Production equipment and process of zirconium sponge

A production equipment and technology of zirconium sponge, applied in the field of production equipment and technology of zirconium sponge, can solve the problems of poor reduction reaction efficiency, low reduction reaction efficiency of zirconium sponge, waste of zirconium tetrachloride, etc. Economic and social benefits, and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

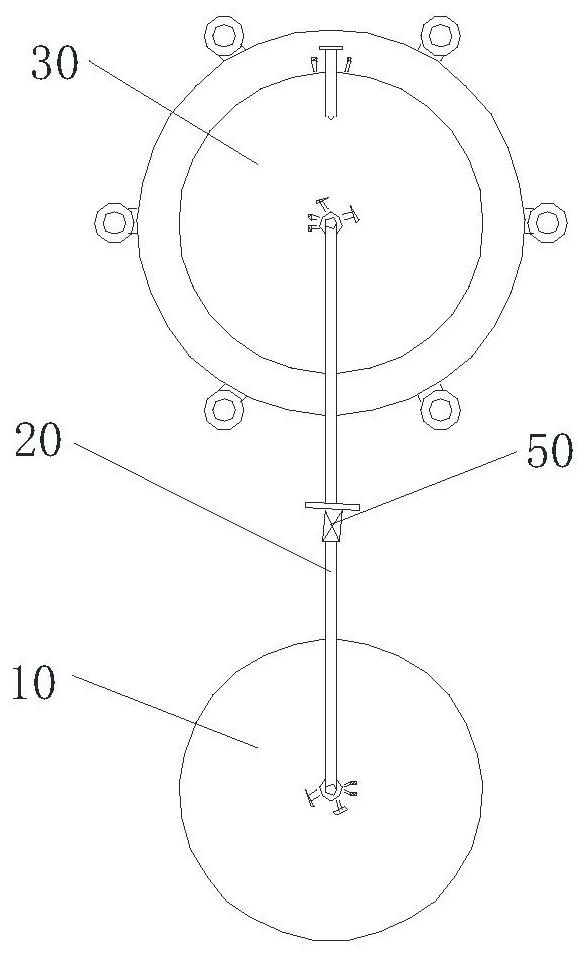

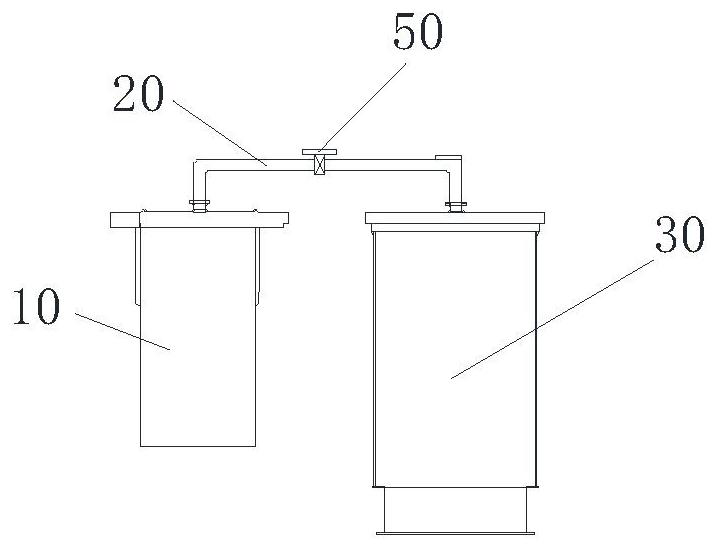

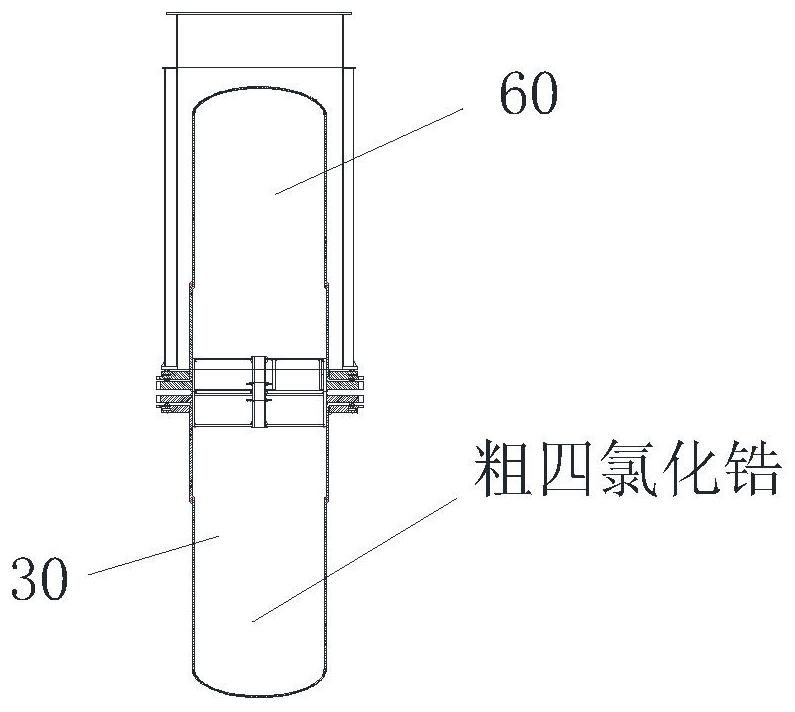

[0039] like Figure 1-2 As shown, a production equipment for zirconium sponge is provided in this embodiment, including a sublimation furnace 30 and a first reduction furnace 10 with a channel 20 on the top, and the channel 20 provided on the top connects the sublimation furnace 30 and the first reduction furnace 10 to each other In order to be able to adjust and control the intake of gaseous zirconium tetrachloride at any time, a first check valve 50 is provided on the channel 20, and the sublimation furnace 30 can heat and purify the zirconium tetrachloride therein, and the purified tetrachloride Zirconium oxide is in a gaseous state, and metallic magnesium in the first reduction furnace 10 is heated to a liquid state. like image 3 and 4 As shown, zirconium tetrachloride is purified in the sublimation furnace 30. One way is to set a condensation furnace 60 above the sublimation furnace 30 to purify the crude zirconium tetrachloride into high-purity zirconium tetrachloride...

Embodiment 2

