Manufacturing method of mandrel part, mandrel part and textile machine using same

A manufacturing method and component technology, which is applied to mechanical equipment, gear transmission mechanisms, friction linings, etc., can solve the problems of powder metallurgy process implementation procedures, adding separate procedures, etc., to reduce the risk of failure, simple operation, and qualified mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

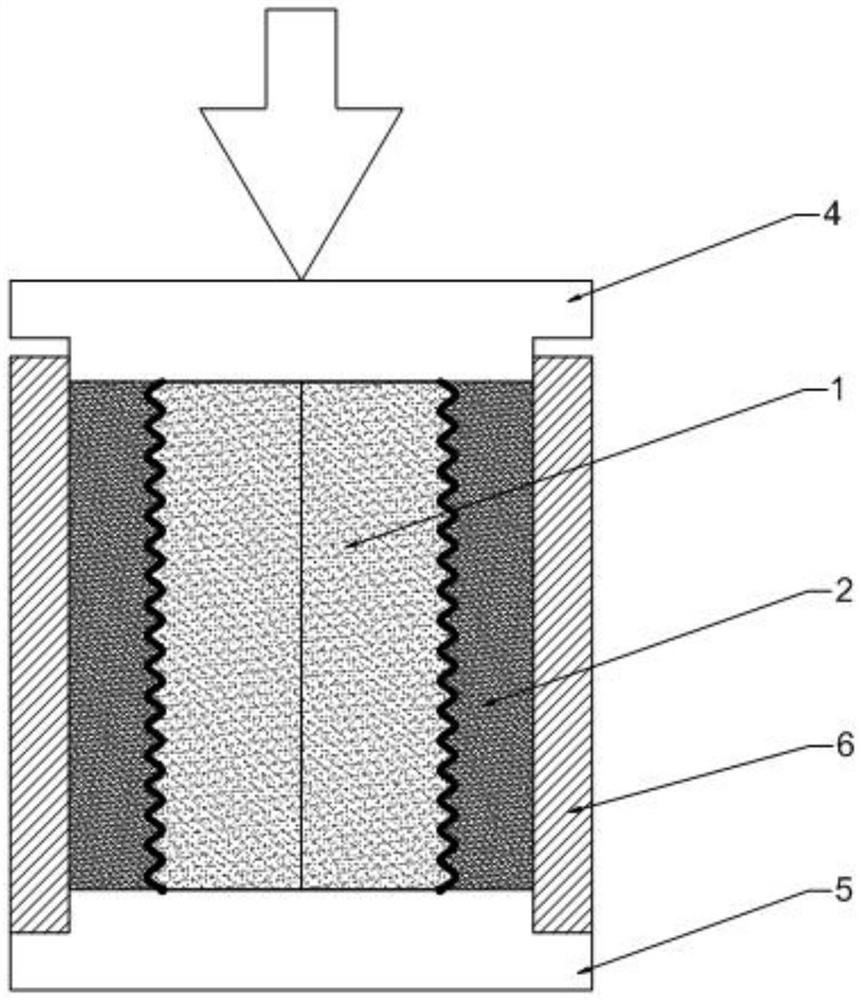

[0028] see first figure 2 , in this example figure 2 In the hot pressing mold shown, powder metallurgy is used to manufacture bi-material or multi-material cylindrical mandrel parts, which are used in textile machinery equipment.

[0029] It should be noted that, in order to make an easy-to-understand introduction to the principle of the present invention, the shape of the product in this embodiment is a regular columnar shape after the simplification of the real thing. It is easy to understand that the structural shapes of the mandrel parts in mechanical equipment may be various. For example, stepped, spliced, hollow, etc., as long as they meet the internal and external dual-material structure and can be manufactured by the method described in the present invention.

[0030] Specifically, the hot pressing mold structure includes a mold upper cover 4, a mold lower cover 5 and a ring sleeve 6, and the mold upper cover 4, the mold lower cover 5 and the ring sleeve 6 encircle ...

