Press machine

A mechanical and hydraulic cylinder technology, applied in the field of high-speed stamping machinery, can solve the problems of unrealistic, unrecorded slider position control, inability to make the piston move forward and backward at high speed, and achieve the effect of less swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

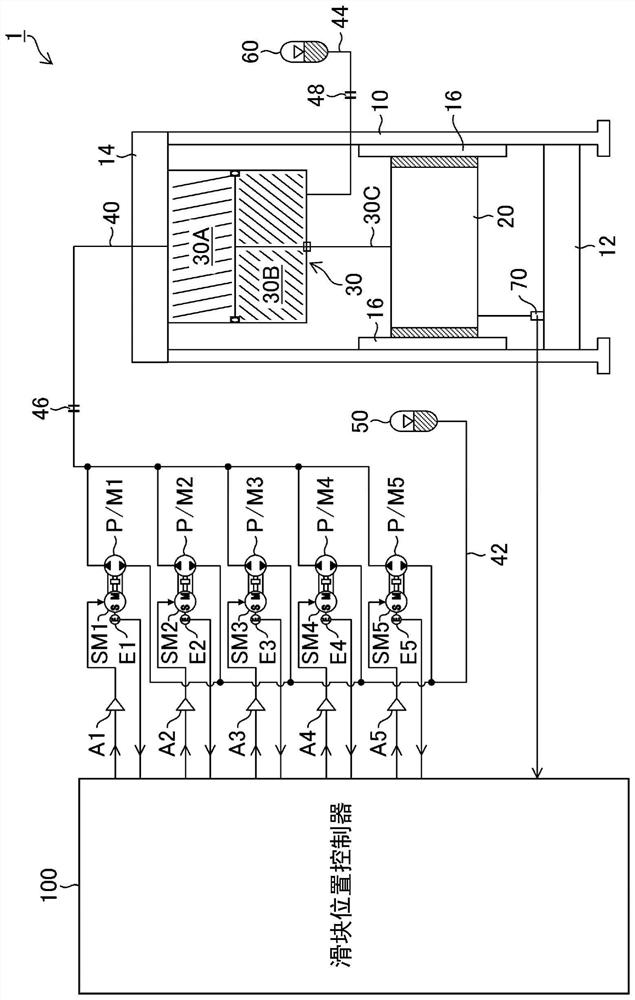

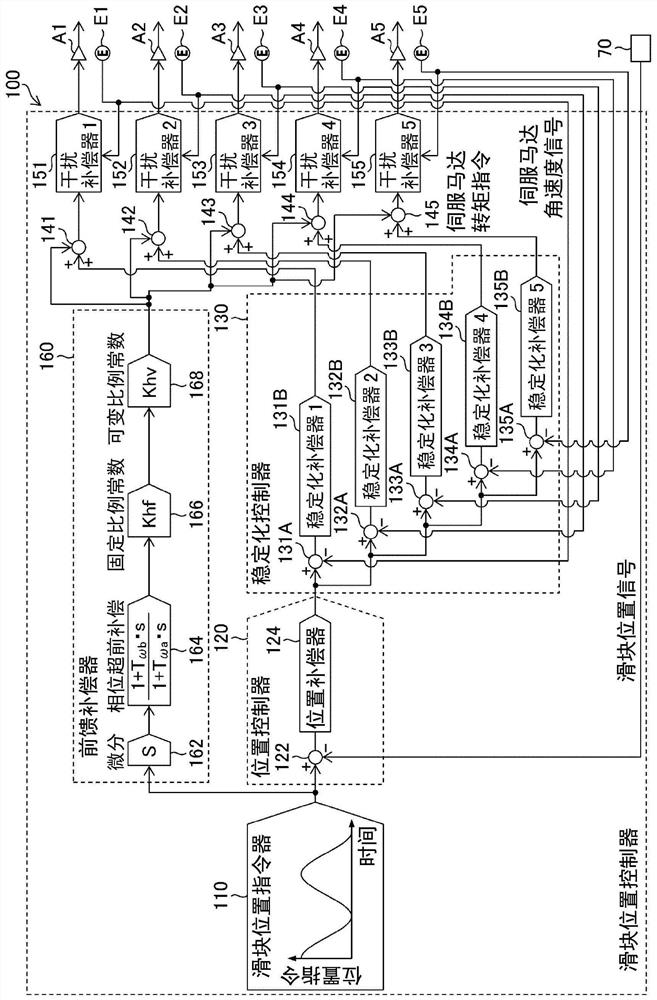

[0078] figure 1 It is a figure which shows 1st Embodiment of the press machine of this invention.

[0079] figure 1 The press machine 1 of the first embodiment shown has a frame composed of a column 10, a base 12, and a crown (frame upper strength member) 14, and the guide 16 provided on the column 10 is used to move the slider 20 in the vertical direction (lead Vertical direction) to guide the way to move freely.

[0080] A hydraulic cylinder (hydraulic cylinder) 30 for driving the slider 20 is fixed to the crown 14 , and a piston rod 30C of the hydraulic cylinder 30 is connected to the slider 20 .

[0081] As the hydraulic device for driving the hydraulic cylinder 30, a plurality of hydraulic pumps / motors (in this example, 5 hydraulic pumps / motors (P / M1 to P / M5)) are provided, and each hydraulic pump / motor A plurality of servomotors (in this example, five servomotors (SM1 to SM5)) are axially connected to the rotation axes of (P / M1 to P / M5).

[0082] One port (first port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com