A process for preventing local weak sand mold from crushing in core assembly

A process method, sand mold technology, applied in the direction of core, casting mold, casting mold composition, etc., can solve problems such as poor metal structure, affecting core positioning accuracy, sand mold crushing, etc., to improve positioning accuracy and accuracy, The effect of eliminating the risk of crushing and solving the difficulty of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

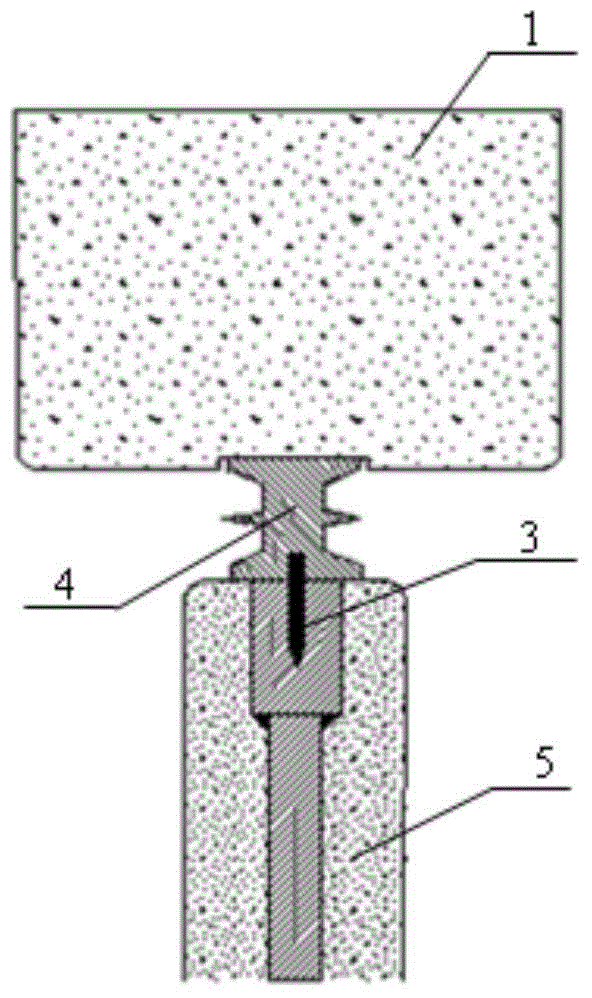

[0021] Embodiment 1: A kind of process method that prevents local weak sand mold from collapsing in core assembly, such as figure 2 Shown: the method includes the following steps:

[0022] a. In the mold making stage, install positioning pins on the corresponding parts of the outer mold, and the positioning pins are metal pins of Φ3-5mm;

[0023] b. Make the metal support rod 2 weldment, the shape of the end is consistent with the appearance of the casting, drill a Φ3.5-5.5mm hole in the center, and weld some auxiliary support devices on the lower part of the support rod 2. The auxiliary support devices are in the place The lower part of the support rod 2 is welded with round steel, and the rib structure is welded between the round steel and the support rod. The number and shape of the auxiliary support devices are determined according to the shape of the corresponding area of the casting and the weight of the core;

[0024] c. During the molding process, insert the above-...

Embodiment 2

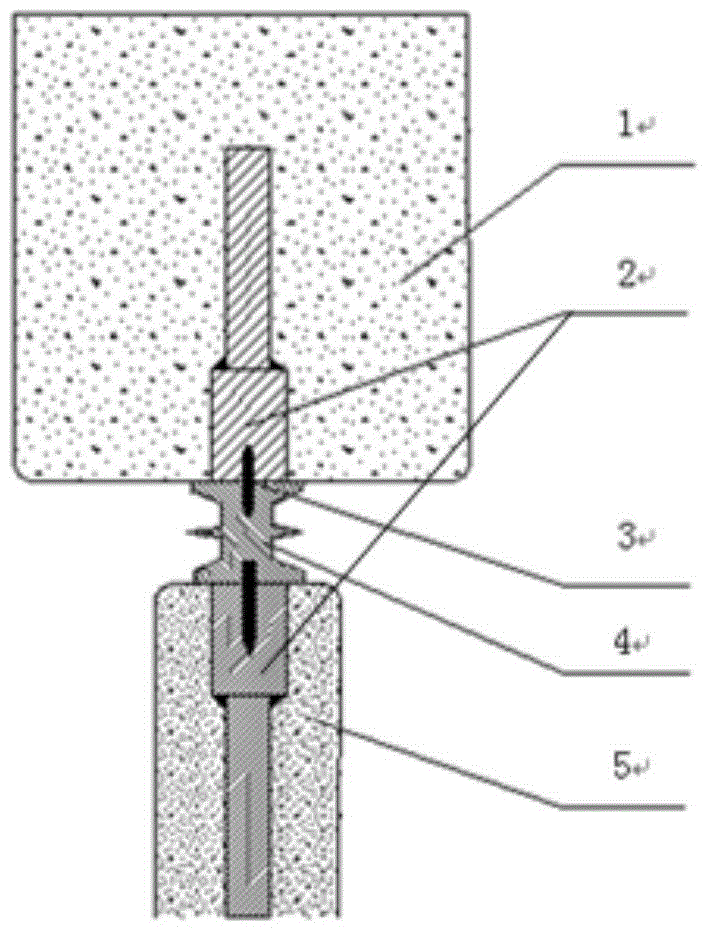

[0026] Embodiment two: a kind of technological method that prevents local weak sand mold from collapsing in core assembly, such as figure 1 Shown: the method includes the following steps:

[0027] a. In the mold making stage, install positioning pins on the corresponding parts of the outer mold 1, and the positioning pins are metal pins of Φ3-5mm;

[0028] b. Make metal support rod welding parts, the shape of the end is consistent with the appearance of the casting, the center drills a Φ3.5-5.5mm hole, and welds some auxiliary support devices on the lower part of the support rod. The auxiliary support device is on the support The lower part of the rod 2 is welded with round steel, and the rib structure is welded between the round steel and the support rod. The number and shape of auxiliary support devices are determined according to the shape of the corresponding area of the casting and the weight of the core;

[0029] c. During the molding process, insert the prepared meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com