Construction method of water permeable cement pavement

A construction method, cement pavement technology, applied to roads, roads, on-site cohesive pavements, etc., can solve the problems of low strength, poor water permeability of permeable cement concrete, complex construction process, etc., and achieve good flexural elasticity , Inhibit ground dust, simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

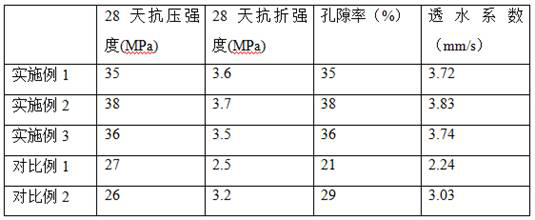

Examples

Embodiment 1

[0029] Example 1 (construction in summer, maximum temperature 32°C)

[0030] (1) At room temperature, add 2.5 parts of hectorite to 100 parts of water, stir well and let it stand for 20 hours, then add 300 parts of coarse aggregate, 110 parts of fine aggregate and 80 parts of cement, after stirring evenly, add mica powder 6 parts, stirred for 25 minutes to obtain permeable concrete slurry;

[0031] (2) The permeable concrete slurry obtained in step (1) is paved on the subgrade by mechanical paving, the paving speed is 0.6m / min, the thickness is 15 cm, and the vibrating leveling is carried out with a plate vibrator;

[0032] (3) After the initial setting of the concrete (this process takes 5.5 hours), cover the cement pavement with plastic film, water every 36 hours, and maintain the cement pavement for 6 days to complete the construction.

Embodiment 2

[0033] Example 2 (spring construction, maximum temperature 17°C)

[0034] (1) At room temperature, add 5 parts of hectorite to 120 parts of water, stir well and let it stand for 30 hours, then add 500 parts of coarse aggregate, 110 parts of fine aggregate and 120 parts of cement, after stirring evenly, add mica 10 parts of powder, stirred for 30 minutes to obtain permeable concrete paste;

[0035] (2) Spread the permeable concrete slurry obtained in step (1) onto the roadbed by mechanical paving at a paving speed of 0.6m / min and a thickness of 15 cm, and vibrate leveling with a flat vibrator;

[0036] (3) After the initial setting of the concrete (the process takes 6 hours), cover the cement pavement with plastic film, water every 36 hours, and maintain the cement pavement for 10 days to complete the construction.

Embodiment 3

[0037] Example 3 (construction in winter, temperature is 0~12°C)

[0038] (1) At room temperature, add 4 parts of hectorite to 120 parts of water, stir well and let stand for 25 hours, then add 400 parts of coarse aggregate, 110 parts of fine aggregate and 120 parts of cement, stir well, then add mica 10 parts of powder, stirred for 30 minutes to obtain permeable concrete paste;

[0039] (2) The permeable concrete slurry obtained in step (1) is paved on the subgrade by mechanical paving, the paving speed is 0.6m / min, the thickness is 15 cm, and the vibrating leveling is carried out with a plate vibrator;

[0040] (3) After the initial setting of the concrete (the process takes 7 hours), cover the cement pavement with plastic film, water every 48 hours, and maintain the cement pavement for 14 days to complete the construction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com