Al-doped ZnO nano rod as well as preparation method and application thereof

A technology of nanorods and seed layers, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, and can solve the problems that ZnO nanomaterials are not fully utilized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

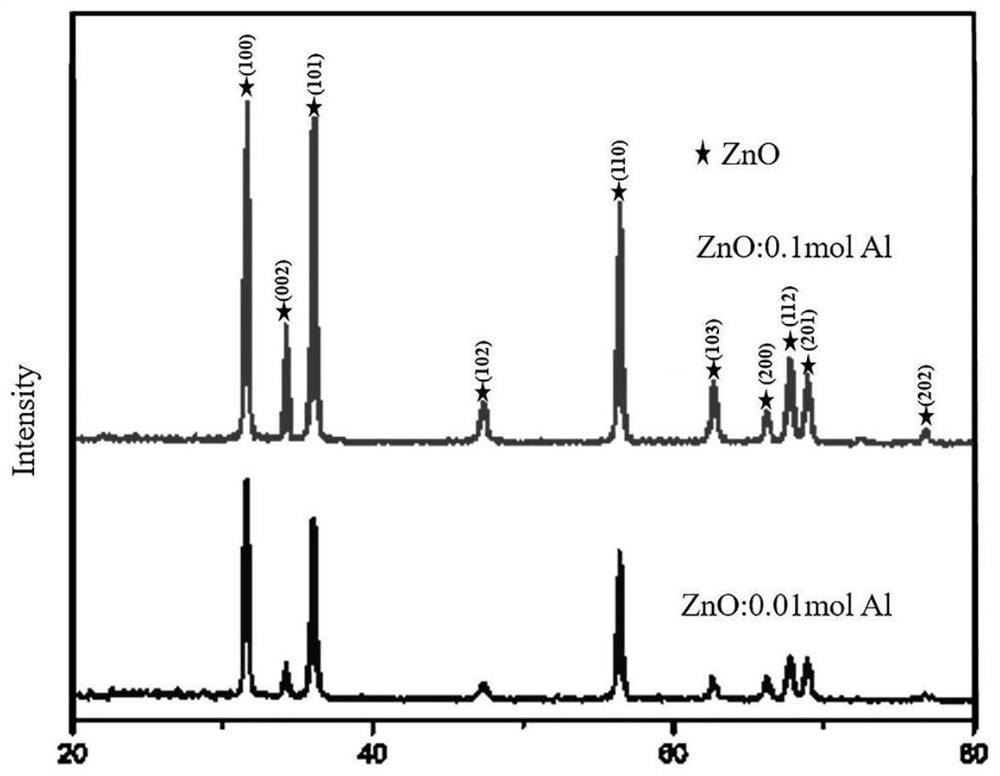

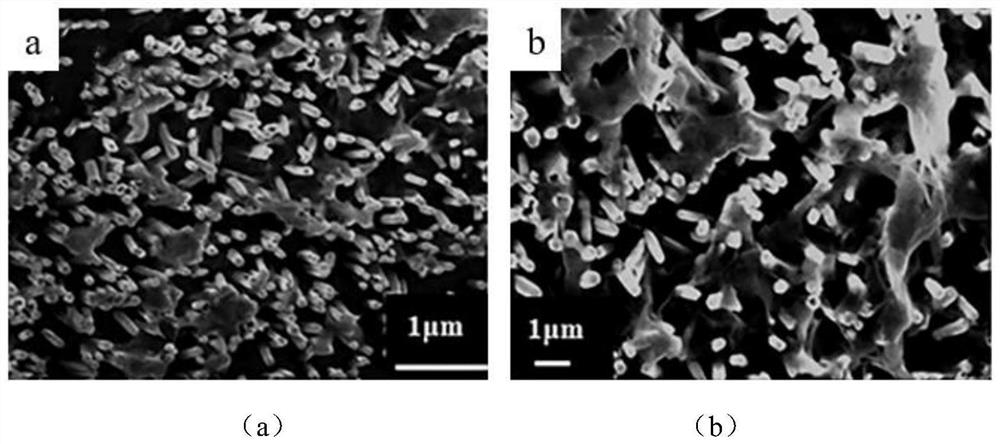

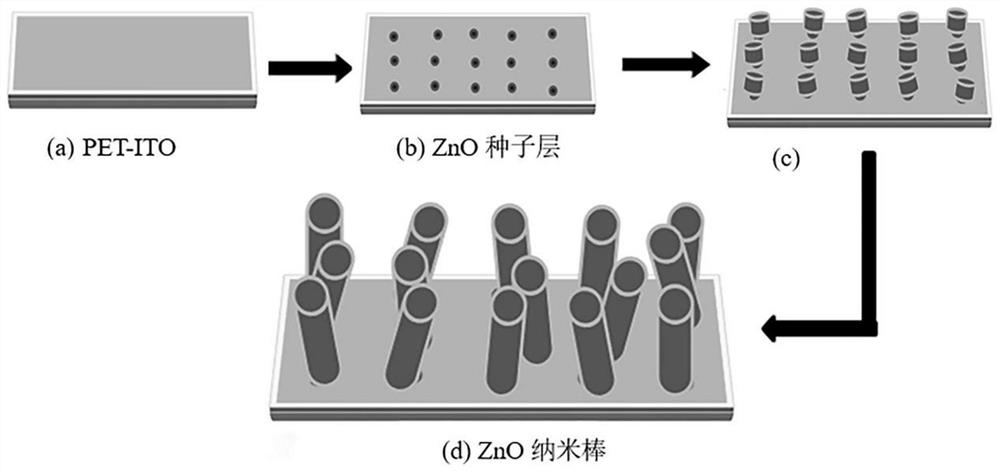

[0034] The invention discloses an Al-doped ZnO nanorod and its preparation method and application. The preparation method comprises the following steps:

[0035] The first step of flexible substrate preparation: Cut the PET-ITO flexible substrate into a square of 1.0cm×1.0cm, clean it ultrasonically with acetone (10min) and ethanol (10min), take it out and transfer it to deionized water, Clean again with ultrasonic waves for 10 minutes, then take out the PET-ITO flexible substrate, put it in an oven, and dry it at 70°C for later use, so that the PET-ITO flexible substrate remains dry. During the growth process on the PET-ITO surface, it will seriously affect the growth of the final ZnO nanorods on the PET-ITO surface.

[0036]The second step is to sputter the PET-ITO flexible substrate and plate the seed layer: deposit the dried PET-ITO flexible substrate on the substrate by radio frequency magnetron sputtering (using high-purity ZnO sheet as the target material) ZnO seed lay...

Embodiment 1

[0048] 1) Plating a ZnO seed layer on the surface of the PET-ITO substrate with an ion sputtering coater, the pressure is 10Pa, and the current is 6mA for 1min, and the current is 8mA for 4min;

