Flange mechanism

A technology of flanges and flanges, which is applied to the parts of grinding machine tools, manufacturing tools, sawing machine devices, etc., and can solve the problem that the fixing nut cannot be disassembled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

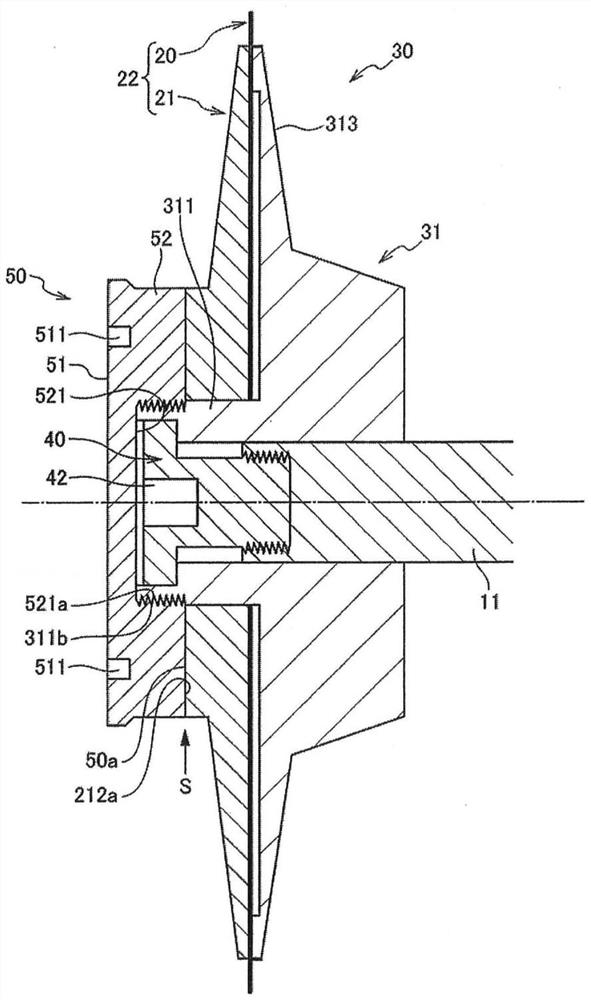

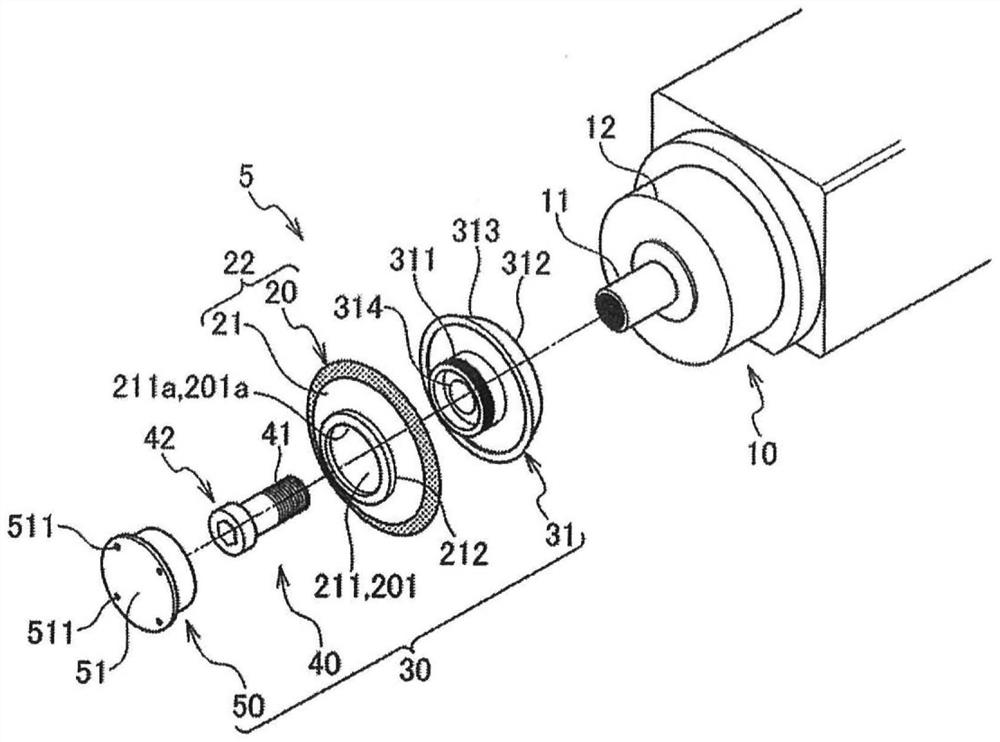

[0023] Hereinafter, one embodiment of the present invention will be described with appropriate reference to the drawings.

