Stirring device for desulfurization and denitrification

A stirring device, desulfurization and denitrification technology, applied in the direction of mixer accessories, transportation and packaging, mixers, etc., can solve the problems of unqualified calcium hydroxide slurry configuration, single operation mode of the stirring device, calcium hydroxide deposited at the bottom, etc., to achieve Smooth lifting, stable operation, and reduced shaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

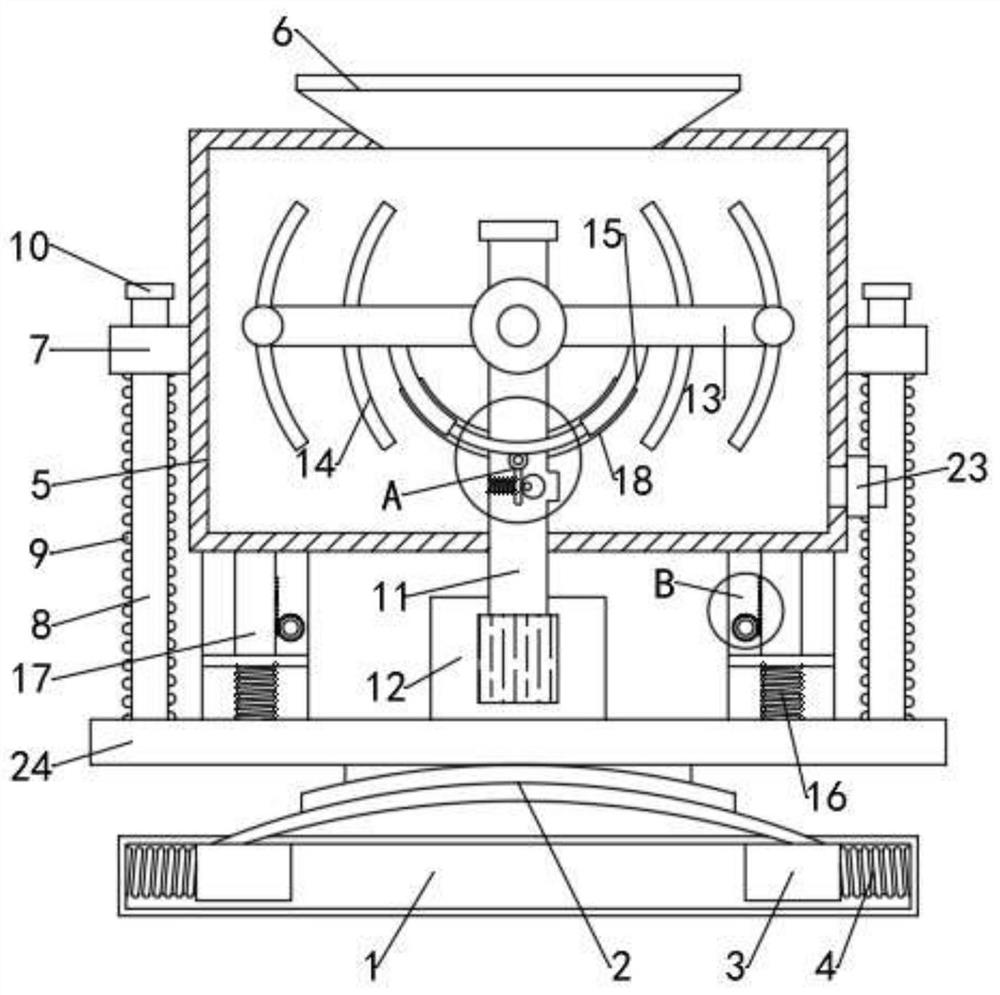

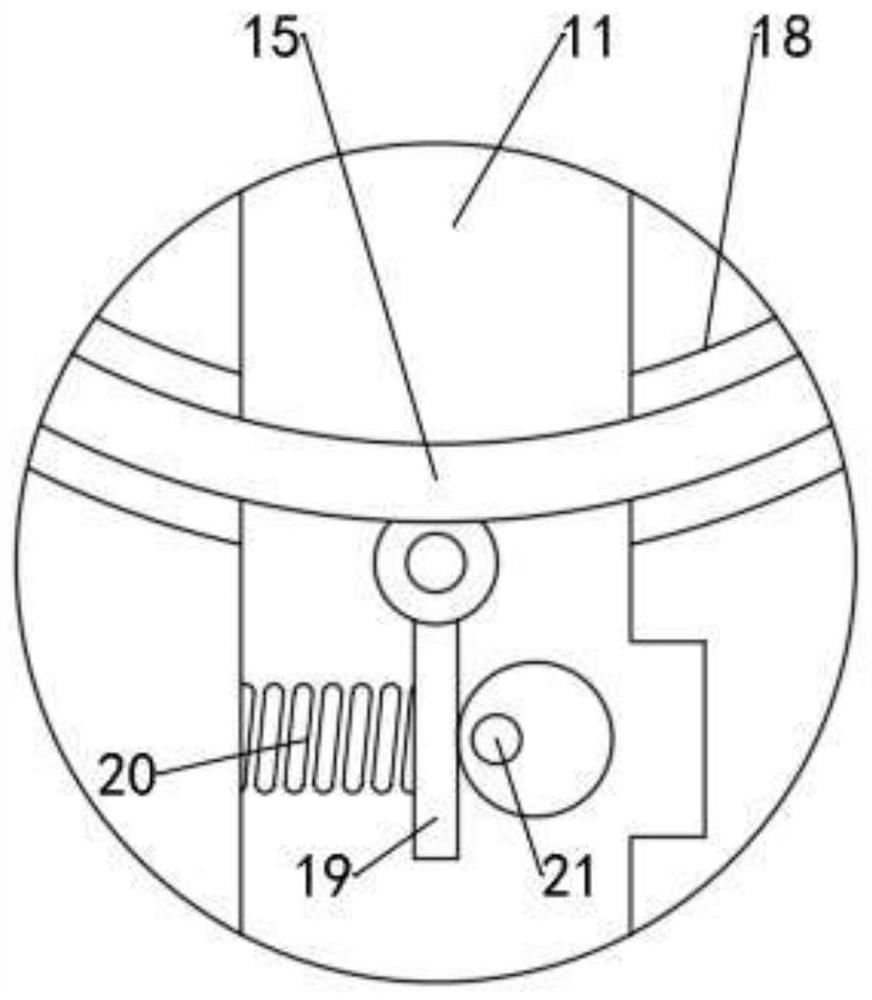

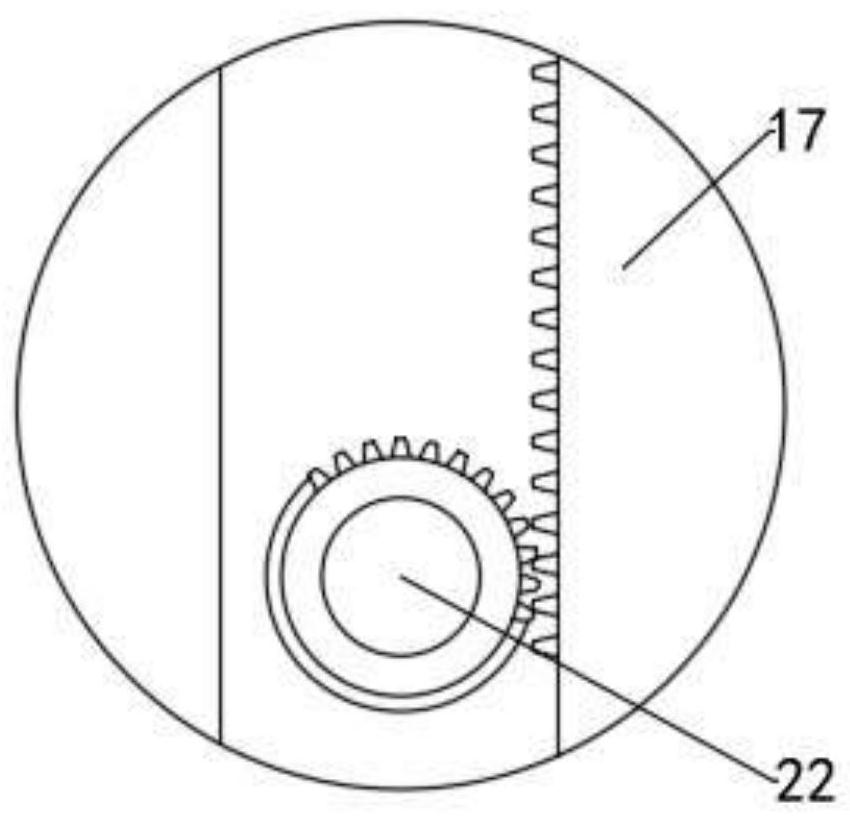

[0023] see Figure 1-4 , a stirring device for desulfurization and denitrification, comprising a base 1, the upper end of the base 1 is equipped with a base 24, a stirring chamber 5 is movably installed on the base 24, and an inverted cone-shaped feeding hopper 6 is arranged at the upper end of the stirring chamber 5 , the hopper 6 is equipped with a cover plate, a discharge pipe 23 is installed on one side of the mixing chamber 5, and a control valve is installed on the discharge pipe 23; A vertical stirring shaft 11 is installed in the chamber 12, and one end of the stirring shaft 11 is connected with a motor, and the end of the stirring shaft 11 away from the drive chamber 12 extends into the stirring chamber 5 and a base plate 13 is mounted on it for rotation, and the base plate 13 is uniformly equipped with A plurality of arc-shaped stirring blades 14; the stirring shaft 11 is provided with an arc-shaped sliding chamber 18, and the lower end of the base plate 13 is provid...

Embodiment 2

[0032] In order to improve the mixing effect of the materials in the mixing chamber 5, this embodiment is improved on the basis of Embodiment 1. The improvement is: an insulation layer is provided inside the stirring chamber 5 to maintain the materials in the stirring chamber 5. In a suitable temperature range, the stirring and mixing effect of materials is promoted, which is convenient for subsequent desulfurization and denitrification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com