Preparation method of mobile phone middle plate jig

A fixture and mobile phone technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of low efficiency and high cost, achieve good fluidity, reduce pores, and avoid the effect of body collapse or deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

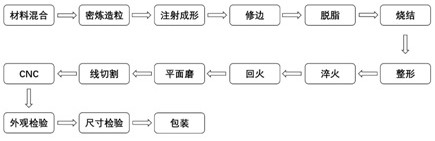

[0045] Please refer to Figure 1 to Figure 4 As shown, it shows the specific structure of a preferred embodiment of the present invention, which is a manufacturing process for the middle plate jig of a mobile phone based on metal powder injection molding, including the following steps:

[0046] Metal powder selection: choose the SUS420 gas-atomized alloy powder produced by Huzhou Huijin Material Technology Co., Ltd. and the SUS420 water-atomized alloy powder produced by Hunan Hengji Powder Technology Co., Ltd. Mixing ratio 4:6, the specific information of the gas atomization and water atomization powder is as follows:

[0047]

[0048] The binder is weighed: the binder is mainly composed of polyoxymethylene 7520, polyethylene 6098, high-density polyethylene 7200, Brazilian wax T3, and sliced paraffin. 0.5 allocation, each of the binders is weighed separately and placed in full bloom. Each of the binders used in the present invention and the manufacturer are: polyoxymethy...

Embodiment 2

[0061] Embodiment 2: The similarities between this embodiment and Embodiment 1 will not be repeated, and the difference is:

[0062] According to the preparation method in Example 1, select the SUS420 gas-atomized alloy powder produced by Huzhou Huijin Material Technology Co., Ltd. and the SUS420 water-atomized alloy powder produced by Hunan Hengji Powder Technology Co., Ltd., and mix them according to the mass ratio of 5:5 , the mixing method and subsequent process conditions are carried out in strict accordance with Example 1 to obtain the final product, and the test data are shown in Table 5.

Embodiment 3

[0063] Embodiment 3: The similarities between this embodiment and Embodiment 1 will not be repeated, and the difference is:

[0064] According to the preparation method in Example 1, select the SUS420 gas-atomized alloy powder produced by Huzhou Huijin Material Technology Co., Ltd. and the SUS420 water-atomized alloy powder produced by Hunan Hengji Powder Technology Co., Ltd., and mix them according to the mass ratio of 6:4 , the mixing method and subsequent process conditions are carried out in strict accordance with Example 1 to obtain the final product, and the test data are shown in Table 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com