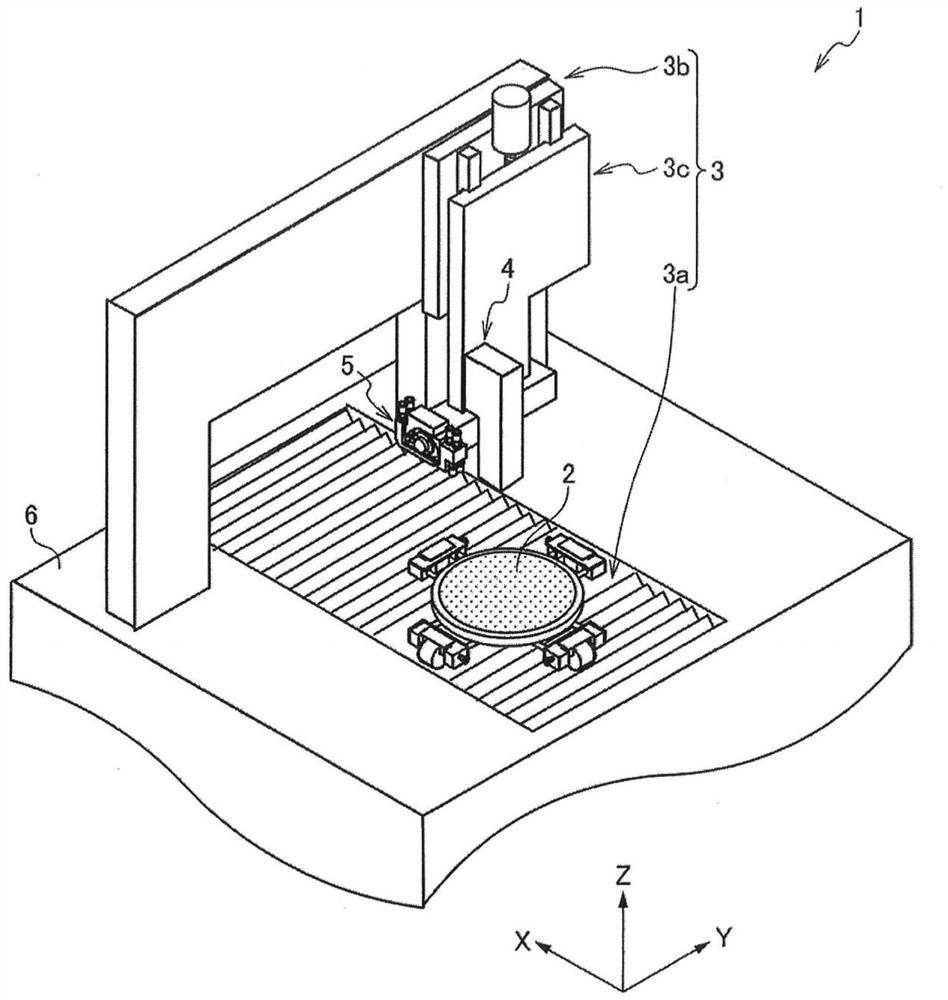

[0024] figure 1 The cutting device 1 is shown by image 3 The shown flange mechanism 30 is a machining device that cuts a workpiece with the cutting tool 20 clamped and fixed.

[0025] Such as figure 1 As shown, the cutting device 1 is configured to include a chuck table 2 , a moving member 3 , an imaging member 4 , and a cutting member 5 . Although the workpiece is not particularly limited, it is, for example, various plate-shaped processing materials such as plate-shaped semiconductor wafers, optical device wafers, plate-shaped inorganic material substrates, and plate-shaped ductile materials. In this embodiment, a case where a plurality of mutually perpendicular dividing lines are formed on the front surface of the workpiece will be described.

[0026] The chuck table 2 attracts and holds the workpiece. The chuck table 2 is formed in a disc shape,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com