Lining circular ring assembled by prefabricated segments with corbel connecting bases and assembling method of lining circular ring

A corbel connection and segment assembly technology, applied in shaft lining, tunnel lining, shaft equipment, etc., can solve problems such as difficulty in guaranteeing effectiveness, high construction work intensity, and difficulty in drilling positioning, simplifying the appearance types, eliminating Construction difficulties and the effect of eliminating quality risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

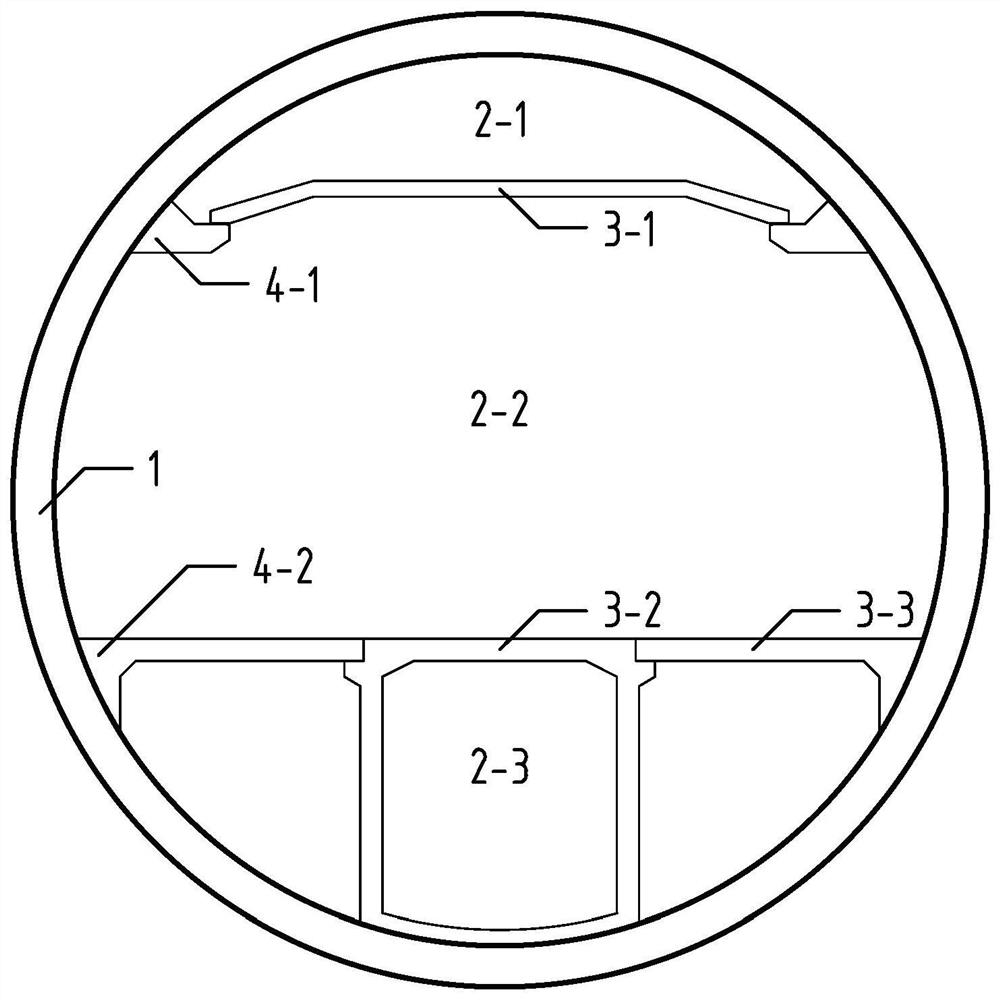

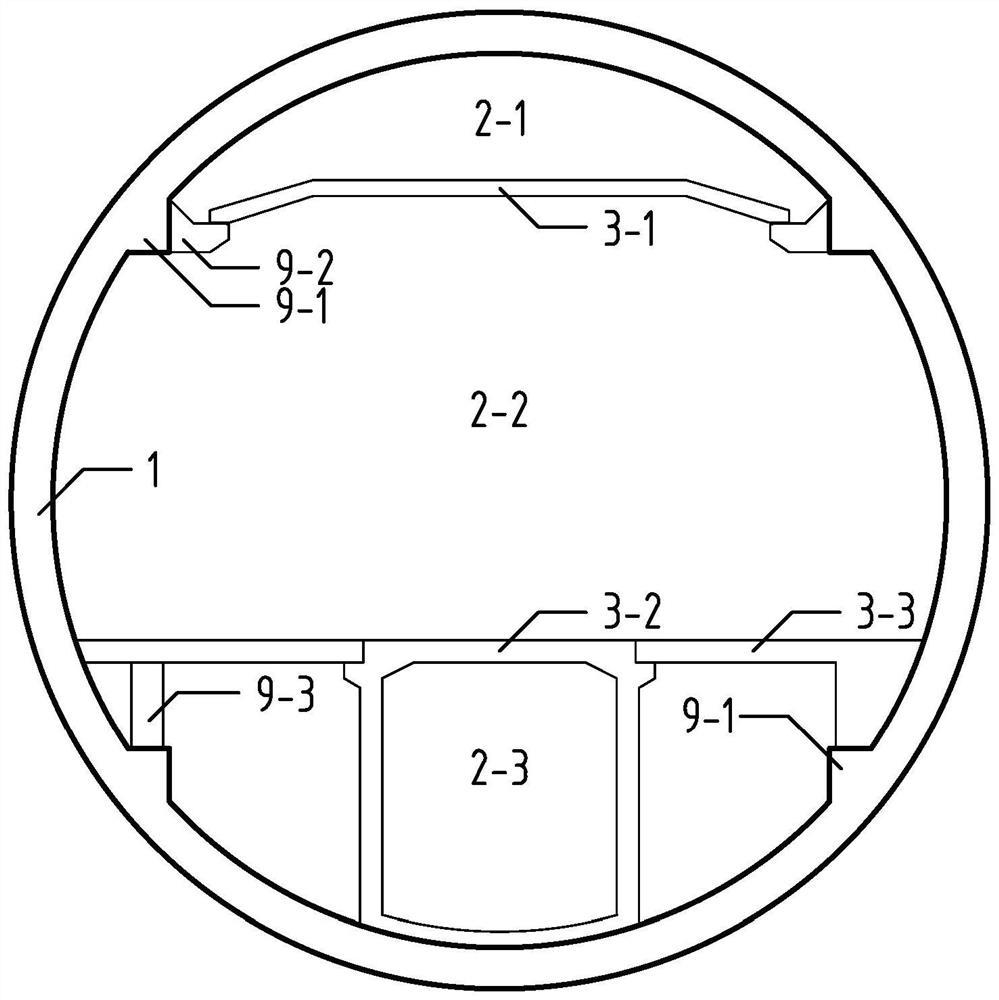

[0109] The shape, structure and assembly method of the prefabricated segment with corbel connection base proposed by the present invention can be applied to the lining structure formed by assembling the prefabricated segments with flue panels, driveway panels or other internal support components. For connection see figure 2 connection structure.

