Preparation method of single-component waterborne epoxy SBS composite modified emulsified asphalt

A composite modification, water-based epoxy technology, applied in building components, building insulation materials, construction, etc., can solve the problems of low temperature stability, low tensile strength and elongation at break, polluted water quality, etc., to improve durability Low temperature performance, improvement of tensile strength and elongation at break, and improvement of low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Soap preparation:

[0046] Heat 250 grams of water to 60°C, add 27.5 grams of polyethylene glycol (supplier, Shanghai Titan Technology, model 01050891), stir and dissolve, then add 7.5 grams of IPDI (supplier, Shanghai Titan Technology, model 01072400) , 5.3g of 2,2-dimethylolpropionic acid (supplier, Shanghai Mokai Biotechnology Co., Ltd., SY004305) and 0.1 gram of di(dodecylsulfide) diisooctyltin, stirred at a speed of 300r / min Mix for 10 minutes and react at 60-80°C for 4 hours to obtain a water-based polyurethane solution with a viscosity of 3200mPa.s, namely soap.

Embodiment 2

[0048] Preparation of maleic anhydride / SBS modified asphalt:

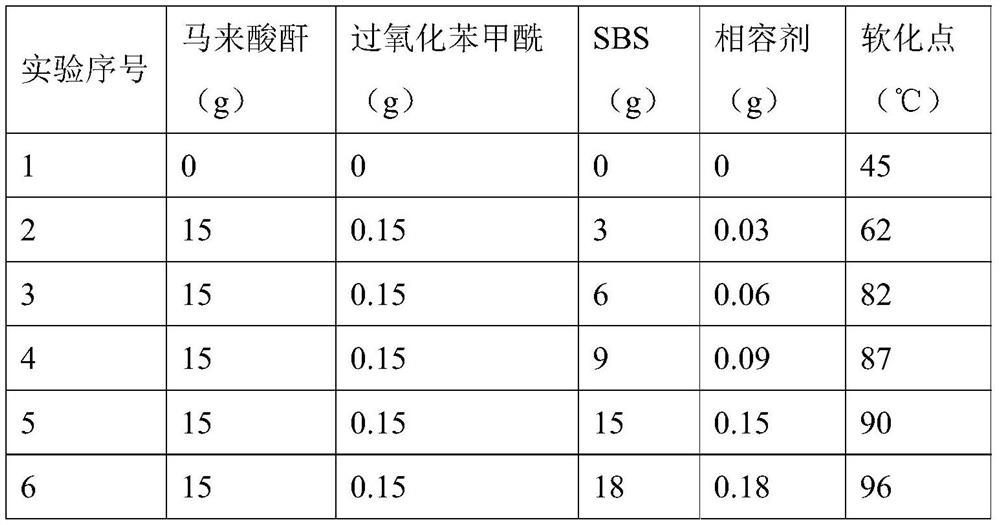

[0049] 250 grams of 70# base asphalt is heated to 150 ° C, according to the formula in Table 1, first mix maleic anhydride and 1% crosslinking agent dibenzoyl peroxide (BPO) based on the weight of maleic anhydride, and then add Add it to the base asphalt, stir and mix, and react at 150°C for 5 hours to obtain a cross-linked maleic anhydride modified asphalt. Add SBS (Baling Petrochemical Company, model 791h) and 1% compatibilizer by weight of SBS (Dayue Plastic Technology Co., Ltd., model DY-307) into the maleic anhydride modified asphalt, and stir at 150°C Mix for 5 hours to obtain maleic anhydride / SBS modified asphalt.

[0050] Table 1 Various maleic anhydride / SBS modified asphalt

[0051]

Embodiment 3

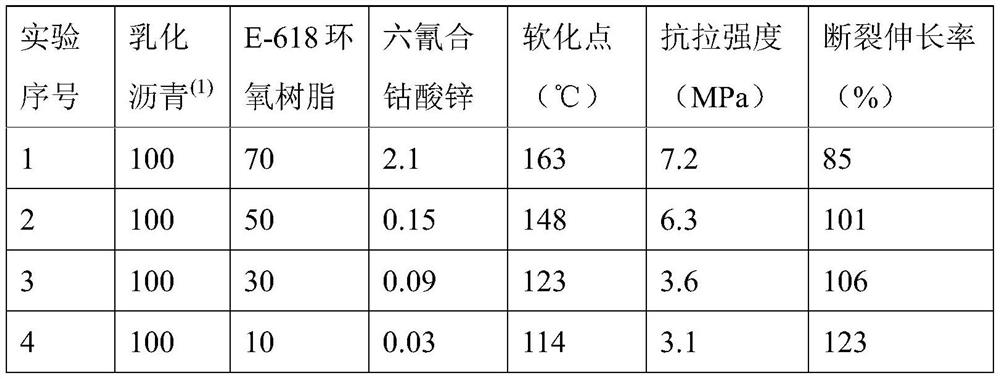

[0053] Preparation of one-component waterborne epoxy / SBS composite modified emulsified asphalt:

[0054] The maleic anhydride / SBS modified bitumen 100g that experiment number 5 in the embodiment 2 obtains is added in the soap liquid that obtains in the 100g embodiment 1, carries out shearing 15min with rotating speed 8500r / min, obtains the maleic anhydride / SBS modified asphalt. Emulsion of emulsified asphalt (referred to as emulsified asphalt).

[0055] Take by weighing E-618 epoxy resin (Shanghai Resin Factory Co., Ltd.), zinc hexacyanocobaltate and maleic anhydride / SBS modified emulsified pitch based on epoxy resin weight 0.3wt% by the formula weight of Table 2 with rotating speed 1500r / min to shear for 15 minutes and mix evenly to obtain a one-component water-based epoxy / SBS composite modified emulsified asphalt.

[0056] Table 2 Performance comparison of various single-component waterborne epoxy / SBS composite modified emulsified asphalt products

[0057]

[0058] Not...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com