Method for producing long-chain glycosylated sophoricoside

A sophorin and glucose-based technology, applied in the field of enzyme engineering and fermentation engineering, can solve the problems of low efficiency of long-chain sophoroside and limitation of the output of long-chain glycosylated sophoroside

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1: Preparation and expression of different cyclodextrin glucosyltransferases

[0057] Specific steps are as follows:

[0058] Chemically synthesize the gene encoding cyclodextrin glucosyltransferase (the nucleotide sequence is shown in SEQ ID NO.1); after the obtained gene and the pET-20b (+) plasmid are digested with double enzymes (NdeI and XhoI) Perform ligation, transform Escherichia coli JM109, spread the transformation product on LB solid medium, culture at 37°C for 8 hours, pick transformants on LB solid medium, insert them into LB liquid medium for culture, and extract after culturing at 37°C for 10 hours Plasmid, the plasmid is sequenced to obtain the correct sequenced recombinant plasmid pET20b-CGT; the sequenced correct recombinant plasmid pET20b-CGT is transformed into Escherichia coli E.coli BL21 (DE3), and the recombinant Escherichia coli pET20b-CGT / E. coli BL21.

[0059] Using the whole plasmid PCR technology, the obtained recombinant plasmid pE...

Embodiment 2

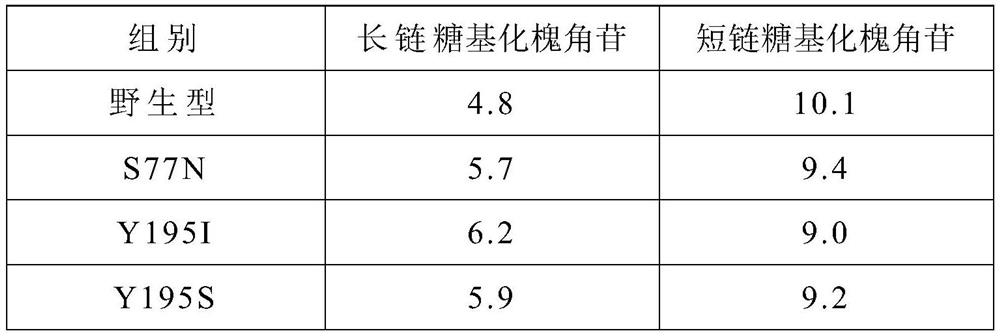

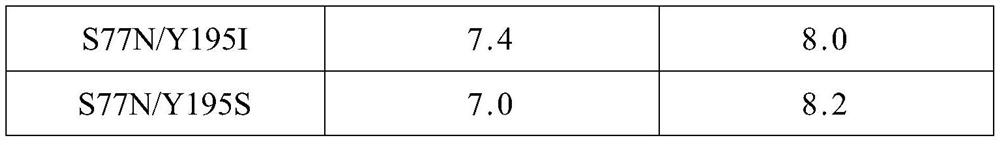

[0073] Example 2: Product Specificity of Different Cyclodextrin Glucosyltransferases to Different Glycosylated Sophoricrosides

[0074] Specific steps are as follows:

[0075] Sophoridin (purchased from Sigma Company) was dissolved in dimethyl sulfoxide (DMSO) to prepare a final concentration of 1g / L sophoridin solution; the water-soluble starch was dissolved in PBS buffer (50mM, pH 7) prepared in a maltodextrin solution with a final concentration of 40g / L; the lyophilized mutants S77N, Y195S, Y195I, S77N, S77N / Y195S and the pure enzymes of S77N / Y195I obtained in Example 1 were dissolved in PBS buffer respectively solution (50mM, pH 7) to prepare a CGTase enzyme solution with a final concentration of 15U / L; respectively take 200μL sophoridin solution, 600μL water-soluble starch solution and 200μL CGTase enzyme solution and mix them in a 2mL small tube with a cover, and put them in a 40 ℃, 120rpm shaker and shake slowly for 20-24h to obtain a reaction solution.

[0076] Detec...

Embodiment 3

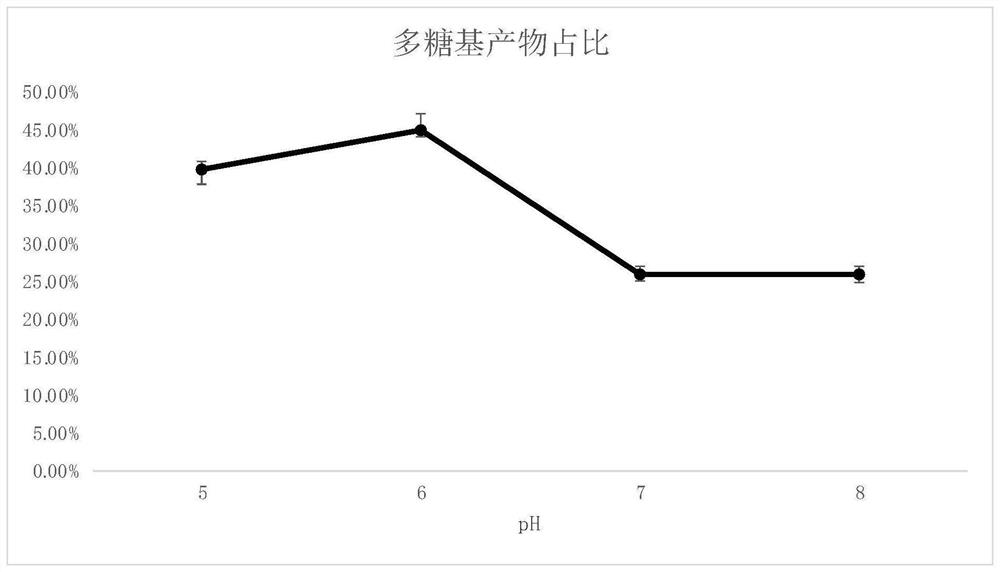

[0083] Example 3: Effect of Reaction Temperature on Yield of Long-chain Glycosylated Sophoridin

[0084] Specific steps are as follows:

[0085] On the basis of Example 2, the mutant S77N / Y195I was selected, and the reaction temperatures were replaced by 30°C, 35°C, 40°C, 45°C, 50°C, 55°C, and 60°C, respectively.

[0086] Referring to Example 2, short-chain glycosylated sophorosides in the reaction solution were detected by HPLC (herein, the short-chain glycosylated sophorosides were monoglycosylated sophoroside, diglycosylated sophoroside and triosyl mixture of sophoridin) and long-chain glycosylated sophoroside (herein long-chain glycosylated sophoroside is tetraglycosylated sophoroside, pentaglycosylated sophoroside and hexaglycosylated sophoroside The molar content of the mixture of glycosides), and calculate the ratio (% ), the test results are shown in Table 3.

[0087]It can be seen from Table 3 that when the temperature is 45-50°C, the yield of long-chain glycosylat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com