Adjustable wall formwork device and construction method

A construction method and an adjustable technology, which can be applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, and on-site preparation of building components, which can solve the waste of materials, the influence of manual installation errors, etc. problems, to achieve the effect of reliable connection, strong applicability, guarantee of flatness and linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

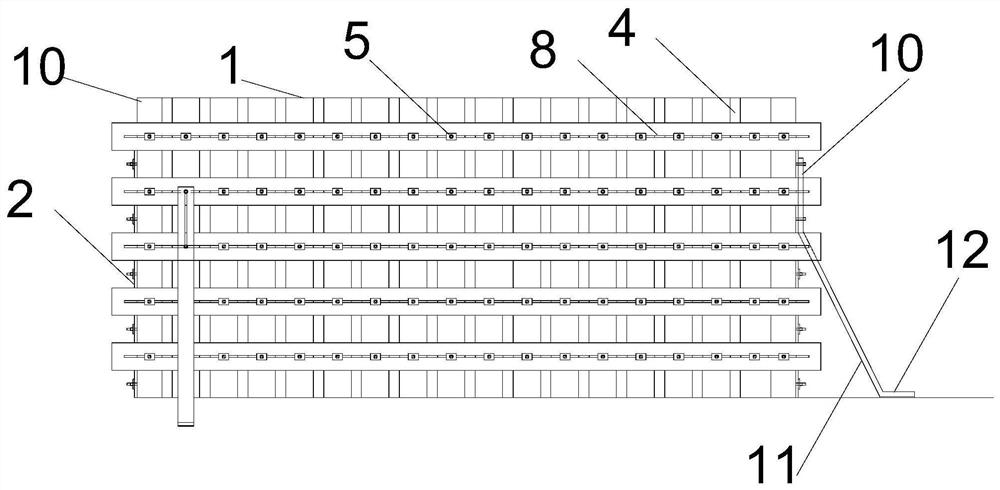

[0034] Such as figure 1 As shown, an adjustable wall formwork device includes bamboo plywood 1, right-angle steel slats 2, vertical corrugations 4, horizontal corrugations and steel diagonal braces, bamboo plywood 1 is spliced into a rectangular outline of the outer wall; right-angle steel slats 2 The right-angled surface is provided with staggered rebars, and the four right-angled sides of the right-angled steel strips 2 are attached to the bamboo plywood 1; The positions of the rebars are horizontally aligned, and the positions of the vertically corrugated rebars 5 on adjacent two surfaces are staggered; grooves are provided on the horizontal corrugations, and the width of the horizontal corrugated grooves is consistent with the diameter of the vertical corrugated rebars 5. The vertical corrugated rebar 5 is set through the grooves and fixed by steel plates with holes and nuts; the steel braces include the upper section 11, the middle section 12 and the lower section 12 wh...

Embodiment 2

[0040] Please continue to refer figure 1 , the present invention also provides a construction method for an adjustable wall formwork, the construction method comprising the following steps:

[0041] Step S1, laying out wires on the ground to locate the outer edge of the cast-in-place wall, placing the pre-enclosed columnar bamboo plywood 1 at the location, and attaching the right-angled steel strips 2 with staggered rebars to the sides of the bamboo plywood 1 The four right-angled sides are fixed;

[0042] Step S2, horizontal flutes and vertical flutes 4 are arranged at intervals respectively on the outside of the bamboo plywood 1, grooves are provided on the horizontal flutes, and rebars are provided on the vertical flutes, the diameter of the rebars is consistent with the width of the grooves, and the grooves on the same horizontal line The vertical corrugated rebar 5 is set through the groove, and after being adjusted to a suitable distance, it is fixed by a steel plate wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com