Digital all-in-one guide plate for odontoless jaw implantation and manufacturing method thereof

A manufacturing method and technology of edentulous jaws, applied in dentistry, dental implants, additive manufacturing, etc., can solve problems such as poor adaptability, achieve the effects of reducing the number of printing times, matching accurately, and avoiding deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

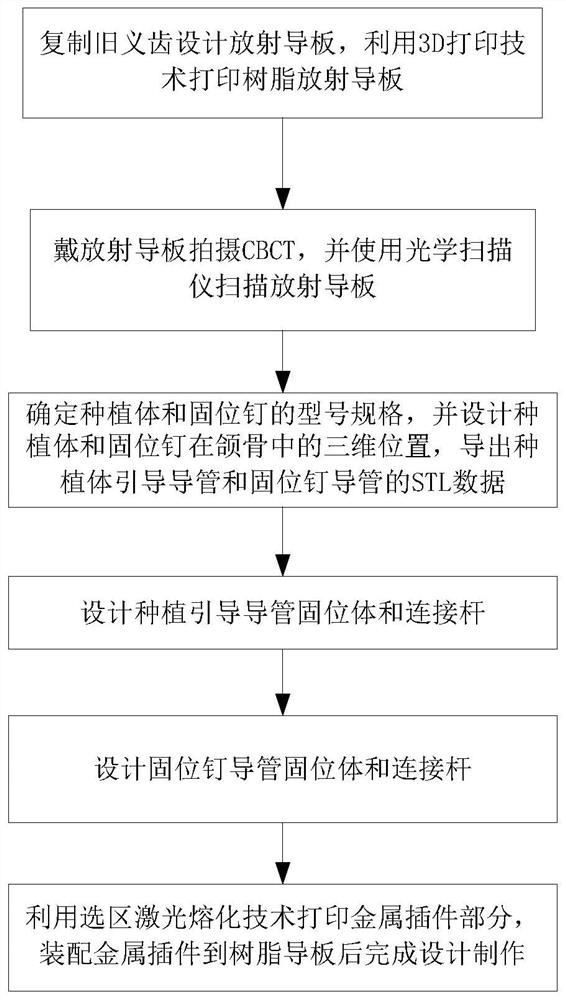

[0043] A method for manufacturing a digital all-in-one guide plate for edentulous implantation, comprising the following steps:

[0044] S1: Obtain a radiation guide plate, the method of obtaining the radiation guide plate is: copy the old denture to design the radiation guide plate, and use 3D printing technology to print the radiation guide plate;

[0045] S2: Wear the radiation guide obtained in step S1 in the oral cavity and use CBCT equipment to scan to obtain the CBCT data of the oral cavity, use an optical scanner to scan the radiation guide to obtain the optical scanning data of the radiation guide, and fit the CBCT data and optical scanning data to obtain the implant data;

[0046] S3: Determine the model specifications of the implant and the retaining screw according to the implant data, and design the three-dimensional position of the implant and the retaining screw in the jaw, and derive the data of the implant guiding guide 7 and the retaining guide 8;

[0047] S...

