Manufacturing method of sliding part, sliding part and textile machine using same

A manufacturing method and technology for sliding parts, which are applied to mechanical equipment, processing of textile materials, rotating parts resistant to centrifugal force, etc., can solve problems such as the influence of powder metallurgy process implementation procedures, increase separate procedures, etc., so as to reduce the risk of combined failure and resistance. The effect of broken extension path and qualified mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

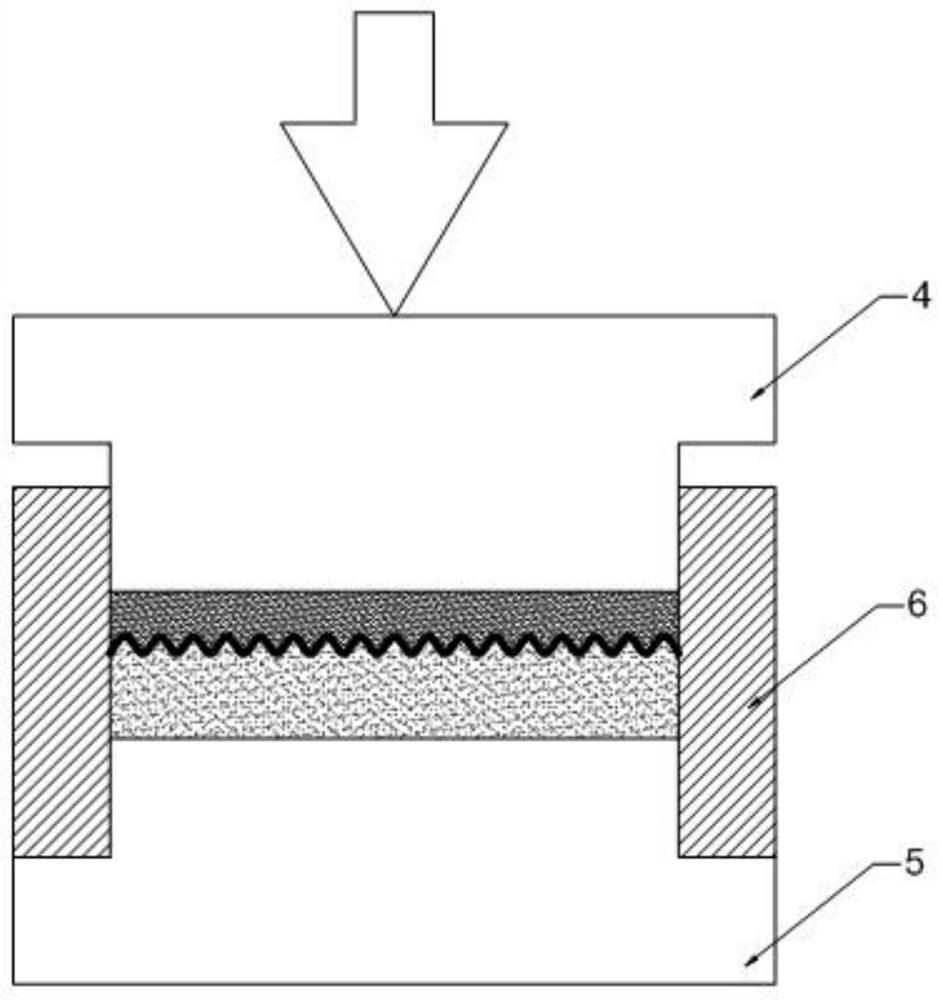

[0030] see first image 3 , in this example image 3 In the hot pressing die shown, the powder metallurgy method is used to make a bi-material or multi-material planar slide, which is used as a sliding bearing in textile machinery. The hot pressing mold structure includes an upper template 4, a lower template 5 and a mold cover 6, and the upper template 4, the lower template 5 and the mold cover 6 encircle the powder raw material feeding cavity and the molding cavity of the slider.

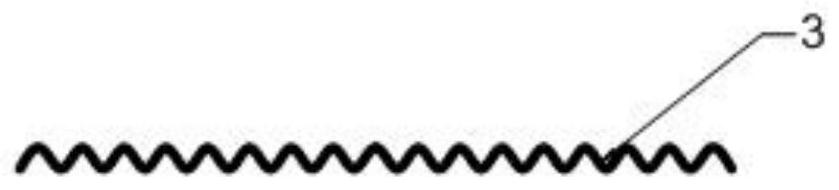

[0031] combine Figure 1-Figure 3 , the method for making the slider includes: using the second powder material 2 as the powder raw material for the supporting material layer, using the first powder material 1 as the raw material for the working material layer, laying materials in order, and using the second powder material as the powder raw material for the supporting material layer 2 on the bottom, the first powder material 1 as the raw material of the working material layer is on the top, and...

Embodiment 2

[0038] see still Figure 1-Figure 4 , the preparation target, the hot pressing mold used and the process adopted in this embodiment are basically the same as those in Example 1, and the interface structure template 3 adopted is also the same, the difference is that in the sequential laying of materials, The laid second powder material 2 and the first powder material 1 are both mixed with a binder with a volume content of 8%, and the second powder material 2, the interface construction template 3, and the first powder material 1 are laid in sequence. After that, degreasing and sintering are carried out. During the degreasing process, the interface structure template 3 is decomposed and removed together with the binder.

[0039] The final temperature of the above-mentioned degreasing process in this embodiment is based on the fact that the adhesive and the interface structure template 3 can be completely decomposed, and the processes of pressurization, degreasing and sintering i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com