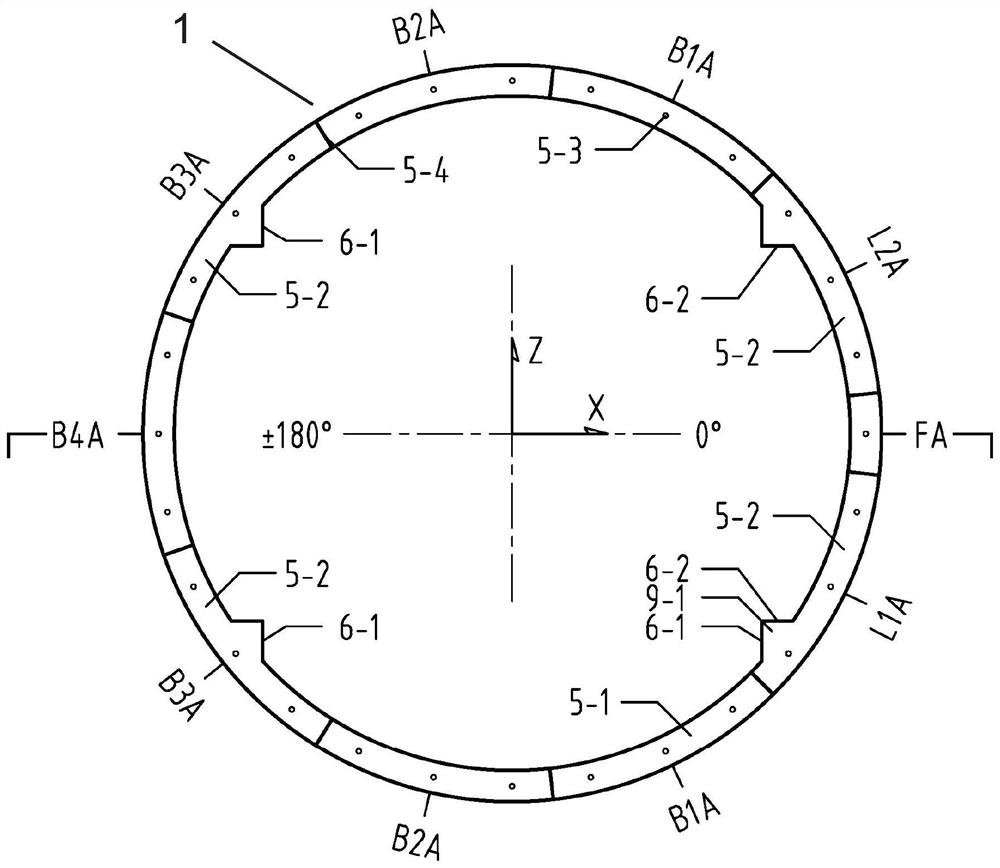

[0110]The above elaboration in conjunction with the accompanying drawings is only one of the application examples enumerated to illustrate the intention, principle and method of the present invention. For example, the lining ring is divided into 10 pieces, which are 7 standard pieces, 2 adjacent pieces and 1 topping piece respectively. The segments are connected by oblique bolts in the circumferential direction; the pipe rings are connected by 28 or 28 groups of bent bolts uniformly distributed in the circumferential direction in the longitudinal direction; the lining ring is double-sided wedge-shaped; the internal components are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com