[0049] This embodiment has been further improved on the basis of Embodiment 1, the difference is: as Image 6 As shown, in the production equipment for zirconium sponge provided in this embodiment, a trachea branch is provided between the intake pipe 107 and the second check valve 108, and a third check valve 117 and an explosive body 118 are provided on the trachea branch. There are several explosive bodies 118 stored in the storage box 116, and the air pump 109 first utilizes the negative pressure to suck the explosive bodies 118 into the branch circuit, and then uses the positive pressure generated to press the explosive bodies 118 into the intake pipe 107 And in the gas explosion tube 104, the explosive body 118 is ejected from the bottom of the gas explosion tube 104 by the pressure of argon and explodes in the magnesium liquid in the furnace 115. In this example, if Figure 7 As shown, the explosive body 118 is set to a spherical structure, the outer shell of the explos...

Embodiment 3

[0057] On the basis of Embodiment 1 and 2, further improvement has been carried out in this embodiment, the difference is: as Figure 8 and 9 As shown, a first reduction furnace 10 and a second reduction furnace 40 are connected with a sublimation furnace 30 through a channel 20. The first reduction furnace 10 and the second reduction furnace 40 have the same structure, and this structure expands the production capacity. times, if the consumption of 2400kg of zirconium tetrachloride requires two furnaces to react 1200kg of zirconium tetrachloride and 400kg of magnesium, the total deliquescence of about 200kg of zirconium tetrachloride is calculated, and the sublimation furnace with 2400kg of zirconium tetrachloride is connected Two reduction furnaces with 400kg of liquid magnesium, the deliquescence is reduced to 100kg, which is the same as the waste of 1200kg of zirconium tetrachloride, which saves raw materials; compared with the single consumption of 1200kg of zirconium tet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com