Vertical cavity surface emitting laser based on van der Waals epitaxy and its fabrication method

A technology of vertical cavity surface emission and fabrication method, which is applied in the field of vertical cavity surface emitting laser and its fabrication, can solve the problems of complicated process and partial destruction of the active area, and achieves the advantages of simple process, reduced threshold current and improved crystal quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

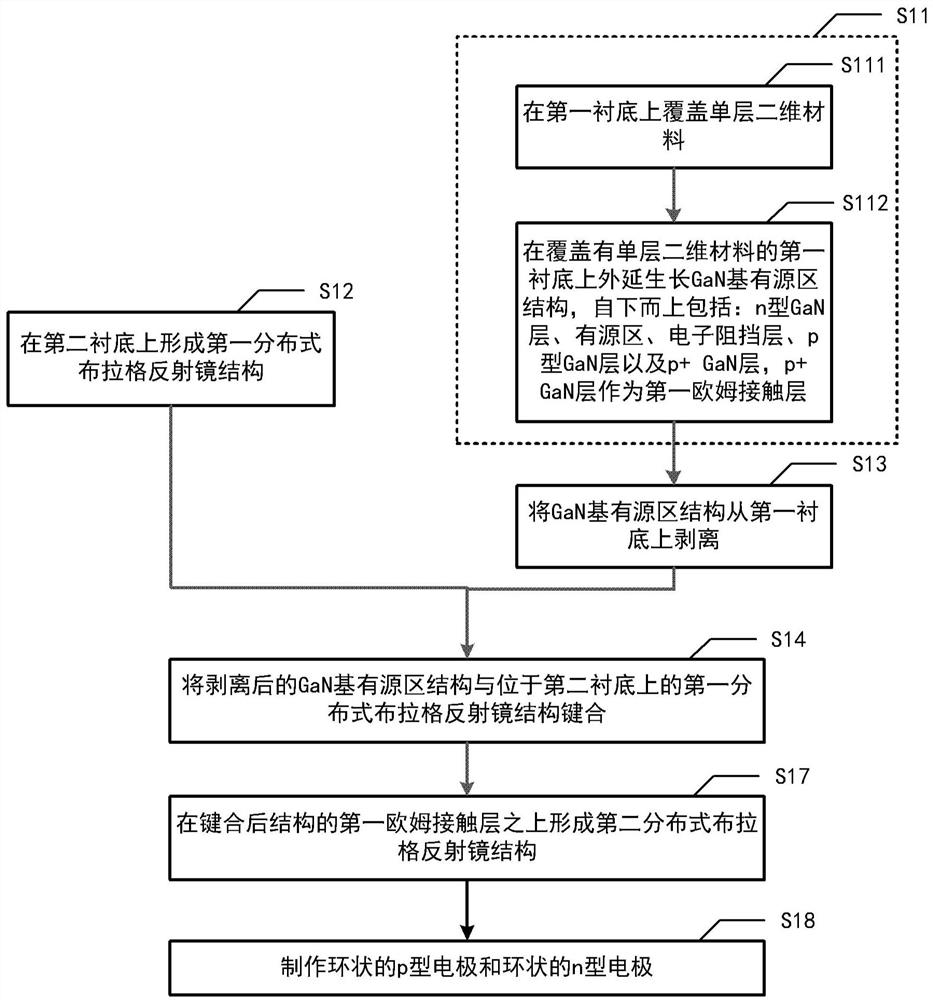

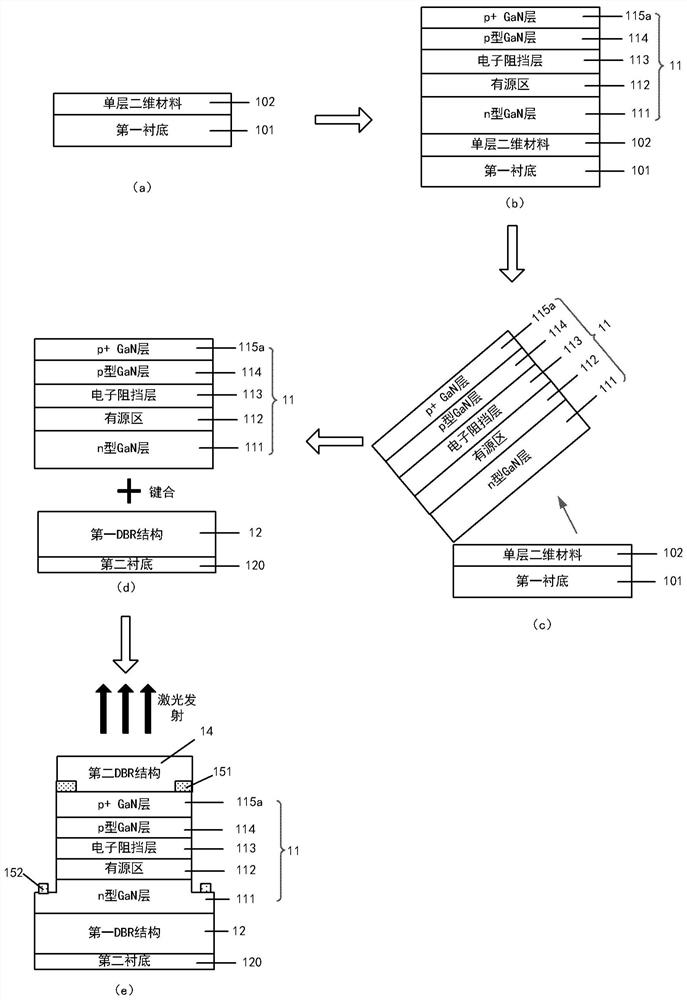

[0057] Embodiments of the present disclosure provide a van der Waals epitaxy-based vertical cavity surface-emitting laser and a fabrication method thereof, in which a GaN-based active region structure is epitaxially grown on a first substrate covered with a single-layer two-dimensional material, based on a single-layer The arrangement of two-dimensional materials can bond the GaN-based active region structure with the first distributed Bragg reflector structure on the second substrate after peeling off the first substrate, which greatly reduces the impact on the GaN-based active region. The structure is destroyed, thereby improving the crystal quality of the active region, reducing the threshold current, and obtaining a higher-quality GaN-based VCSEL. At the same time, the method of growing the active region structure by van der Waals epitaxy and then transferring it will not cause damage to the first substrate. Theoretically, the infinite reuse of the first substrate can be re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com