High-silicon gradient silicon steel thin strip and preparation method thereof

A technology of silicon steel and thin strip, which is applied in the direction of solid-state diffusion coating, coating, metal material coating technology, etc., can solve the problems of severe cold brittleness, etc., and achieve the effect of fast reaction speed, excellent overall performance and continuous process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Raw materials: silicon content 2.5%, balance Fe; thin silicon steel strip with a thickness of 0.28mm and a width of 80mm. Through alkali cleaning, electrolytic cleaning, drying and other processes, the grease and dust on the surface are washed away to obtain a clean surface.

[0036] 2. Roughness treatment is carried out on the surface of the strip steel, and the roughness Ra=1.57μm;

[0037] 3. Enter the heating furnace, preheat to 1000°C under the condition of non-oxidizing atmosphere protected by inert gas, and keep warm for 2 minutes;

[0038] 4. Enter the reduction zone and heat to 1150°C under the non-oxidizing atmosphere of the mixture of hydrogen and inert gas for 2 minutes;

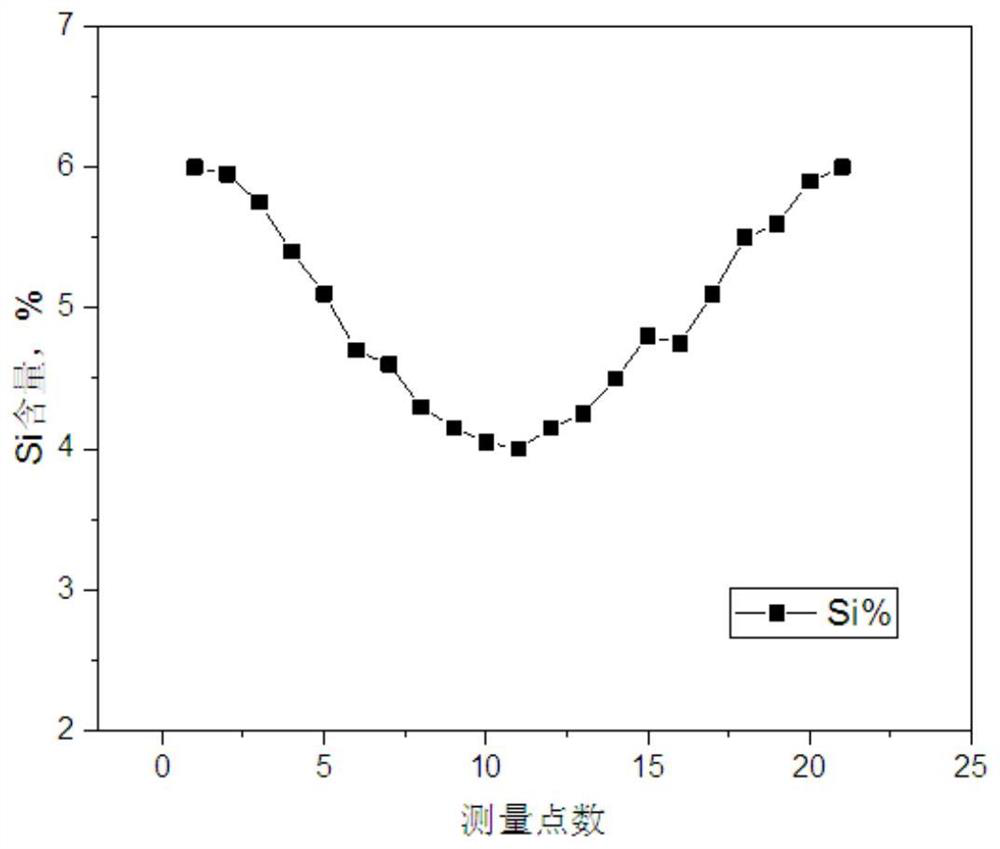

[0039] 5. Enter the first section of siliconizing area, spray nitrogen + silicon tetrachloride mixed gas on the upper and lower surfaces of the silicon steel strip through several sets of nozzles, the volume fraction of silicon tetrachloride is 20%, and react under the heating conditio...

Embodiment 2

[0046] 1. Raw materials: silicon content of 2.5%; thin silicon steel strip with a thickness of 0.17mm and a width of 200mm. Through alkali cleaning, electrolytic cleaning, drying and other processes, the grease and dust on the surface are washed away to obtain a clean surface.

