Preparation and application of degradable, biocompatible, high-strength chitin hydrogel

A biocompatible, chitin technology, applied in non-active ingredients medical preparations, drug combinations, tissue regeneration, etc. Compatibility and other issues, to achieve the effect of improving mechanical properties, improving mechanical properties, biodegradability and swelling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

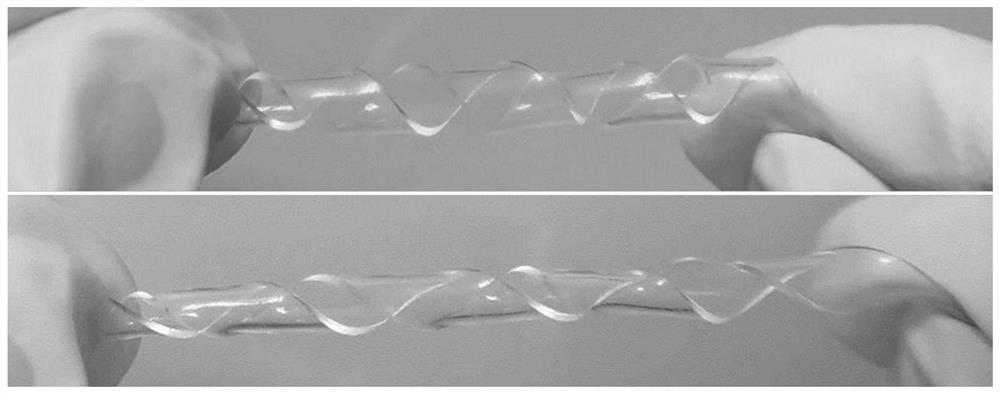

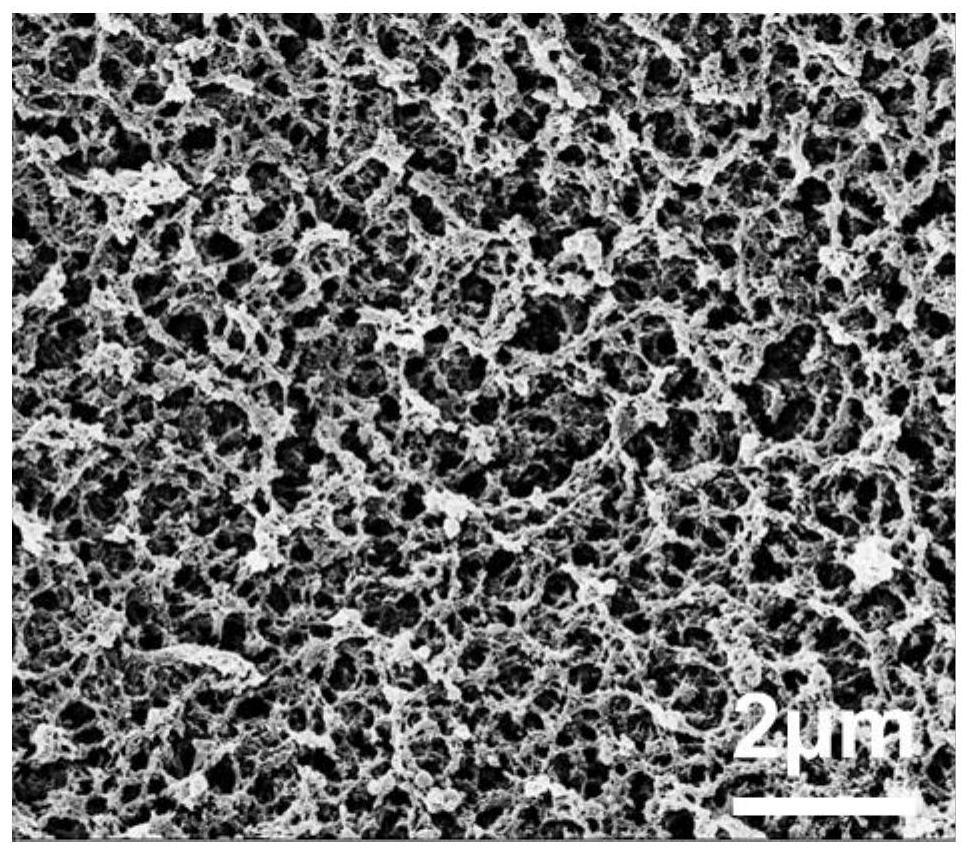

[0034] Use 16% potassium hydroxide / 4% urea to dissolve chitin to prepare a chitin solution with a concentration of 5%, and add the silane coupling agent KH550 dropwise at 0°C (mass ratio of KH550 to chitin solution=3:100) and stirred at a speed of 700rpm for 1h, and after centrifugal defoaming, the chemically crosslinked chitin gel was obtained by casting method, and then the gel was transferred to an ethanol coagulation bath with a concentration of 95% and a temperature of 4°C for physical crosslinking for 8h. Finally, the hydrogel obtained by washing with water until neutral has certain light transmittance, high strength and high toughness, biodegradability and biocompatibility.

