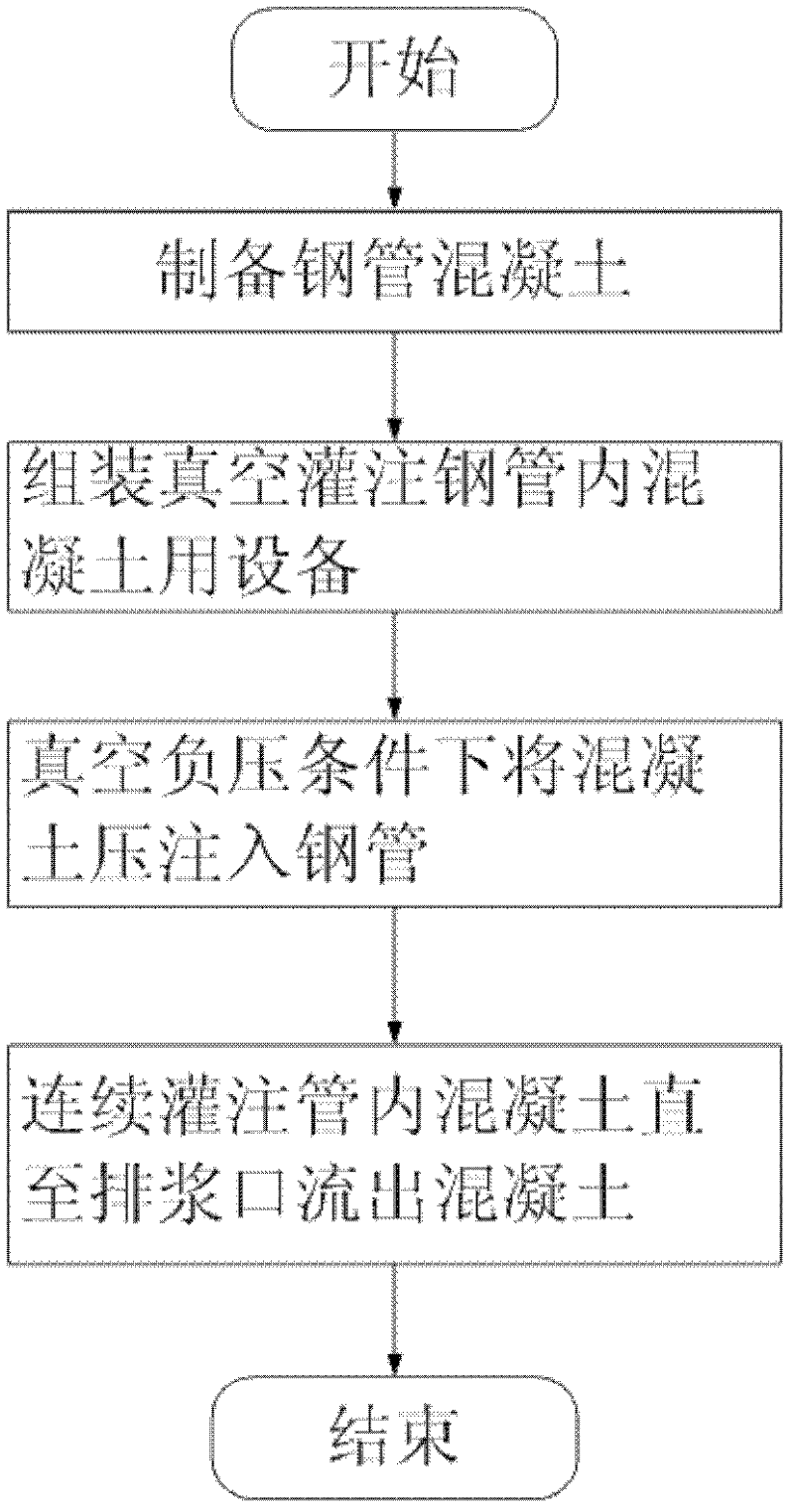

Method of Vacuum Pouring Concrete in Steel Tube

A technology of steel pipe concrete and pouring concrete, which is applied in construction, building structure, and construction material processing, and can solve the problems of affecting the core concrete hoop effect and affecting the bonding of core concrete and steel pipe walls, so as to reduce the phenomenon of debonding , Improving compactness and suppressing the formation of gas film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

