Mining belt conveyor with automatic adjusting function and based on Internet-of-Things technology

An Internet of Things technology and automatic adjustment technology, which is applied in the field of mining belt conveyors, can solve problems such as the inability to adjust the angle of mining belt conveyors, and achieve the goals of avoiding damage to health, prolonging service life, and improving stability and balance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

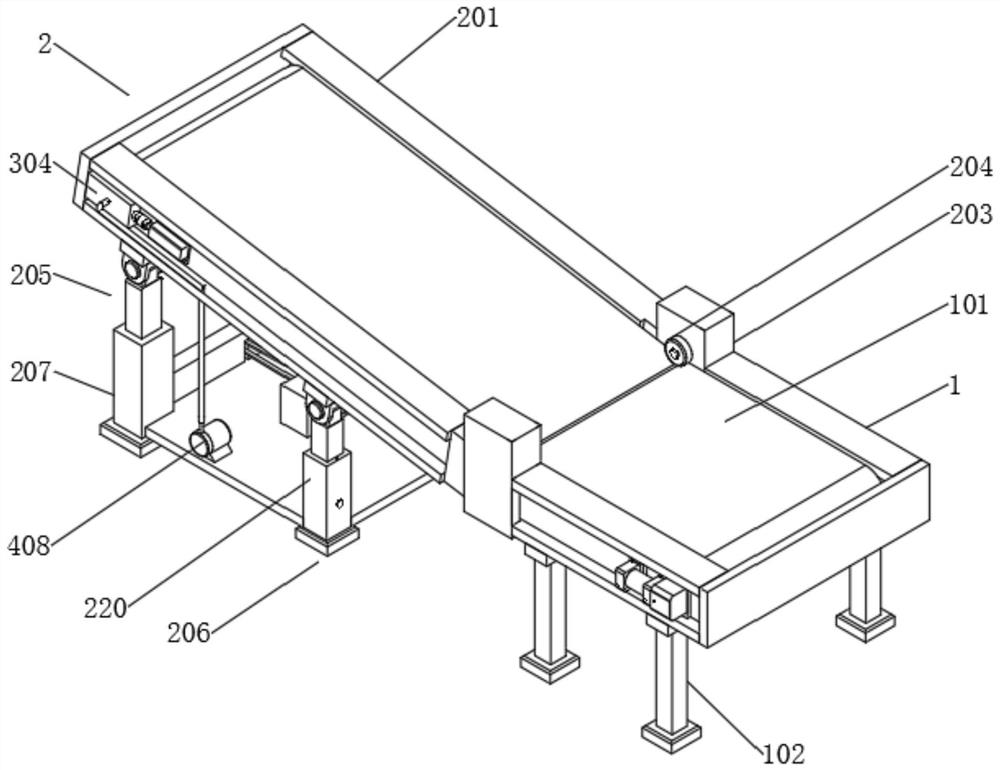

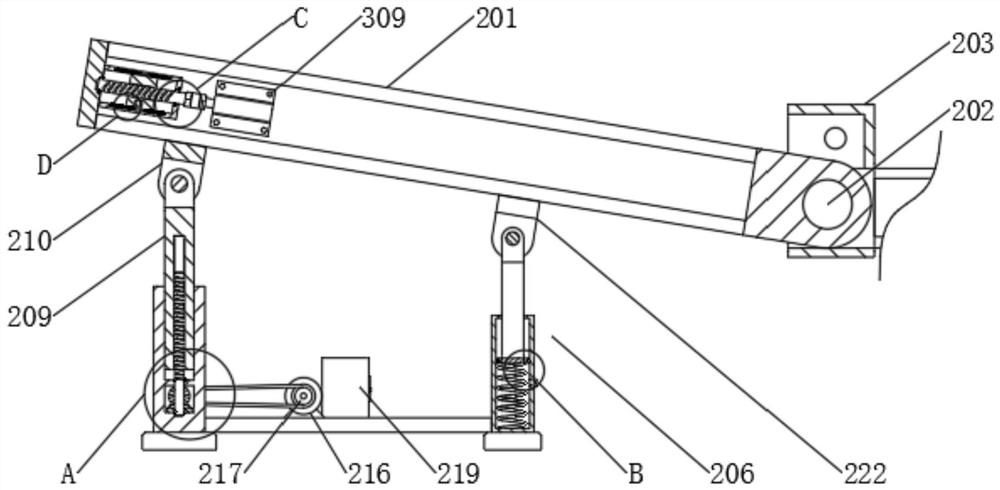

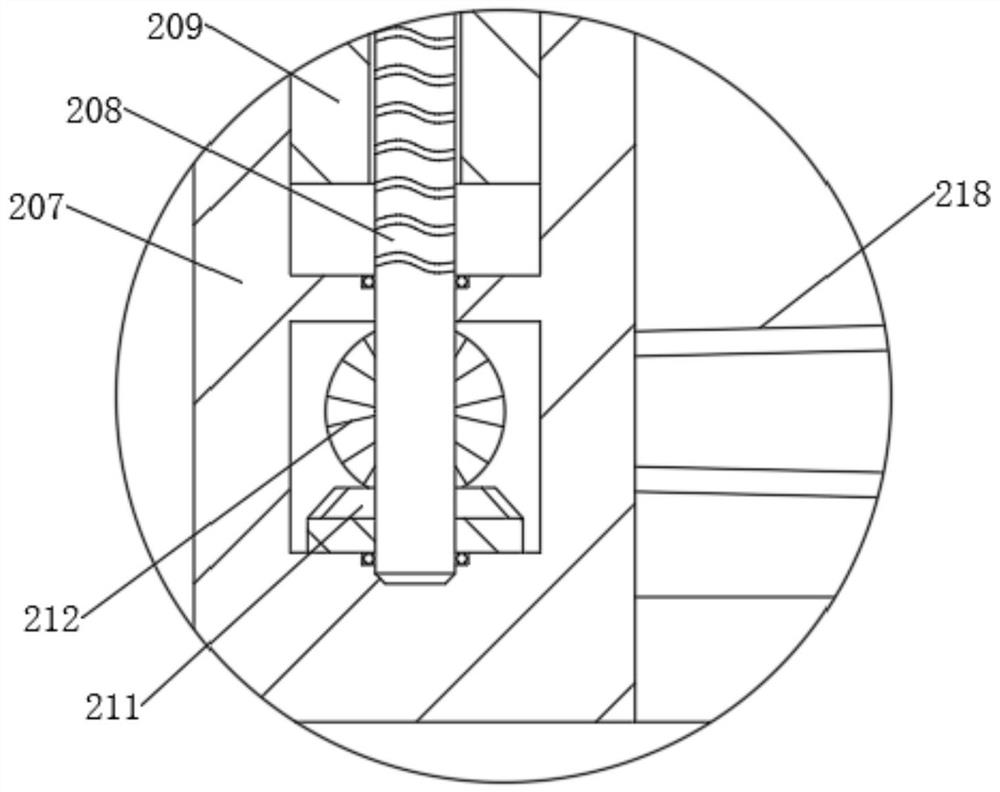

[0033] The invention discloses a mining belt conveyor with automatic adjustment function based on Internet of Things technology. Figure 1-Figure 10 As shown, the belt conveyor body 1 is included, and the belt conveyor body 1 is provided with a conveying belt 101, which is convenient to transport the material through the movement of the conveying belt 101. The side of the belt conveyor body 1 away from the conveying belt 101 is connected with multiple The supporting legs 102 are convenient to play the role of fixed support to the belt conveyor body 1. The end of the conveyor belt 101 away from the belt conveyor body 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com