Variable flow type ejector for fuel cell based on electromagnetic control valve

An electromagnetic control valve, fuel cell technology, applied in fuel cells, electrochemical generators, circuits, etc., can solve the problems of difficult to achieve sealing, limited ejection performance, difficult to adapt to the needs of hydrogen circulation, etc., to achieve automatic adjustment, Achieving the effect of work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in more detail below in conjunction with accompanying drawing example:

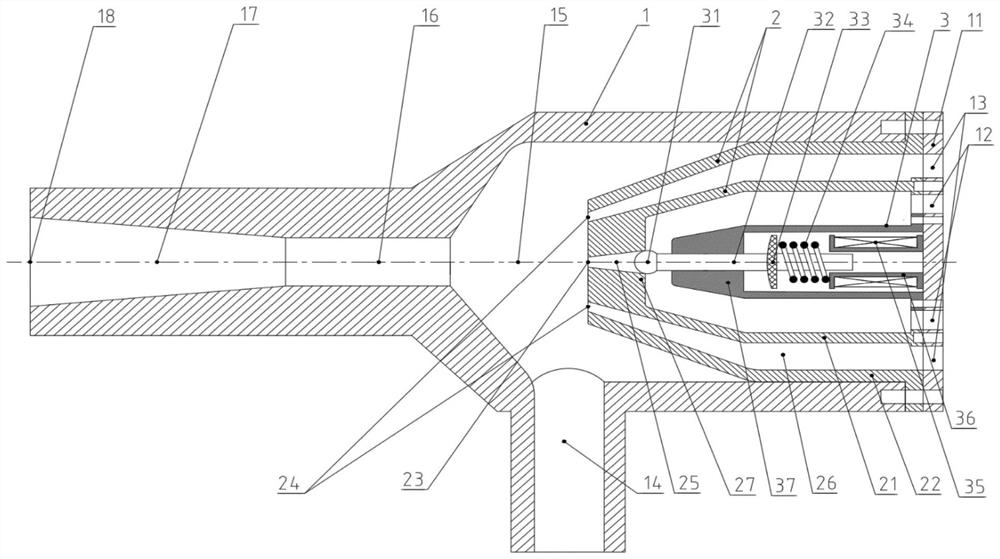

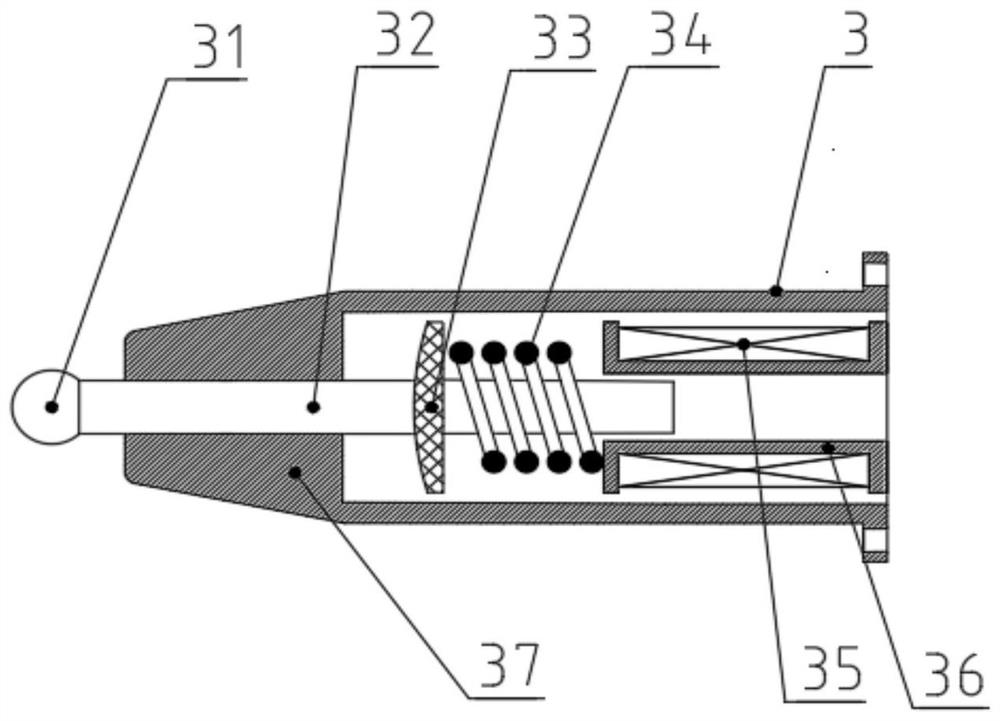

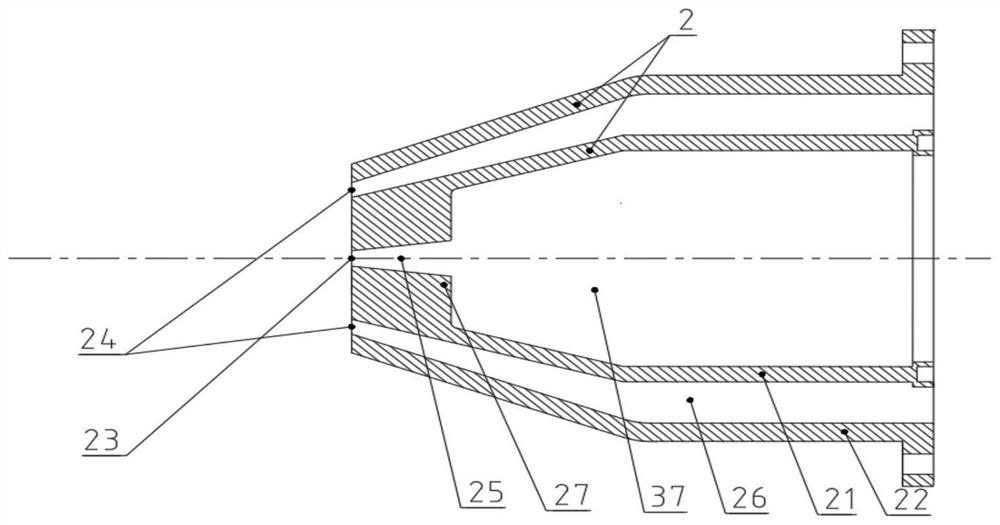

[0022] combine Figure 1-5 , The present invention includes: ejector main body 1, annular main and auxiliary nozzle main body 2, main airway electromagnetic control valve 3.

[0023] The ejector body 1 includes an ejector end cover 11, a first-level inlet 12 of the ejected jet, a second-level inlet 13 of the ejected jet, an inlet 14 of the ejected jet, a suction chamber 15, a mixing chamber 16, a diffusion chamber 17 and a mixed gas Outlet 18; inside the injector body 1 from right to left along the axial direction are the injector end cover 11, the first-level inlet 12 of the jet flow, the second-level inlet 13 of the jet flow, the suction chamber 15, the mixing chamber 16, and the diffusion chamber 17. Mixed gas outlet 18. The end cover 11 of the ejector is connected to the right end of the ejector by bolts, and the first-level inlet 12 and the second-level inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com