Fuel oil high-temperature vaporization oil supply system of fuel oil engine

A fuel engine and fuel supply system technology, applied in combustion engines, internal combustion piston engines, engine components, etc., can solve the problems of insufficient vaporization, insufficient vaporization time, and incomplete combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

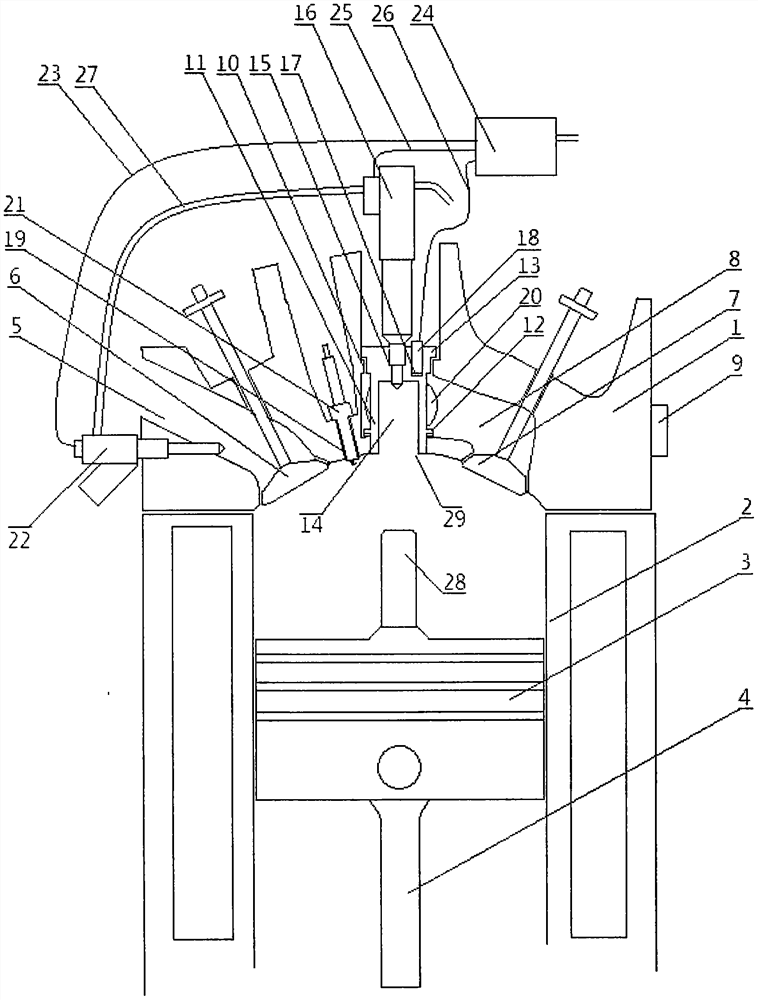

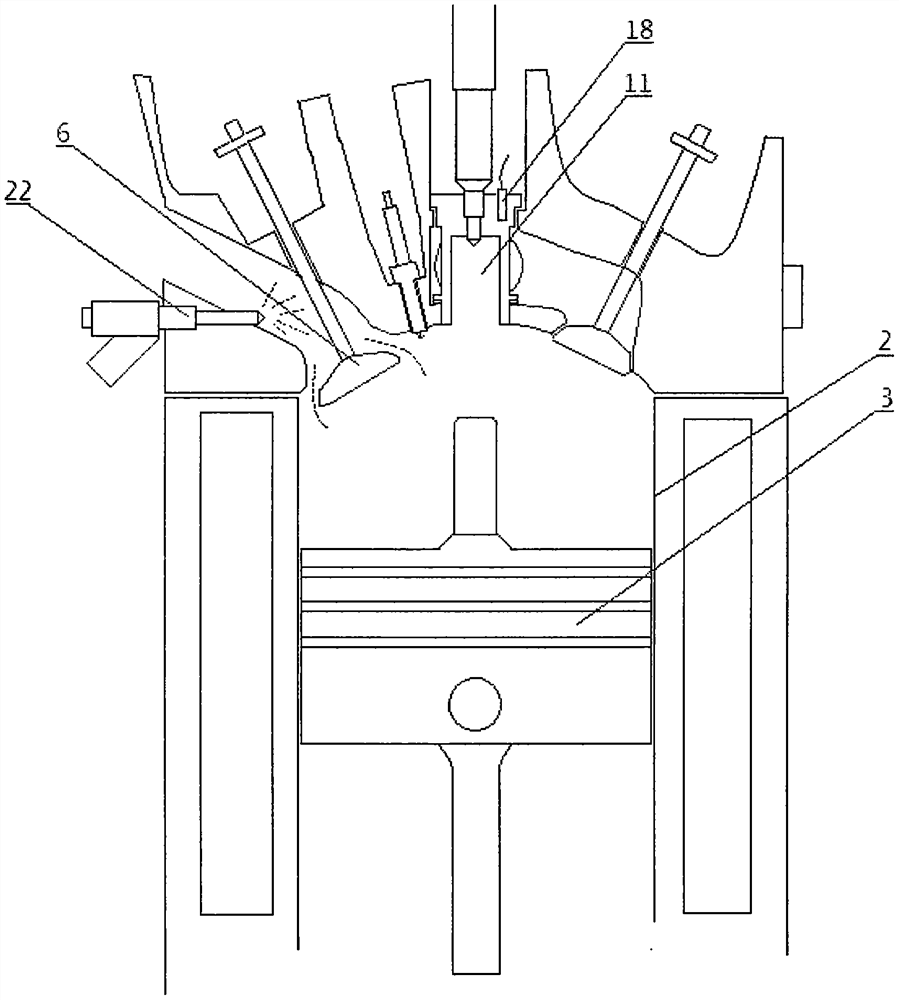

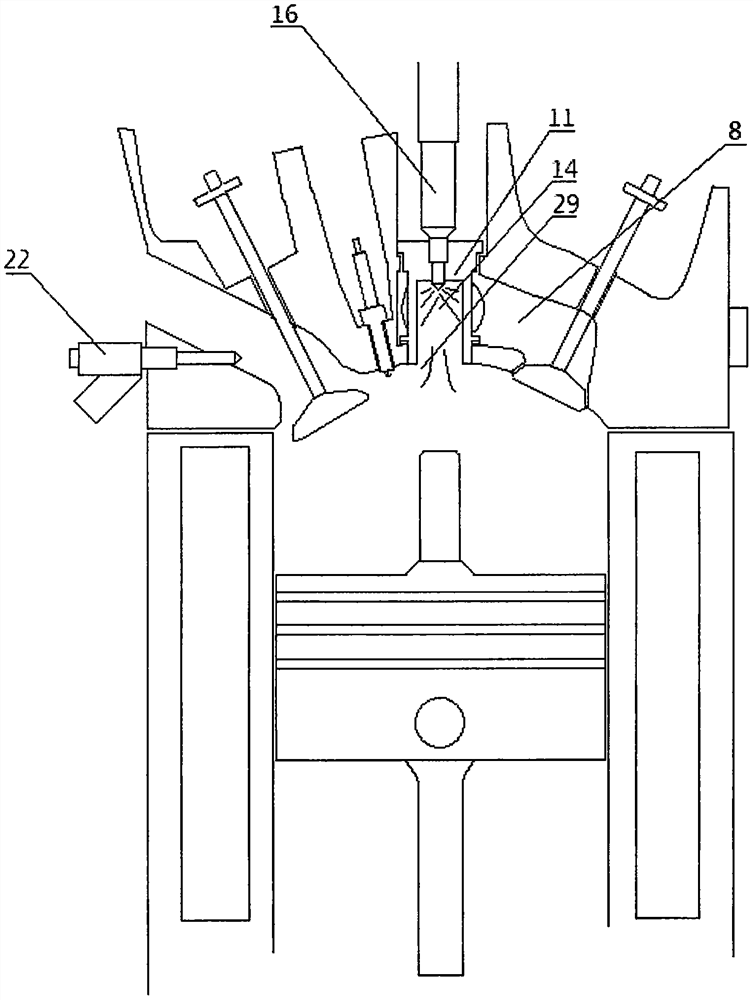

[0011] pass figure 1 It can be seen that the cylinder head (1) is installed on the top of the cylinder (2), and a piston (3) is arranged in the cylinder. When the engine is working, the crankshaft and the connecting rod (4) drive the piston to move up and down in the cylinder to perform suction, During the working strokes of compression, work, and exhaust, the air enters the cylinder through the intake port (5) and the intake valve (6), and the exhaust gas after combustion enters the exhaust port (8) through the exhaust valve (7) and is exhausted. The central position of the cylinder head (1) is provided with an evaporation chamber installation hole (10), the upper end of the evaporation chamber installation hole is installed with a high-temperature evaporation chamber (11), and the lower end of the high-temperature evaporation chamber is sealed under the evaporation chamber. The head (12) is sealed with the installation hole (10) of the evaporation chamber, and the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com