[0047] 2. Roughness treatment is carried out on the surface of the strip steel, and the roughness Ra=1.36μm;

[0048] 3. Enter the heating furnace, preheat to 900°C under the condition of non-oxidizing atmosphere protected by inert gas, and keep warm for 2 minutes;

[0049] 4. Enter the reduction zone and heat to 1150°C under the non-oxidizing atmosphere of the mixture of hydrogen and inert gas for 2 minutes;

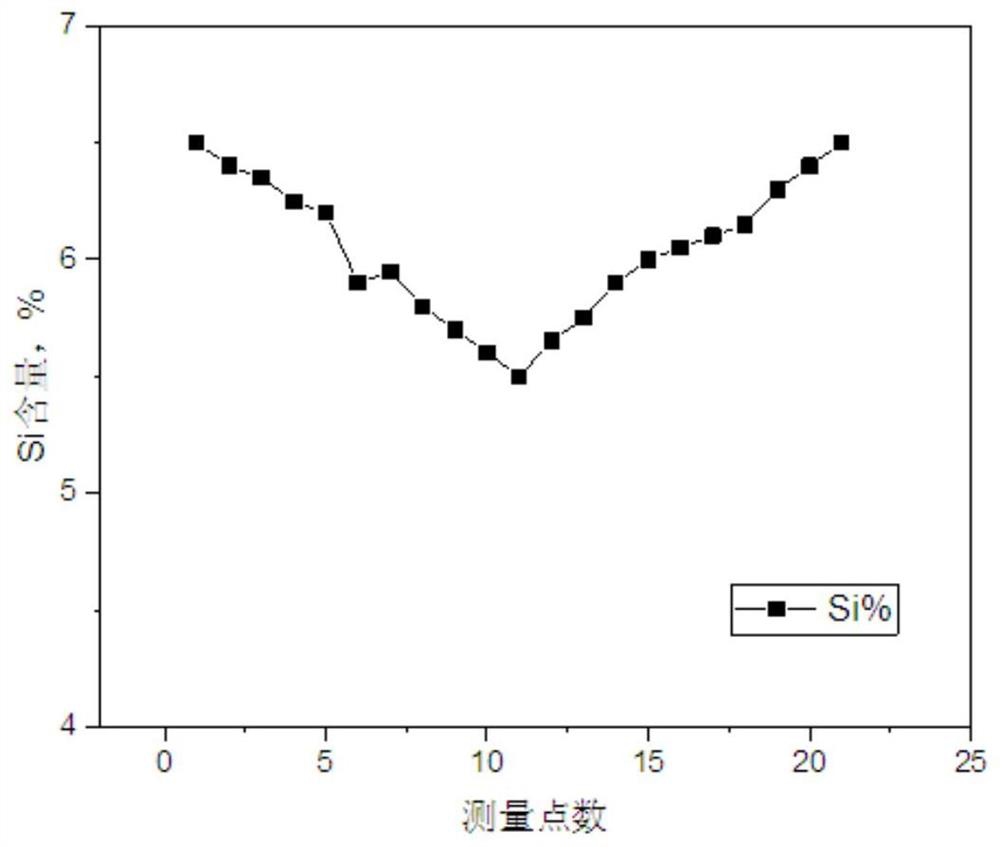

[0050] 5. Enter the first section of siliconizing area, spray nitrogen + silicon tetrachloride mixed gas on the upper and lower surfaces of the silicon steel thin strip through several sets of nozzles, the volume fraction of silicon tetrachloride is 30%, and react under the heating condition of...

Embodiment 3

[0055] 1. Raw materials: silicon content 2.8%; thin silicon steel strip with a thickness of 0.3mm and a width of 500mm. Through alkali cleaning, electrolytic cleaning, drying and other processes, the grease and dust on the surface are washed away to obtain a clean surface.

[0056] 2. Roughness treatment is carried out on the surface of the strip steel, and the roughness Ra=1.65μm;

[0057] 3. Enter the heating furnace, preheat to 1050°C under the condition of non-oxidizing atmosphere protected by inert gas, and keep warm for 2 minutes;

[0058] 4. Enter the reduction zone and heat it to 1140°C under the non-oxidizing atmosphere of the mixture of hydrogen and inert gas for 3 minutes;

[0059] 5. Enter the first section of siliconizing area, spray nitrogen + silicon tetrachloride mixed gas on the upper and lower surfaces of the silicon steel thin strip through several groups of nozzles, the volume fraction of silicon tetrachloride is 10%, and react under the heating condition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com