Manual punching supplementation device

A technology for supplementary punching and needle punching, which is applied in the field of manual supplementary punching devices, can solve problems such as troublesome and missed punching, and achieve the effect of perfect function, simple structure and elimination of quality risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

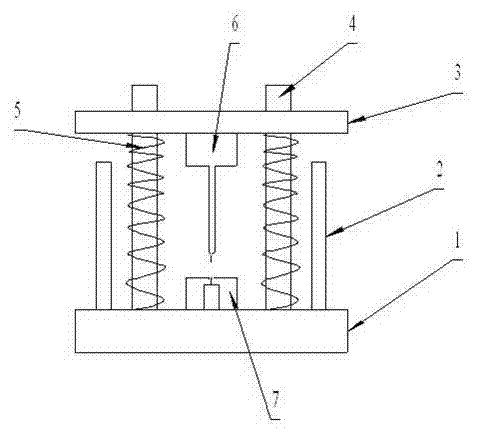

[0008] Such as figure 1 As shown, the manual supplementary punching device includes a lower plate 1, an upper plate 3, a sliding column 4, a punching needle 6 and an insert 7, and the lower plate 1 is equipped with a limit column 2, a sliding column 4, and an insert 7 , the spool 4 is equipped with a compression spring 5, the upper plate 3 passes through the spool 4 and is installed above the compression spring 5, the punch 6 is installed below the upper plate 3, and the The punch pin 6 is located above the insert 7 .

[0009] Put the leaked part of the oil ring wire on the insert 7, and let the position of the supplementary punch coincide with the hole position on the insert 7. The compression spring 5 lifts the upper plate 3. When the position of the wire is adjusted, use The hand hammer exerts an impact force on the upper plate 3, the upper plate 3 moves along the sliding column 4, and the punching needle 6 moves downward to complete the impulsive action.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com