Microbial fly ash building material and preparation method thereof

A technology of microorganisms and fly ash, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of high processing costs of melting and solidification technology, inability to consume fly ash on a large scale, and small total amount of fly ash, etc. Achieve significant environmental and social benefits, good practical application value, and reduce the effect of leaching of harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

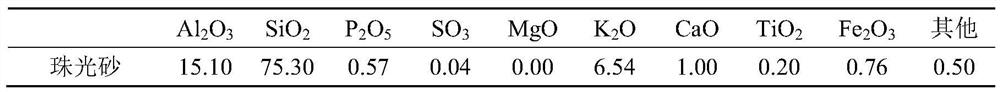

[0048] Fifty -as -as -as -as -on -as -as -as -as -as -greeted, 2 copies of silicon powder, 30 copies of ash, 3 copies, 15 copies of cement, 10 cooked lime, 10 copies of 50-80 mesh beads, 10 copies of bacteria, 2 copies of pure meal, 5 copies of red mud, 5 copies of red mud , 9 parts of steel slag powder, 1 portion of Grade A grade, 0.05 polyacrylamide, and 0.1 copies of KH570 Silicane Puppets.

[0049] The bacterial liquid is screened, activated, and cultured the bacteria of the microbial KJ01.

[0050] The prepared grain crushing index was 26 %, the water absorption rate was 1.7 %, and the quality loss corresponding to the solid indicator was 12.5 %.

Embodiment 2

[0052] 70 flying ash, 10 silicon powder, 20 copies of ash, 5 copies, 10 copies of cement, 10 copies of lime, 30 copies of 50-80 mesh beads, 40 bacteria liquids, 4 copies of pure meal emulsion, 8 copies of red mud, 8 copies of red mud , 7 parts of steel slag powder, 20 parts of nutrient solution, 0.5 copies of Grade A grade Grade, 0.2 copies of polyacrylamide, and 0.5 copies of KH570 Silicane puppets.

[0053] The bacterial liquid is screened, activated, and cultured the bacteria of the microbial KJ01.

[0054] The prepared grain crushing indicators were 19 %, the water absorption rate was 1.9 %, and the quality loss corresponding to the solid indicator was 7.6 %.

Embodiment 3

[0056] Fifty -asylum, 2 parts of silicon powder, 25 parts of silicon powder, 25 copies, 3 copies of cement, 15 copies of lime, 10 copies of 50-80 mesh beads, 10 copies of bacteria, 2 copies of pure meal, 6 copies of red mud, 6 copies of red mud , 8 parts of steel slag, 10 parts of nutrient solution, 0.8 copies of Grade A grade Grade, 0.1 copies of polyacrylamide, and 0.1 copies of KH570 Silicane puppets.

[0057] The bacterial liquid is screened, activated, and cultured the bacterial liquid.

[0058] The prepared grain crushing index is 14 %, the water absorption rate is 1.2 %, and the quality loss corresponding to the solid indicator is 5.4 %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com