Embodiment 2

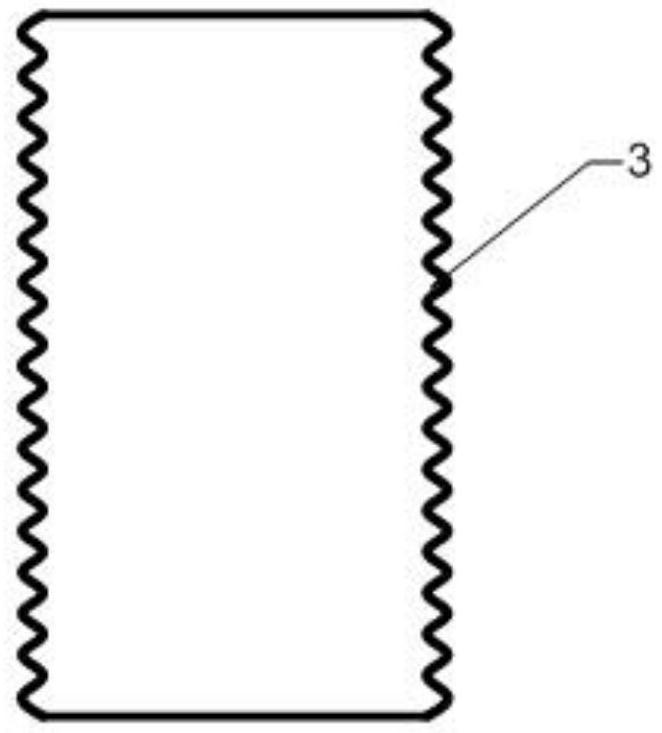

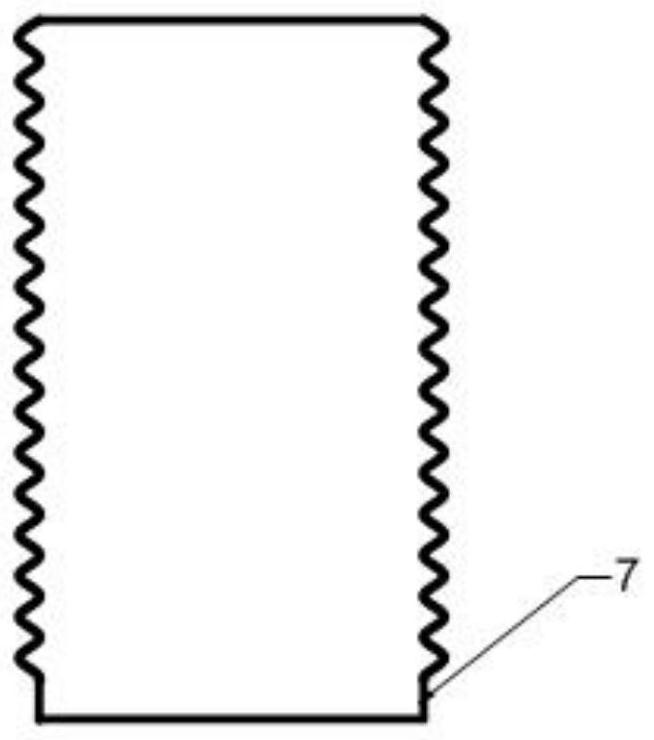

[0042] see still Figure 1-Figure 4 , the preparation target, the hot pressing mold used and the technology adopted in this embodiment are basically the same as those in Example 1, and the interface model cylinder 3 used is also the same, the difference is that in the charging according to the design specifications The laid first powder raw material 1 and the second powder raw material 2 are mixed with a molding agent with a volume content of 7%, and the interface mold cylinder 3 is placed in the center of the mold cavity and the first powder raw material 1, the second powder raw material After the powder raw material 2 is laid in the space on both sides of the interface mold cylinder 3, it is degreased and sintered. During the degreasing process, the interface mold cylinder 3 is decomposed and removed together with the molding agent.

[0043] The final temperature of the above-mentioned degreasing process in this embodiment is subject to the complete decomposition of the mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com