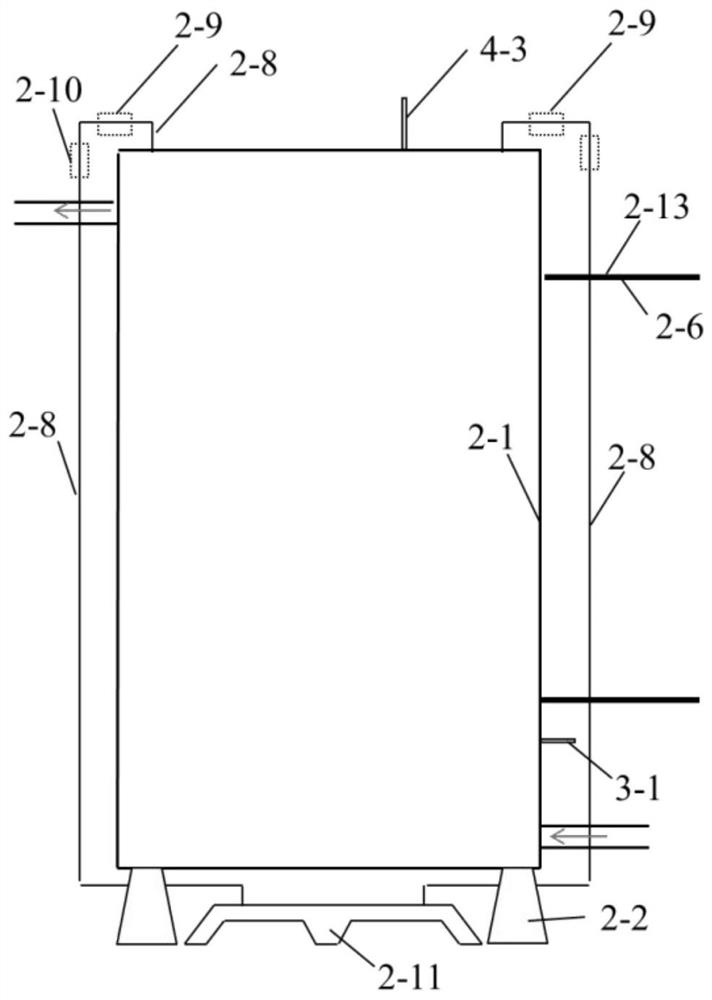

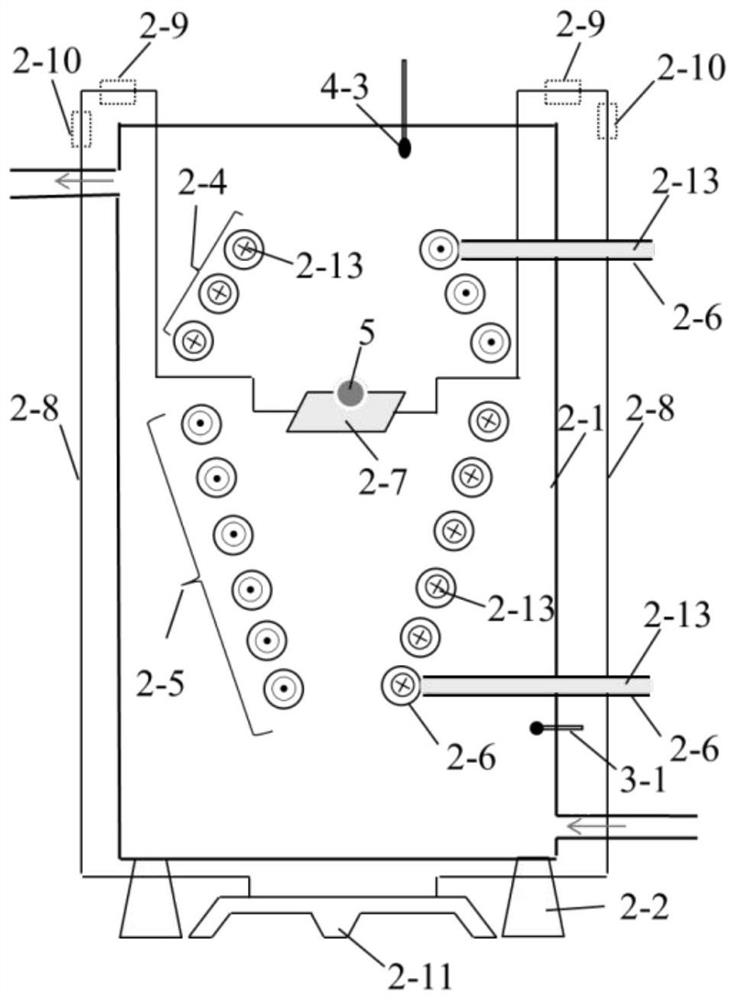

[0031] Refer to attached Figure 1-5 , the suspension-type test equipment for evaluating the uniform corrosion of metal materials in this embodiment is composed of the following systems and devices: data control system 1, suspension system 2, temperature control system 3 and circulation system 4.

[0032] Wherein, the suspension system 2 includes a ceramic chamber 2-1, a chamber support 2-2 for supporting the chamber 2-1, an intermediate frequency AC power supply 2-3, a coil and a weighing device. Wherein the coil includes a stable coil 2-4 and a suspension coil 2-5, and the coil is a copper wire 2-13 wrapped with a coil insulating layer 2-6; the weighing device includes an electronic balance 2-11, a support 2-8, and is arranged on the support The horizontal telescopic knob 2-9 on the 2-8 and the vertical telescopic knob 2-10 and the horizontal tray 2-7.

[0033] Specifically, in this em...

Embodiment 2

[0041] Embodiment 2 test method

[0042] The test method of the present embodiment is based on the test equipment in embodiment 1, specifically comprises the following steps:

[0043] 1) Prepare the sample 5 to be tested, and place the sample 5 to be tested on the tray 2-7.

[0044] 2) Adjust the bracket, adjust the horizontal telescopic knob 2-9 and the vertical telescopic knob 2-10 so that the sample 5 to be tested is located in the middle position between the suspension coil 2-5 and the stable coil 2-4, which is convenient for subsequent stable suspended.

[0045] 3) The electronic balance 2-11 sends the weight data applied to the pallet 2-7 by the sample 5 to be tested to the control system 1, and the control system 1 adjusts the size of the power supply 2-3 according to the received weight data to control the sample to be tested. 5 is gradually separated from the tray 2-7, and the test sample 5 is finally suspended between the suspension coil 2-5 and the stabilization c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com