Embodiment 2

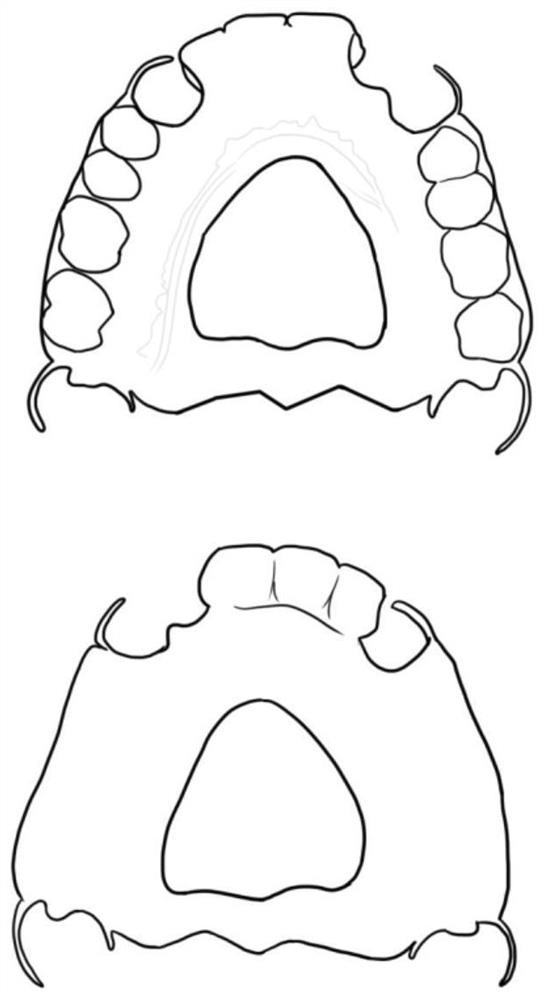

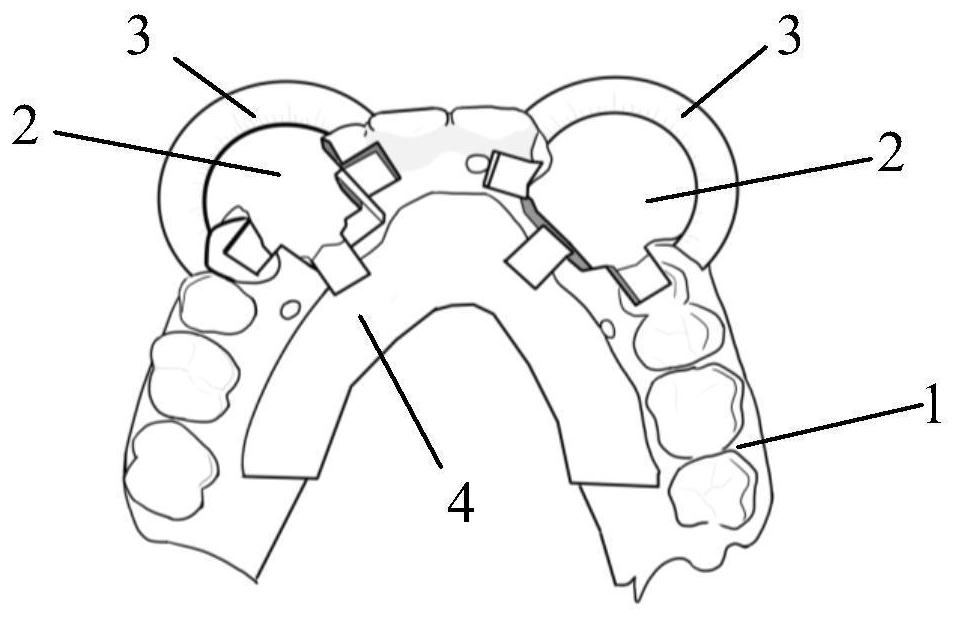

[0057] Such as Figure 7 As shown, the digital all-in-one guide plate for edentulous implantation includes a guide plate main body 1, an implant guide part insert and a retention part insert, and the guide plate main body 1 is respectively connected with the implant guide part insert and the retention part insert .

[0058] The guide plate main body 1 includes a jaw model guide plate, an annular connecting rod 3 and a horseshoe-shaped reinforcing plate 4, two annular connecting rods 3 are arranged on the labial side of the jaw model guide plate, and a The space between the horseshoe-shaped reinforcing plate 4 , the annular connecting rod 3 and the jaw model guide plate is the planting area 2 .

[0059] The insert for the implant guide part includes a guide catheter 7, an arc-shaped retainer 5 and three square retainers 6, and the outer wall of the guide catheter 7 is connected to the arc-shaped retainer 5 and the three square retainers through a connecting rod. body 6, the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com