[0049] 2) Prepare the precursor solution, Zn(NO 3 ) 2 ·6H 2 O, C 6 h 12 N 4 and Al 2 o 3 The molar ratio of Zn(NO 3 ) 2 ·6H 2 O and C 6 h 12 N 4 The molar concentration is 0.05mol / L, Al 2 o 3 The molar concentration is 0.005mol / L, and the magnetic stirrer stirs for 20min;

[0050] 3) Transfer the obtained precursor solution to a 40ml closed polytetrafluoroethylene stainless steel autoclave. Then, the substrate on which the ZnO seed layer has been deposited is vertically immersed in the precursor solution, and then placed in an oven to react at a constant temperature of 95°C for 3 hours, cooled to room temperature naturally, then taken out, and repeatedly washed with distilled water and absolute ethanol to remove the residues on the surface. salt, and dried at 60°C for ...

Embodiment 2

[0053] 1) Plating a ZnO seed layer on the surface of the PET-ITO substrate with an ion sputtering coater, the pressure is 10Pa, and the current is 6mA for 1min, and the current is 8mA for 4min;

[0054] 2) Prepare the precursor solution, Zn(NO 3 ) 2 ·6H 2 O, C 6 h 12 N 4 and Al 2 o 3 The molar ratio of Zn(NO 3 ) 2 ·6H 2 O and C 6 h 12 N 4 The molar concentration is 0.05mol / L, Al 2 o 3 The molar concentration is 0.025mol / L, and the magnetic stirrer stirs for 20min;

[0055] 3) Transfer the obtained precursor solution to a 40ml closed polytetrafluoroethylene stainless steel autoclave. Then, the substrate on which the ZnO seed layer has been deposited is vertically immersed in the precursor solution, and then placed in an oven to react at a constant temperature of 95°C for 3 hours, cooled to room temperature naturally, then taken out, and repeatedly washed with distilled water and absolute ethanol to remove the residues on the surface. salt, and dried at 60°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com