Restaurant waste and waste water treatment system

A waste water treatment system and technology for catering waste, applied in the direction of heating water/sewage treatment, water/sludge/sewage treatment, sludge treatment, etc., can solve problems such as lack of catering waste, automatic separation of solids and liquids, etc. , to achieve the effect of reliable connection, convenient detection and maintenance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in detail below in conjunction with accompanying drawing:

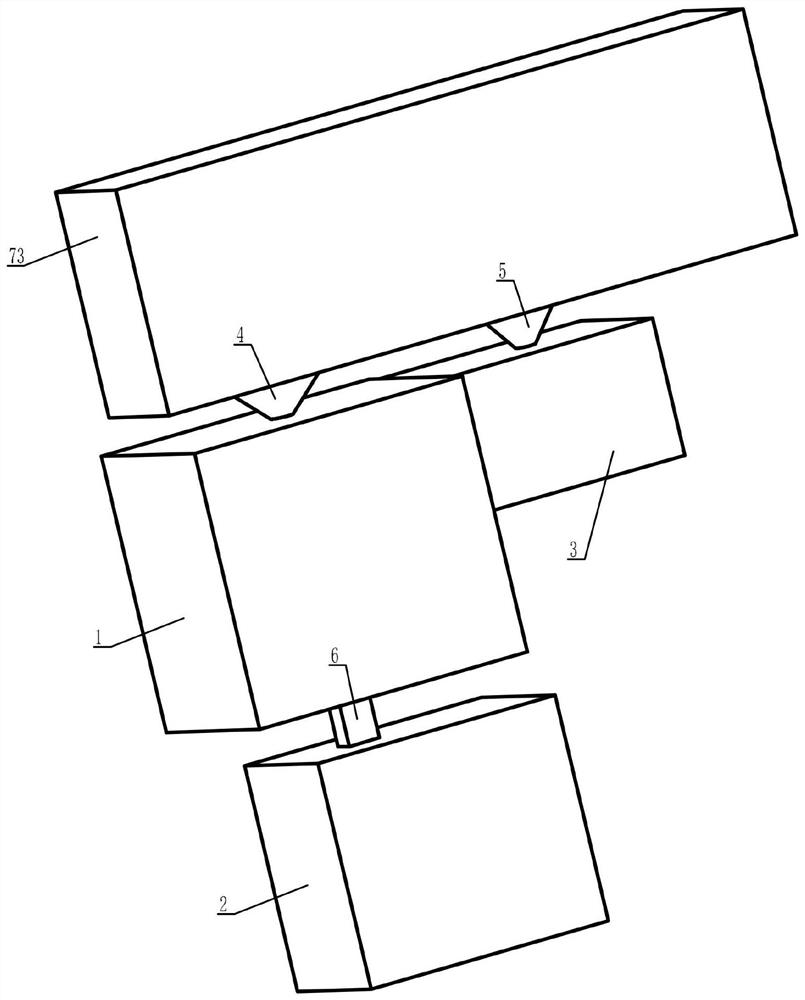

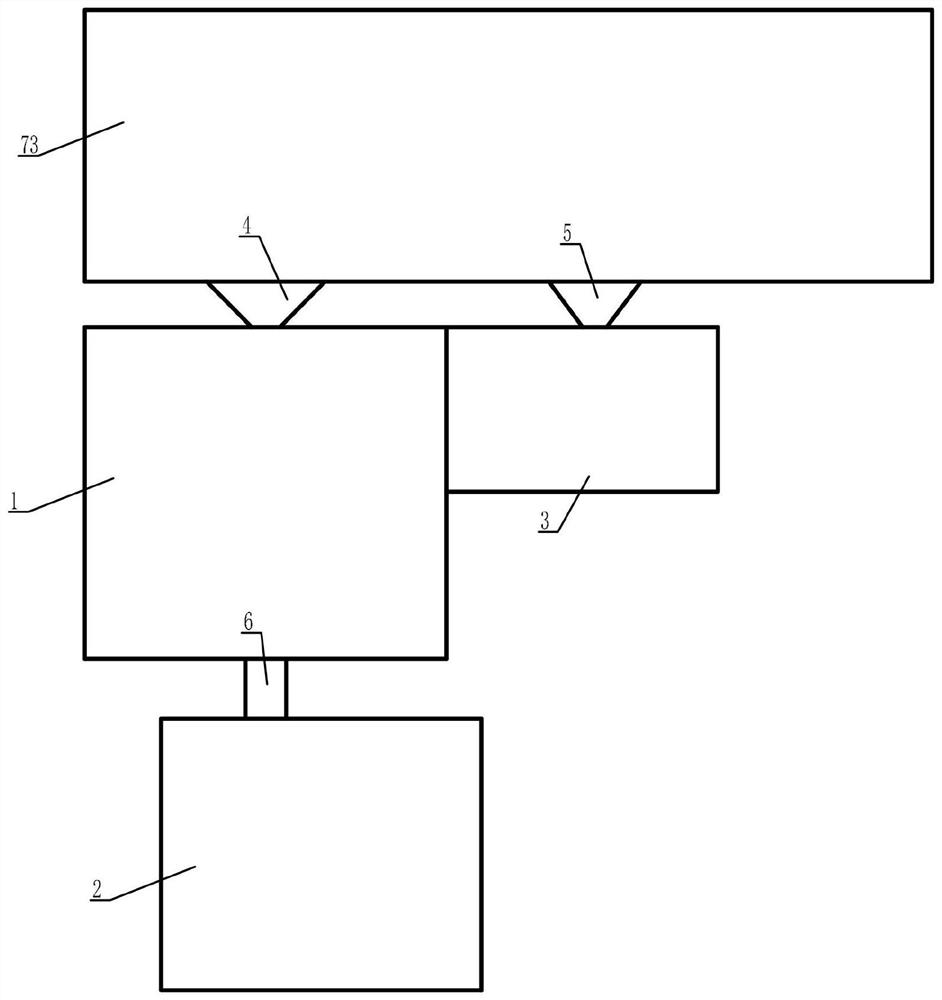

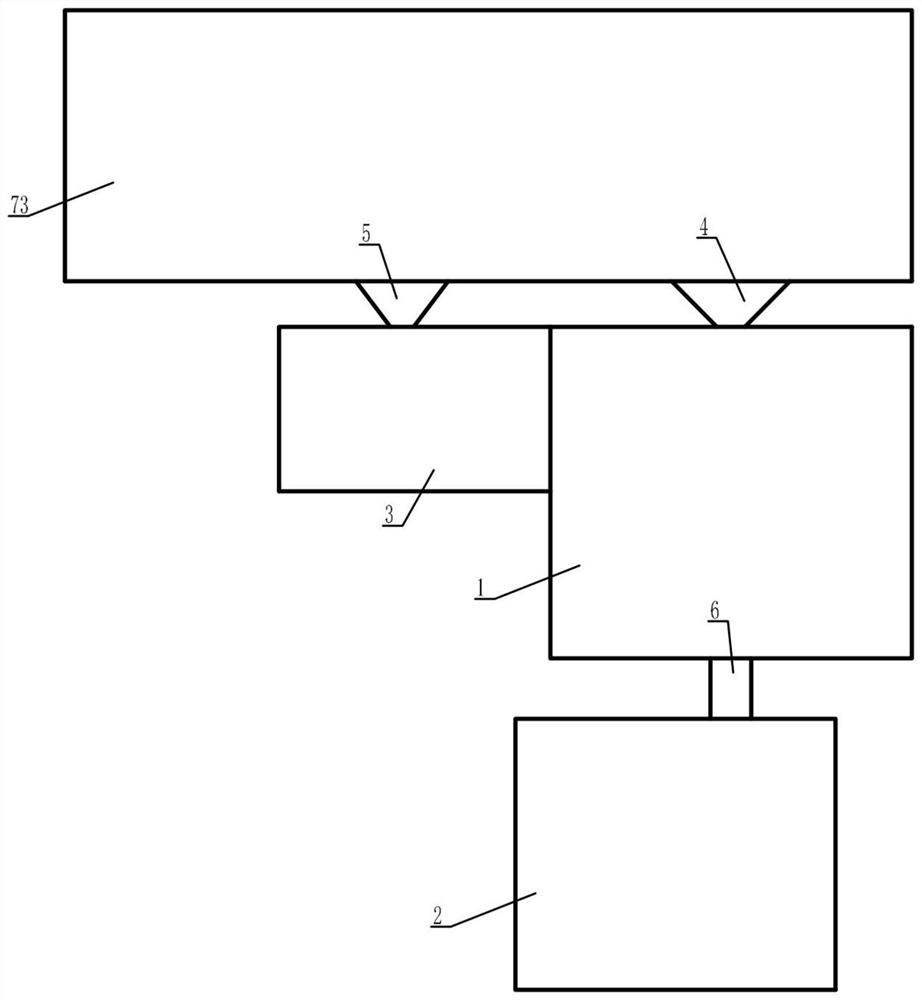

[0033] refer to Figure 1 to Figure 10 A food waste and wastewater treatment system provided by the present invention includes a garbage crushing box 1 and a separation box 73. The top of the garbage crushing box 1 is provided with a food and beverage solid waste inlet 4, and the right side of the garbage crushing box 1 is The side is provided with waste water treatment box 3, and the bottom surface of described rubbish crushing box 1 is communicated with the top surface of heat treatment box 2 through connecting pipe 6, and the lower surface of described separation box 73 is connected with catering solid waste inlet 4, catering wastewater inlet. The top of 5 communicates, and the inside of the separation box 73 is provided with a temporary storage chamber 75, and the left side of the temporary storage chamber 75 is connected with a revolving door 77 through a hinge shaft 76, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com