High-thermal-conductivity radiation refrigeration fiber, preparation method thereof and fabric

A technology of radiative cooling and high thermal conductivity, applied in the direction of braided fabrics, fiber treatment, fiber chemical characteristics, etc., can solve the problems of blocking the heat dissipation of the skin, limiting the cooling effect of fabrics, and difficulty in large-scale production, so as to enhance the effect of radiative cooling, Improve heat conduction and heat dissipation capabilities, improve the effect of reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

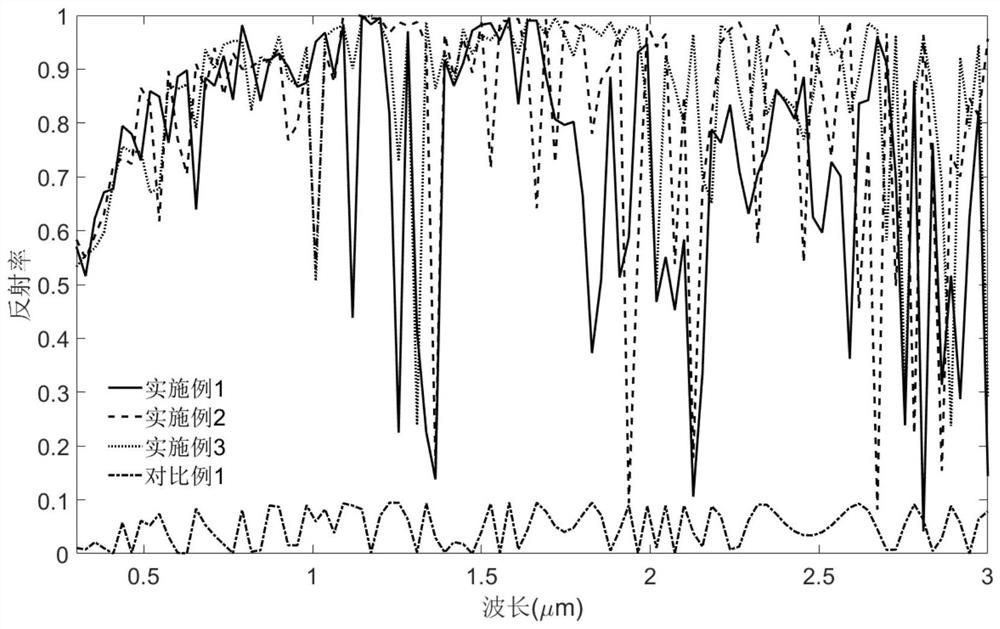

Embodiment 1

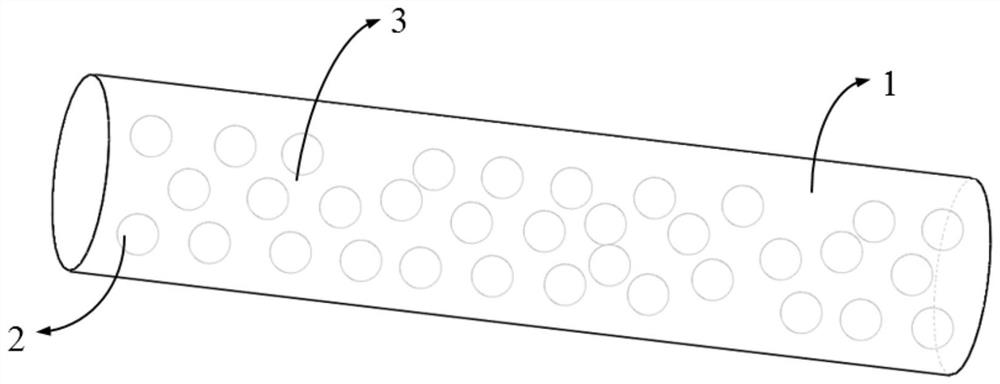

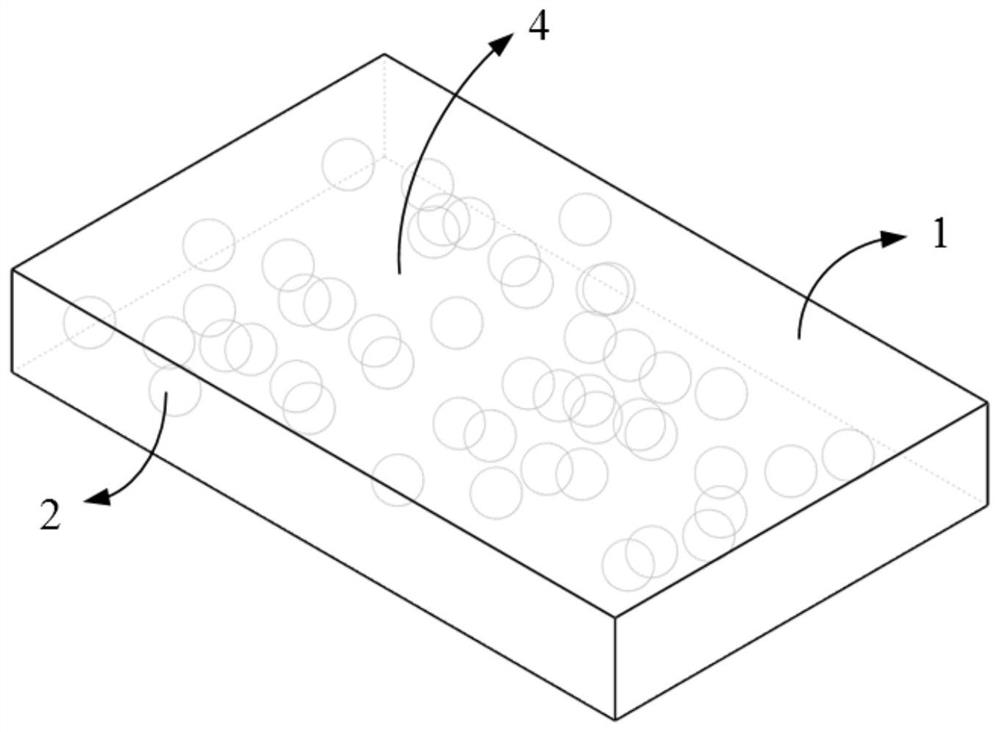

[0043] The polymer base material is PVDF, the high thermal conductivity micro-nano particles are aluminum nitride, and the particle radius is 0.3±0.03 μm. Due to the high thermal conductivity requirements, the volume fraction of high thermal conductivity particles is selected to be at most 50%, and the high thermal conductivity radiation cooling fiber is obtained, and The thickness of the fabric made of fibers was 80 μm.

[0044] Preparation process:

[0045] (1) Composite material preparation: Add 270g of PVDF particles into a pulverizer to pulverize them into powder and uniformly mix with 730g of aluminum nitride particles, pour the mixed powder into a twin-screw extruder, set the temperature at 290°C, and polymerize at high temperature The molten material is uniformly mixed with the heat-conducting particles, and the set pressure is 4.5MPa. The mixed melt is extruded and solidified in a water bath to form a casting belt, which is led to a pelletizer to cut to form a composi...

Embodiment 2