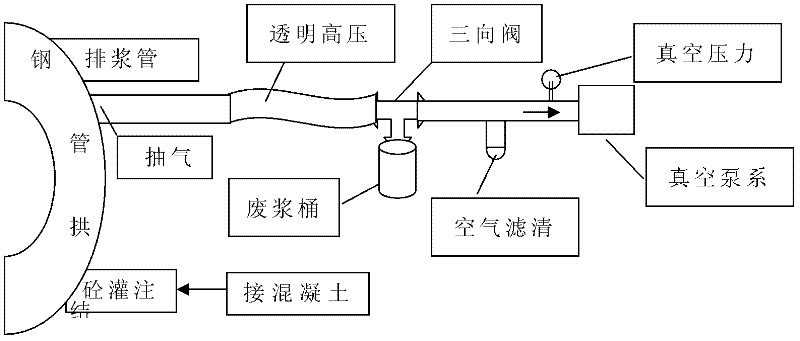

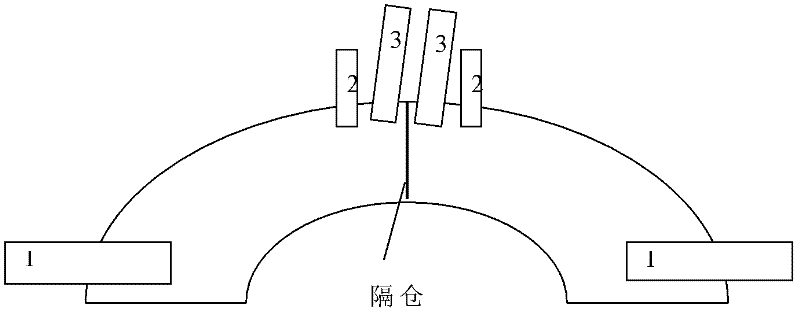

Method used

Image

Examples

Embodiment 1

[0033] Preparation of steel tube concrete: Add 0.8% water reducer and a certain amount of expansion agent to the concrete, and control the air-entraining amount of the water reducer below 15%, and mix in different contents of fly ash as shown in Table 1. The prepared concrete has a viscosity of For, fluidity, and yield stress parameters are shown in Table 1. The air content of the concrete is controlled at 2.0%, and the air film produced during the pumping and jacking construction is relatively thin. When the expansion rate of the concrete is above 2.5×10-4 The air film gap formed can then be compensated. The other steps of vacuum pouring the concrete in the steel pipe are the same as above.

[0034] Using cement and different amounts of fly ash (level II) as the cementitious material, the influence of the trial-produced fly ash content on the rheological properties of cement paste is shown in Table 1:

[0035] Table 1 Effect of fly ash on the rheological properties of cement...

Embodiment 2

[0039] Add 0.8% water reducer and a certain amount of expansion agent to the concrete, and the amount of fly ash is 15%. The air content of the concrete mixture has a great influence on the expansion rate of the concrete under the condition of the steel pipe. Therefore, in order to ensure the close combination of concrete and steel pipe wall, the air content of concrete must be limited within a certain range.

[0040] The expansion properties of concrete mixtures with different air contents in each group tested under the condition of closed steel pipes are shown in Table 2.

[0041] Table 2 The expansion rate of concrete under the condition of closed steel pipes (×10 -4 )

[0042]

[0043]The above test results show that when the gas content of steel pipe concrete is 2.3% to 3.0%, under the action of pumping pressure and concrete self-weight, about 0.05% to 0.1% of the concrete volume will be enriched in the inner wall of the steel pipe, which will cause A circular gap wi...

Embodiment 3

[0045] Select 4 groups of test pieces and pump them to the vacuum states of different negative pressures (0, -0.02MPa, -0.06MPa, -0.08MPa) respectively. Other conditions and steps are the same as in Example 1.

[0046] Then take out the cement slurry at the top of the steel pipe, and carry out the rheological properties (viscosity and yield stress) test of the cement slurry to study and analyze the influence of negative pressure on the rheological properties of the cement slurry.

[0047] Table 3 Test results of rheological properties of cement paste under different negative pressures

[0048]

[0049] It can be seen from Table 3 that after the cement slurry is treated with negative pressure, the viscosity and yield stress of the top slurry both decrease to a certain extent, indicating that the cement slurry prepared with this water reducing agent does not segregate and bleed under negative pressure. , will not cause deterioration of the workability of the cement slurry, no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com