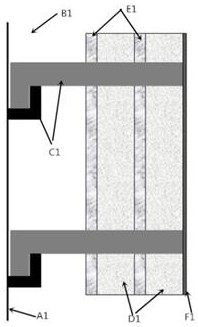

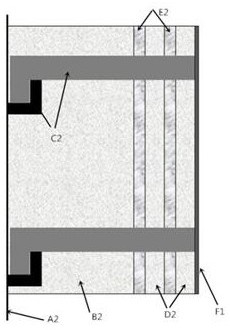

Composite insulating layer construction method

A construction method and insulation layer technology, applied in insulation, building components, fire protection, etc., can solve the problems of wall damage, time-consuming and labor-intensive demolition, gaps between sheets, etc., to ensure insulation quality, good insulation effect, and fast construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] The following is the specific construction method of the present invention, which is not a limitation to the claims. Changes made by those skilled in the art based on the relevant knowledge in the field are also within the protection scope of the present invention.

[0029] The plate used in the present invention is a PVC exterior wall hanging plate, the combustion performance is B2 level, and the thickness is 6mm;

[0030] For buildings in Jinan (North) area, according to the construction requirements, a layer of 30cm thick insulation layer needs to be constructed on the outer wall of the six-storey building. After the building material processing factory produces the 1.0m*1.0m outer panel, the four front-end protruding connecting rods are bonded At the four corners of the outer plate, the end without protrusions is the bonding end;

[0031] Then mix polyurethane material A and material B evenly and spray it to the inner surface quickly, the foaming time is 10-20s, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com