Multi-oil-cylinder pushing method for large-size rock mass structural surface shear test based on bracket structure

A technology of shear test and structural surface, which is applied in the field of indoor physical and mechanical tests, can solve problems such as damage, and achieve the effect of reducing investment, low cost and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

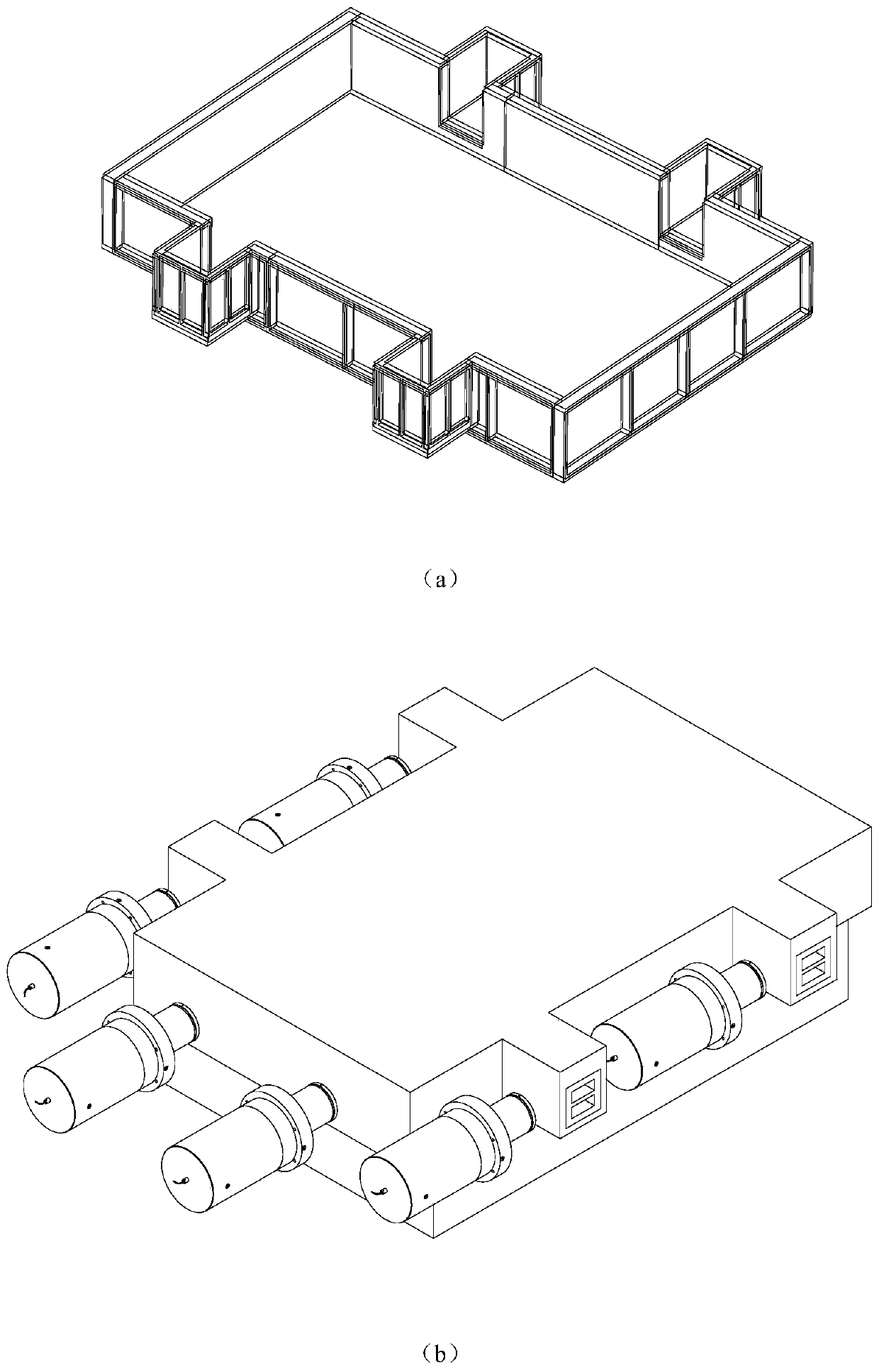

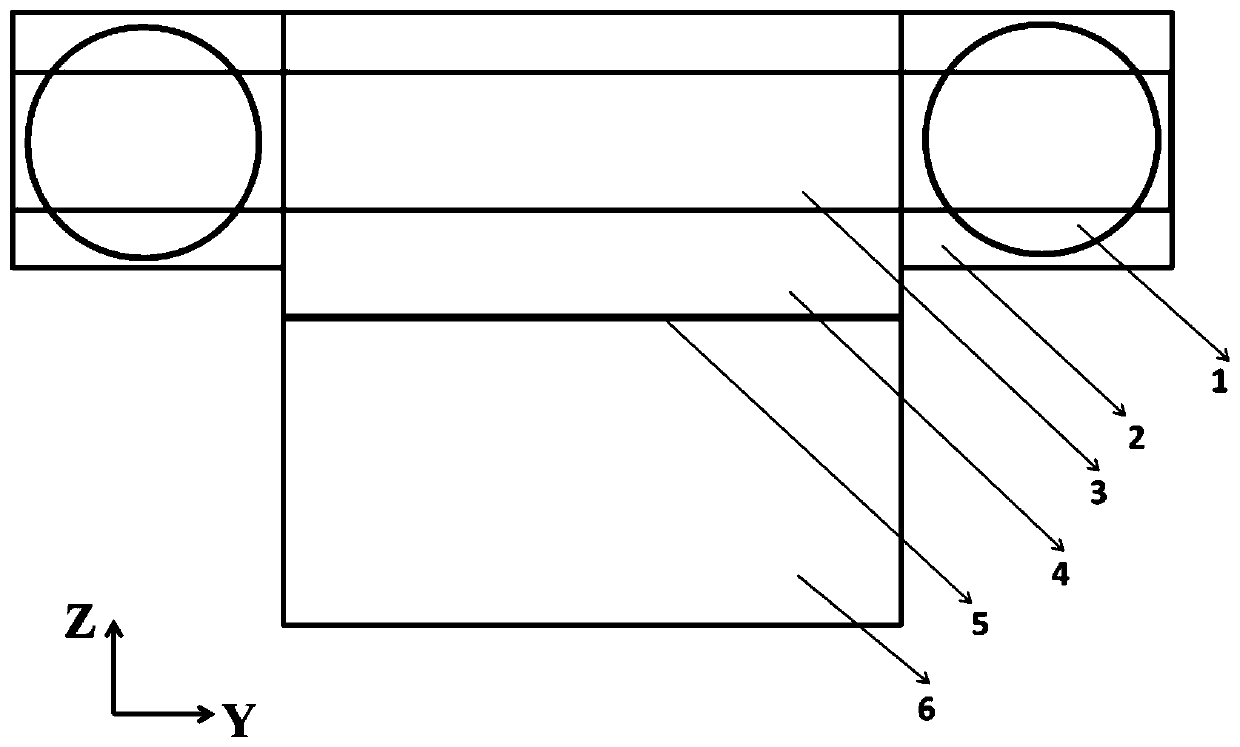