[0051] The polymer base material is PVDF, the high thermal conductivity micro-nano particles are aluminum nitride, and the particle radius is 0.3±0.03 μm. Due to the high thermal conductivity requirements, the volume fraction of high thermal conductivity particles is selected to be at most 50%, and the high thermal conductivity radiation cooling fiber is obtained, and The thickness of the fabric made of fibers was 150 μm.

[0052] Preparation process:

[0053] (1) Composite material preparation: Add 270g of PVDF particles into a pulverizer and pulverize them into powder and mix them evenly with 730g of aluminum nitride particles, pour the mixed powder into a twin-screw extruder, set the temperature at 270°C, and polymerize at high temperature The molten material is uniformly mixed with the heat-conducting particles, and the set pressure is 4.5MPa. The mixed melt is extruded and solidified in a water bath to form a casting belt, which is led to a pelletizer to cut to form a com...

Embodiment 3

[0059] The polymer base material is PVDF, the high thermal conductivity micro-nano particles are aluminum nitride, and the particle radius is 0.3±0.03 μm. Due to the high thermal conductivity requirements, the volume fraction of high thermal conductivity particles is selected to be at most 50%, and the high thermal conductivity radiation cooling fiber is obtained, and The thickness of the fabric made of fibers was 300 μm.

[0060] Preparation process:

[0061] (1) Composite material preparation: Add 270g of PVDF particles into a pulverizer and pulverize them into powder and mix them evenly with 730g of aluminum nitride particles, pour the mixed powder into a twin-screw extruder, set the temperature at 270°C, and polymerize at high temperature The molten material is uniformly mixed with the heat-conducting particles, and the set pressure is 4.5MPa. The mixed melt is extruded and solidified in a water bath to form a casting belt, which is led to a pelletizer to cut to form a com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com