A kind of preparation method of high-strength, high-hardness water-atomized pre-alloyed steel powder

A technology of alloy steel powder and high hardness, which is applied in the field of preparation of high-strength, high-hardness water atomized pre-alloyed steel powder, which can solve the problems such as the degradation of matrix material performance, achieve performance improvement, overcome high hydrogen loss, and improve application performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

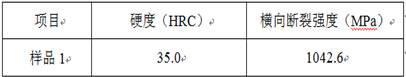

Embodiment 1

[0057] A method for preparing high-strength, high-hardness water-atomized pre-alloyed steel powder, including batching, smelting process, atomization, reduction, and post-treatment.

[0058] 1. Ingredients

[0059] The composition content meets the following requirements: Mn<0.50%, P<0.04%, Si<0.2%, S<0.04%, Cr+Ni+Cu+Mo≤0.20% of high-quality ordinary carbon steel scrap and pig iron as raw materials, spare.

[0060] The weight ratio of the high-quality common carbon steel scrap: pig iron is 1:2.

[0061] 2. Smelting process

[0062] The smelting process includes EBT electric furnace smelting, electric furnace tapping, and LF refining furnace smelting.

[0063] The EBT electric furnace is smelted, and the smelting temperature is 1550°C.

[0064] When the EBT electric furnace is smelted and the electric furnace is tapping, the carbon content at the control end point is ≥0.15%.

[0065] The EBT electric furnace smelting, when the composition of the electric furnace molten stee...

Embodiment 2

[0094] A method for preparing high-strength, high-hardness water-atomized pre-alloyed steel powder, including batching, smelting process, atomization, reduction, and post-treatment.

[0095] 1. Ingredients

[0096] The composition content meets the following requirements: Mn<0.50%, P<0.04%, Si<0.2%, S<0.04%, Cr+Ni+Cu+Mo≤0.20% of high-quality ordinary carbon steel scrap and pig iron as raw materials, spare.

[0097] The weight ratio of high-quality common carbon steel scrap: pig iron is 1:1.

[0098] 2. Smelting process

[0099] The smelting process includes EBT electric furnace smelting, electric furnace tapping, and LF refining furnace smelting.

[0100] The EBT electric furnace is smelted, and the smelting temperature is 1550°C.

[0101] When the EBT electric furnace is smelted and the electric furnace is tapping, the carbon content at the control end point is ≥0.15%.

[0102] The EBT electric furnace smelting, when the composition of the electric furnace molten steel me...

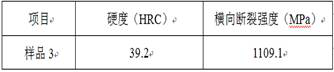

Embodiment 3

[0131] A method for preparing high-strength, high-hardness water-atomized pre-alloyed steel powder, including batching, smelting process, atomization, reduction, and post-treatment.

[0132] 1. Ingredients

[0133] The composition content meets the following requirements: Mn<0.50%, P<0.04%, Si<0.2%, S<0.04%, Cr+Ni+Cu+Mo≤0.20% of high-quality ordinary carbon steel scrap and pig iron as raw materials, spare.

[0134] The weight ratio of the high-quality common carbon steel scrap: pig iron is 1:2.

[0135] 2. Smelting process

[0136] The smelting process includes EBT electric furnace smelting, electric furnace tapping, and LF refining furnace smelting.

[0137] The EBT electric furnace is smelted, and the smelting temperature is 1550°C.

[0138] When the EBT electric furnace is smelted and the electric furnace is tapping, the carbon content at the control end point is ≥0.15%.

[0139] The EBT electric furnace smelting, when the composition of the electric furnace molten stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com