A bonding device and bonding method for inclined butt joints

A technology for butt joints and bonding, which is applied in the direction of connecting components, material gluing, mechanical equipment, etc., can solve the problems of difficulty in precise control of the thickness of the adhesive layer, cannot be relatively far away, and it is difficult to accurately control the thickness of the adhesive layer, etc., to reduce bonding The risk of failure, the effect of saving investment and reducing the probability of scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

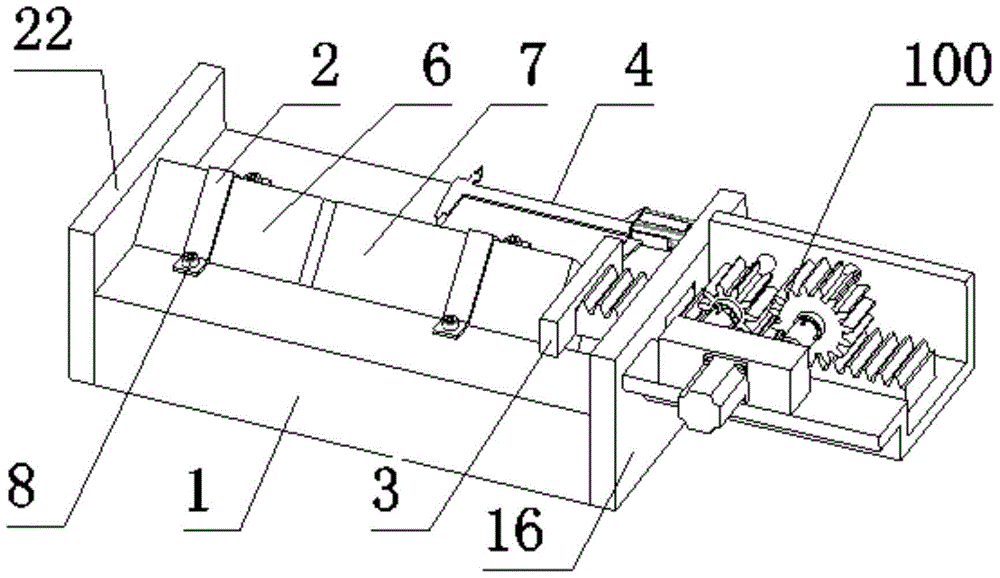

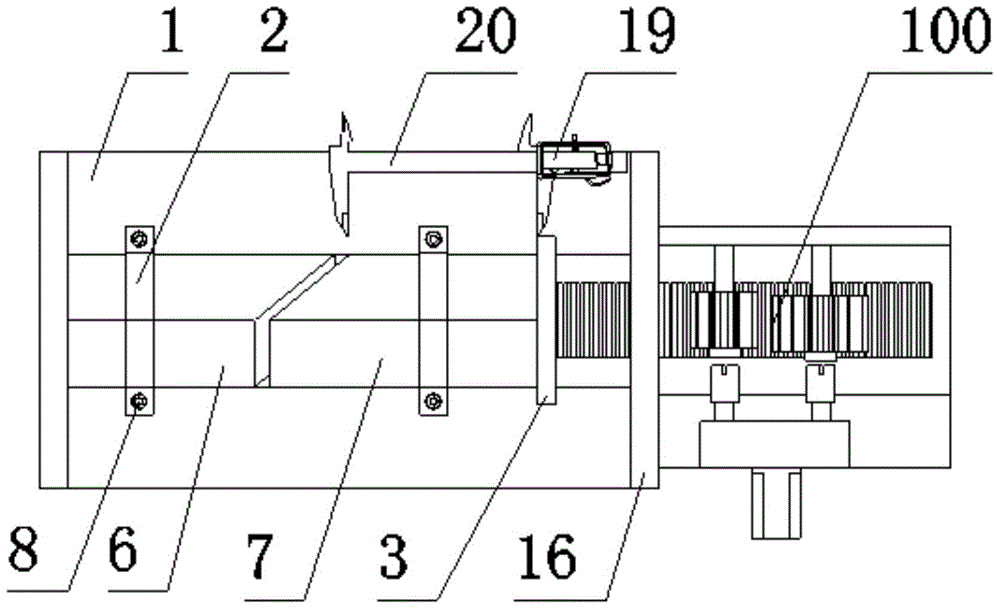

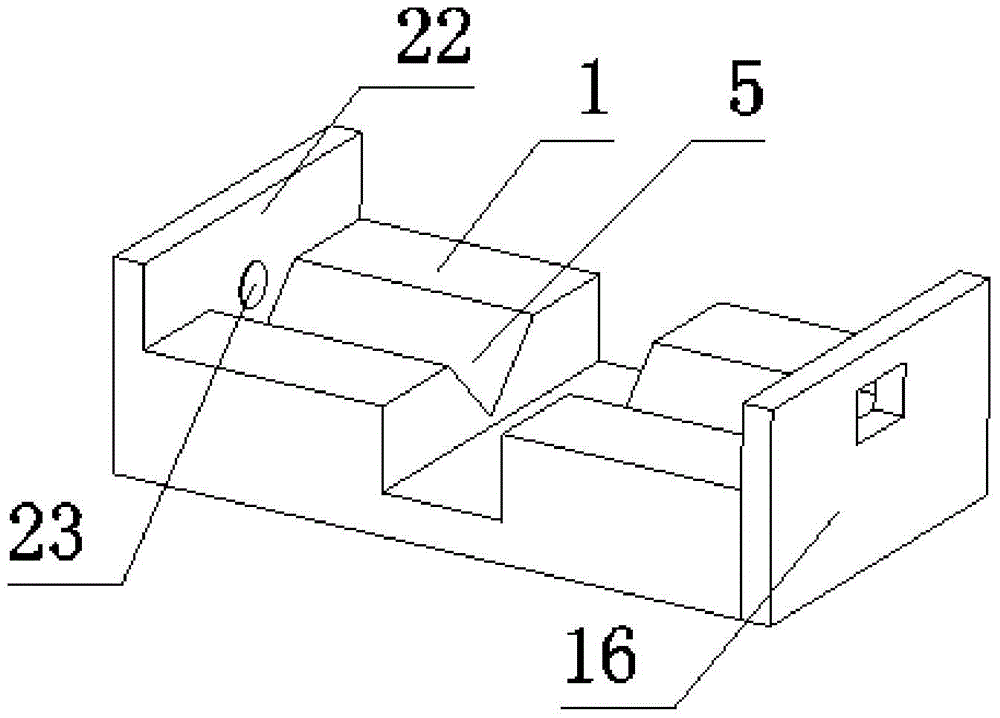

[0059] Such as figure 1 , figure 2 As shown, a bonding device for oblique butt joints of the present invention includes a base 1 , a fixing bead 2 , a top block 3 , a position measuring mechanism 4 , a driving mechanism 100 and a controller. As a preference, the base 1 is made of metal material. see also image 3 The base 1 is provided with a V-shaped positioning groove 5, and the first joint 6 and the second joint 7 to be bonded are placed in the V-shaped positioning groove 5. The V-shaped positioning groove 5 is arranged in two sections, and there is an operating space between them, so that the bonding part of the first joint 6 and the second joint 7 does not contact the base 1, which can prevent the glue from touching the base 1, thereby preventing the glue from touching the base 1. To protect the role of base 1. The fixed bead 2 is fixed on both sides of the V-shaped positioning groove 5 of the base by screws 8 , so that the middle of the fixed bead 2 is pressed again...

Embodiment 2

[0068] Compared with Embodiment 1, this embodiment adopts a different driving mechanism 100 . Such as Figure 9 As shown, in this embodiment, the driving mechanism 100 includes a tightening screw 24 and a rotary handle, the tightening screw 24 is installed on the right baffle 16 of the base, and is connected with the threaded hole on the right baffle 16 In cooperation, the left end of the tightening screw 24 is connected to the top block 3 , and turning the rotating handle can drive the top block 3 to move left and right so as to adjust the left and right positions of the second joint 6 .

[0069] The right end of tightening screw rod 24 is a positive prism, preferably a regular octagonal prism, and the rotating handle is connected with the right end of tightening screw rod 24, which is convenient to drive the tightening screw rod 24 to rotate.

[0070] As preferably, the rotary handle adopts a disc-shaped handle 25 or a rod-shaped handle 26, such as Figure 10 , Figure 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com