Embodiment 2

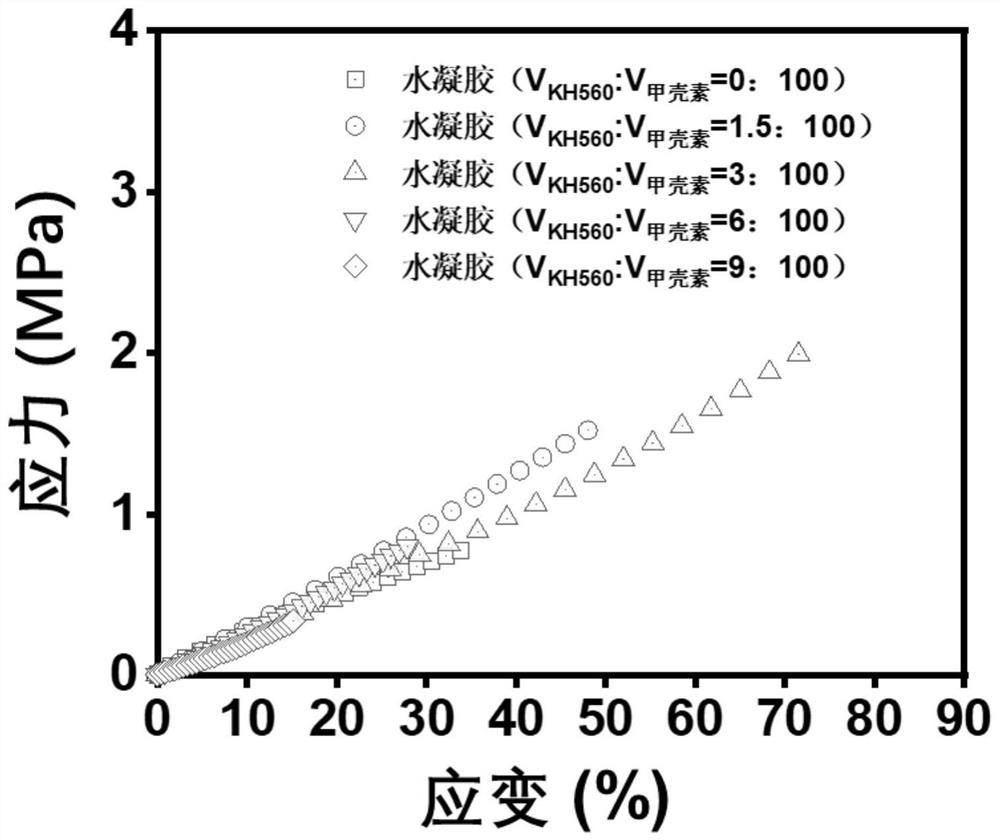

[0036] Use 16% potassium hydroxide / 4% urea to dissolve chitin to prepare a chitin solution with a concentration of 5%, and add the silane coupling agent KH560 dropwise at 0°C (mass ratio of KH560 to chitin solution=3:100) and stirred at a speed of 700rpm for 1h, and after centrifugal defoaming, the chemically crosslinked chitin gel was obtained by casting method, and then the gel was transferred to an ethanol coagulation bath with a concentration of 95% and a temperature of 4°C for physical crosslinking for 8h. Finally, the hydrogel obtained by washing with water until neutral has certain light transmittance, high strength and high toughness, biodegradability and biocompatibility.

Embodiment 3

[0038] Use 16% potassium hydroxide / 4% urea to dissolve chitin to prepare a chitin solution with a concentration of 5%, and add the silane coupling agent KH560 dropwise at 0°C (mass ratio of KH560 to chitin solution=3:100) and stirred at a speed of 700rpm for 1h, and after centrifugal defoaming, the chemically crosslinked chitin gel was obtained by casting method, and then the gel was transferred to an ethanol coagulation bath with a concentration of 95% and a temperature of 4°C for physical crosslinking for 8h. Finally, the hydrogel obtained by washing to neutrality has certain high light transmittance, high strength and high toughness, biodegradability and biocompatibility.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com