Boiler chimney capable of preventing smoke exhaust efficiency from being affected by scaling

A chimney and fouling technology, applied in the field of boiler chimney, can solve the problems of fouling on the inner wall of the chimney, affecting the discharge of flue gas, and low frequency of chimney maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

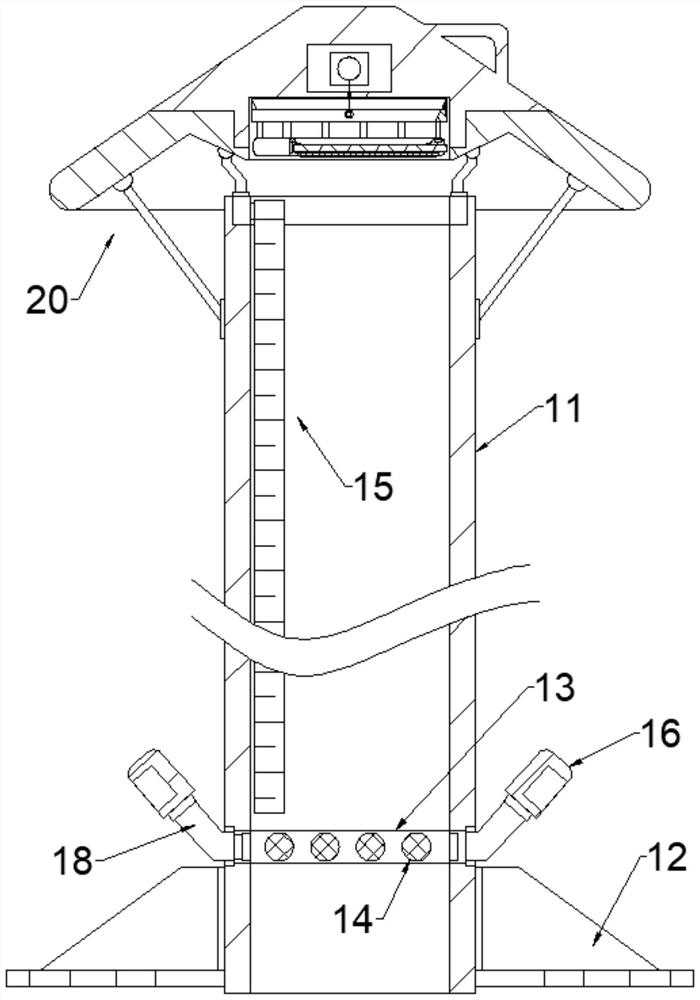

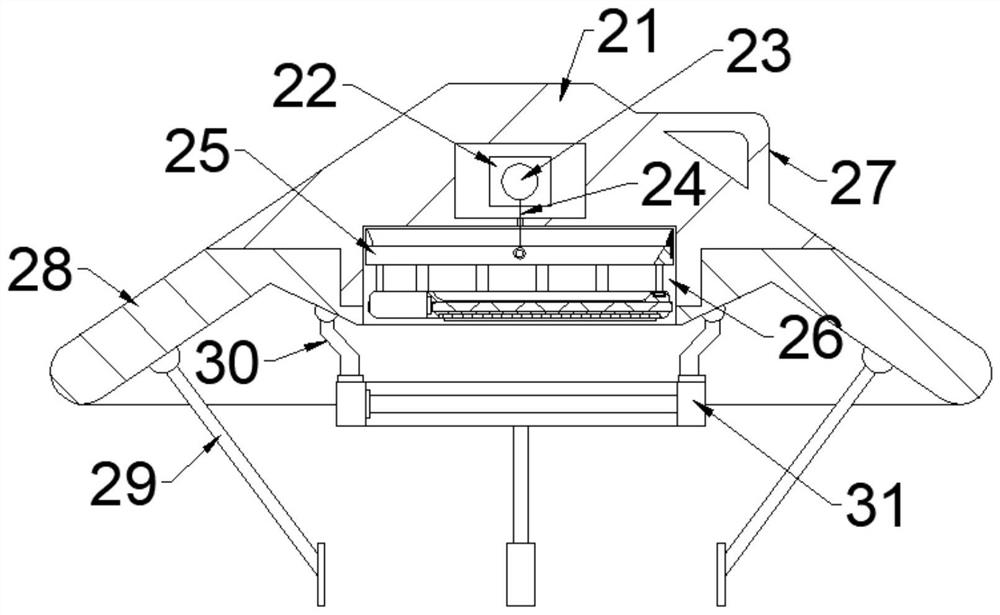

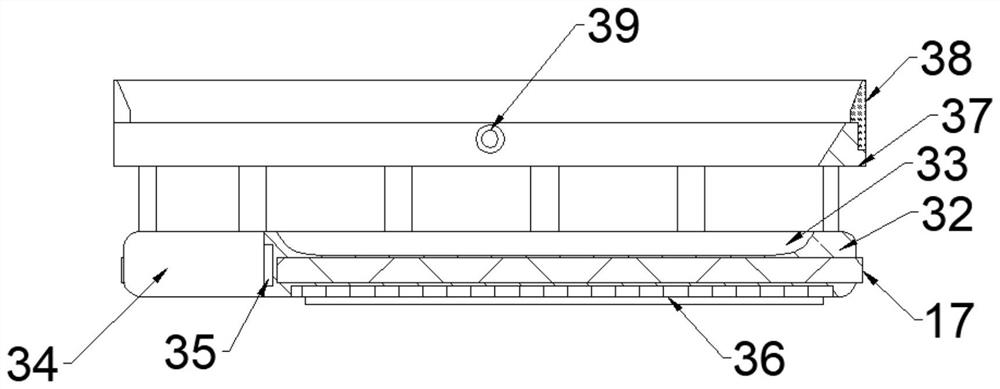

[0025] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0026] A boiler chimney that prevents fouling from affecting the smoke exhaust efficiency described in conjunction with accompanying drawings 1-5 includes a chimney body 11, and a protective exhaust ring 13 is installed on the inner wall of the chimney body 11, and the protective exhaust ring 13 is arranged in an array There is a smoke exhaust hole 14, and the smoke exhaust hole 14 is connected with a control valve pipe 18, and the control valve pipe 18 is equipped with an exhaust port 16, and the chimney body 11 is equipped with a top protection device 20, and the top protection device 20 Including the installation side shell 28, the installation side shell 28 can be disassembled and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com