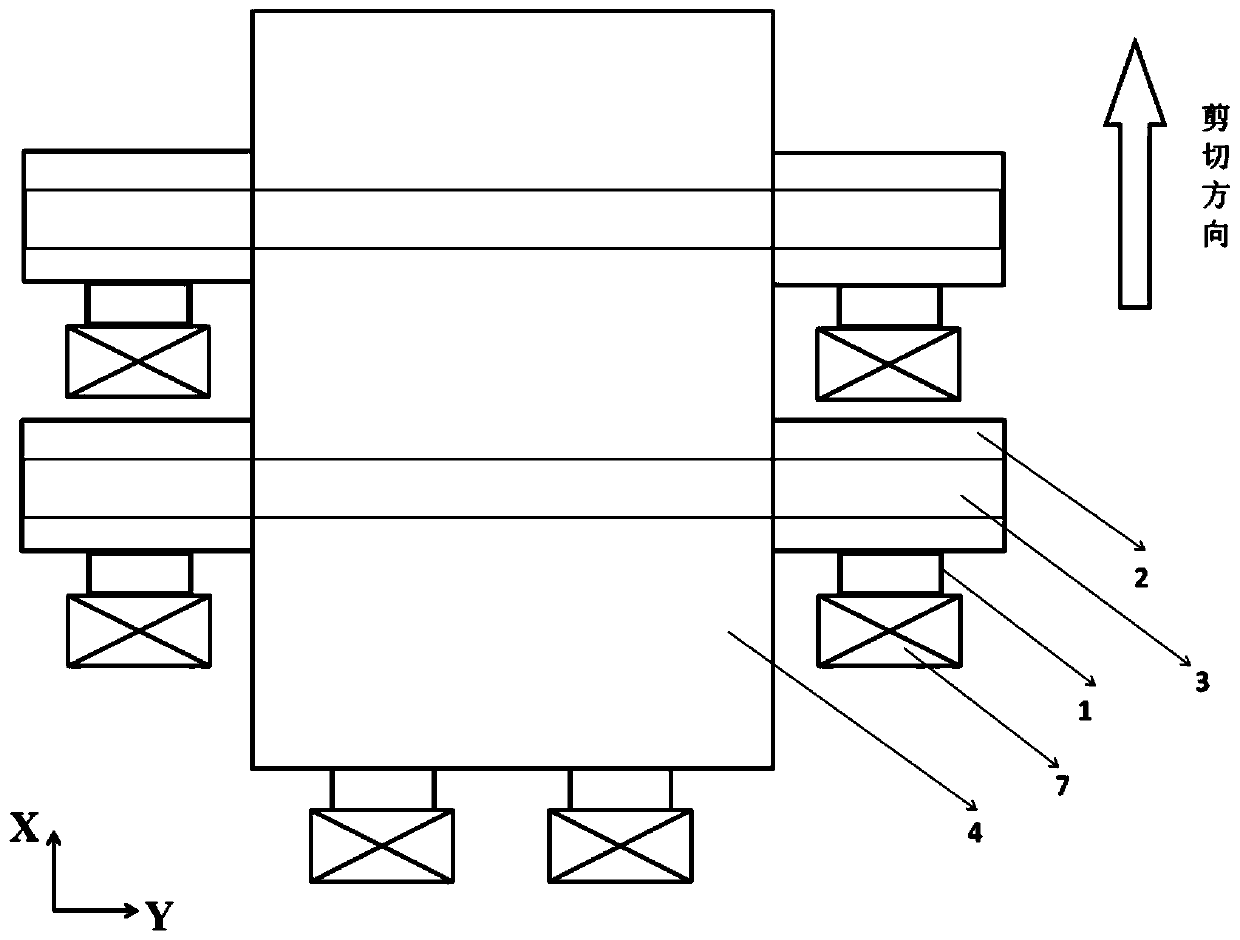

[0028] refer to Figure 1 ~ Figure 3 , a kind of multi-cylinder pushing method of the shear test of large-scale rock mass structural surface based on corbel structure, described method comprises the following steps:

[0029] (1) According to the formulation and maintenance specifications of large-scale concrete samples, use cuboid steel molds to cast large-scale samples under the rock mass structure surface, and the length, width, and height of the samples are L, W, and H;

[0030] (2) According to the size of the sample on the structural surface of the rock mass, a concrete pouring steel mold with a special structure is designed. figure 1 As shown, the overall shape is a cuboid, with N pairs of protruding small cuboid structures on both sides, N is an integer, and N≥2;

[0031] (3) Utilize welding technology to fix N blocks of rectangular parallelepiped steel plates in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com