Preparation method and application of a photothermal thermoelectric catalyst based on thermoelectric materials

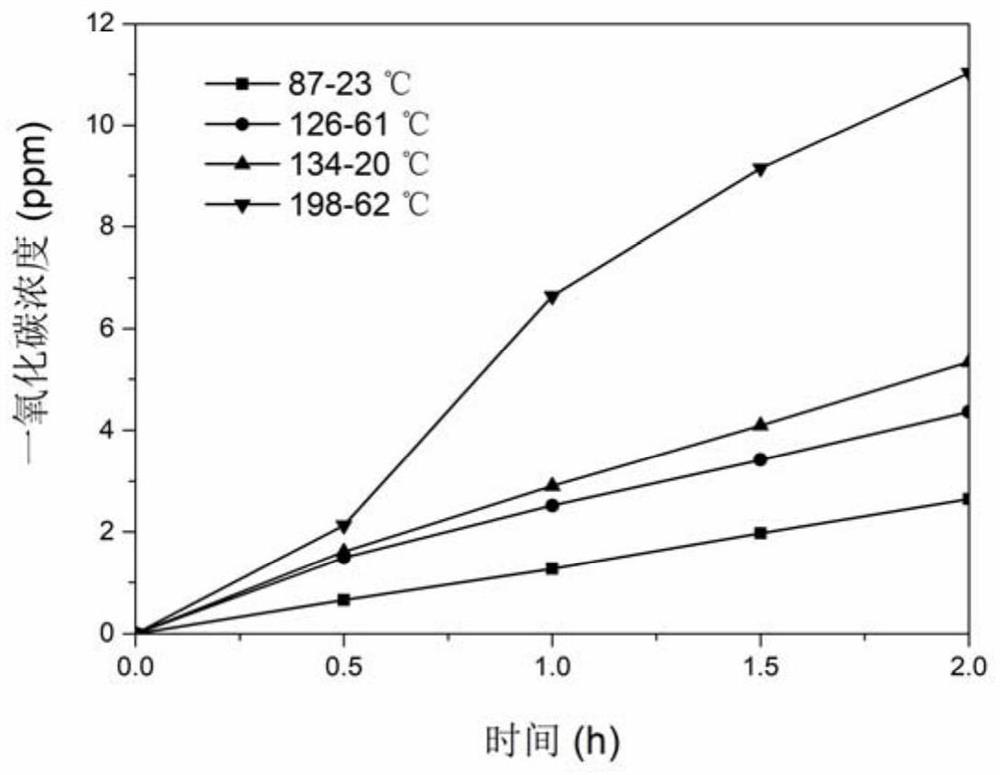

A technology of thermoelectric materials and catalysts, applied in chemical instruments and methods, physical/chemical process catalysts, carbon monoxide, etc., can solve the problems of low efficiency, high energy consumption, unfavorable preservation and transportation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the photothermal thermoelectric catalyst based on the thermoelectric material proposed by the present invention comprises the following steps:

[0027] (1) Preparation of bismuth copper selenoxy thermoelectric ceramic powder by solid phase method or mechanical alloying method:

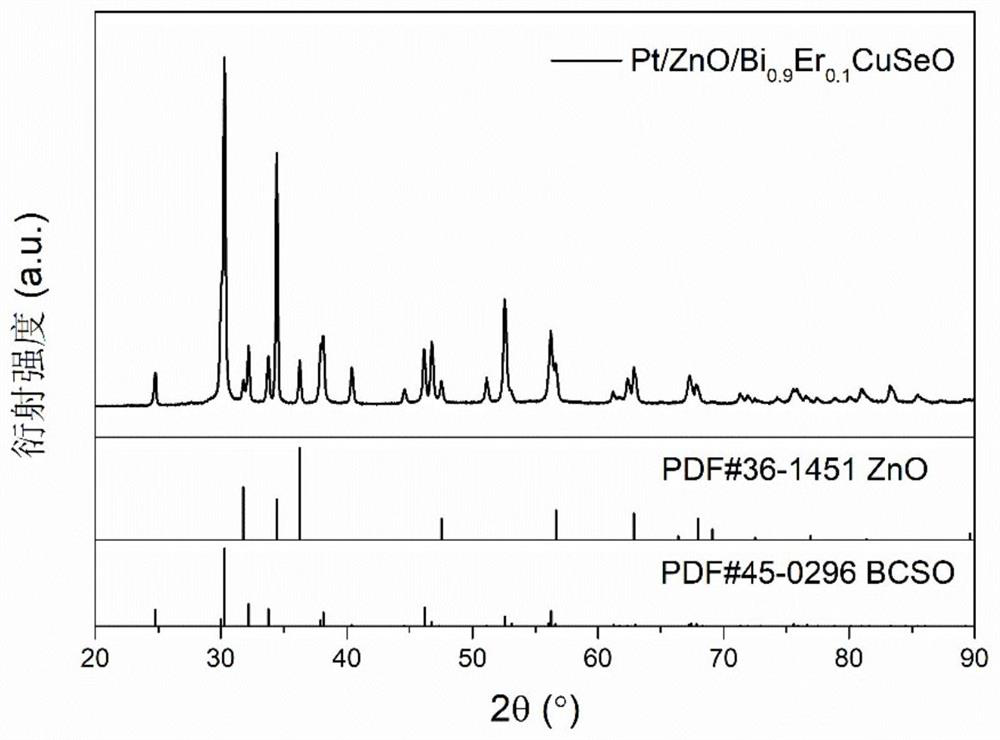

[0028] Bi in stoichiometric ratio 1-X Er X CuSeO, take by weighing the solid powders of bismuth powder, bismuth oxide powder, selenium powder, erbium oxide and copper powder, put all the raw materials into a ball milling jar or a mortar and mix well, then carry out high-energy ball milling under argon protection, and the ball milling time is For 8 hours, the speed of the ball mill is 400 r / min, and the erbium-doped bismuth copper selenoxy thermoelectric ceramic bulk powder is obtained, X=0~0.12;

[0029] (2) After crushing the ceramic powder in step (1), continue wet ball milling for 1 hour. After drying, the spark plasma sintering method is used. Under the pressure o...

Embodiment 1

[0048] (1) Preparation of bismuth copper selenoxy thermoelectric ceramic powder by solid phase method or mechanical alloying method:

[0049] For the bismuth copper selenoxy thermoelectric ceramics, the raw materials are bismuth powder, bismuth oxide powder, selenium powder and copper powder, and erbium oxide is selected as one of the raw materials for erbium element doping.

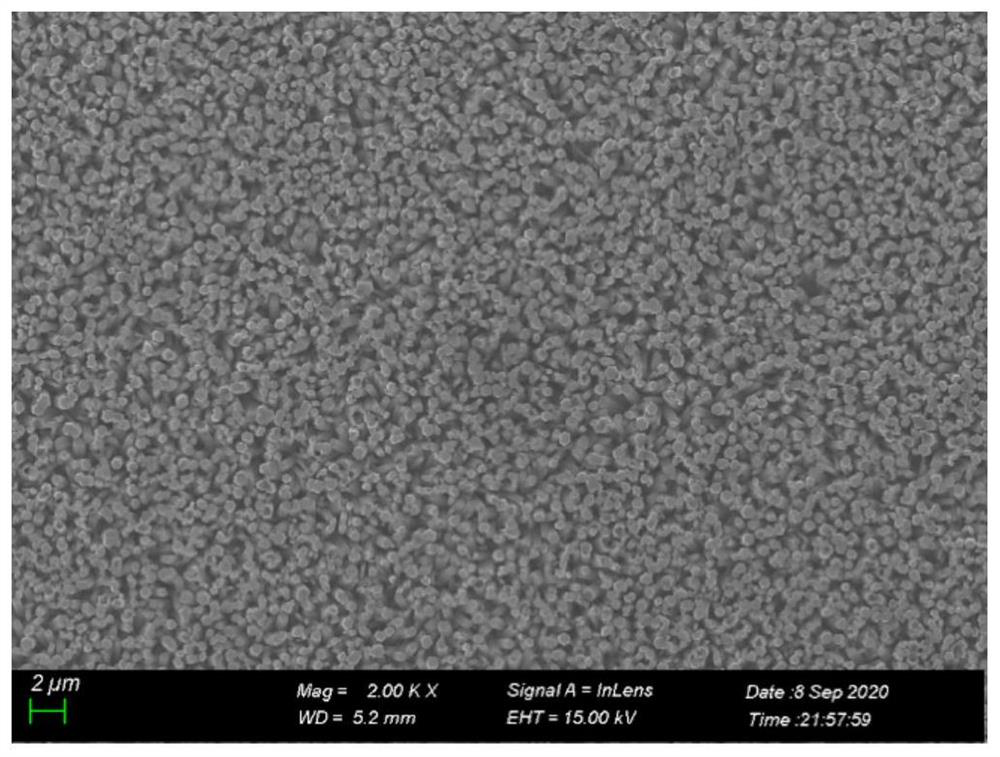

[0050] Bi in stoichiometric ratio 1-X Er X CuSeO, weigh the solid powders of bismuth powder, bismuth oxide powder, selenium powder, erbium oxide and copper, put all the raw materials into a ball milling jar or mortar and mix well, carry out high-energy ball milling under argon protection, and the ball milling time is 8 hour, the ball mill speed was 400 r / min, and erbium-doped bismuth copper selenoxide (Bi 0.9 Er 0.1 CuSeO) thermoelectric ceramic bulk powder, wherein X=0.1;

[0051] (2) After crushing the ceramic powder in step (1), continue wet ball milling for 1 hour, and after drying, adopt the spa...

Embodiment 2

[0059] (1) Preparation of bismuth copper selenoxy thermoelectric ceramic powder by solid phase method or mechanical alloying method:

[0060] For the bismuth copper selenoxy thermoelectric ceramics, the selected raw materials are bismuth powder, bismuth oxide powder, selenium powder and copper powder.

[0061] According to the stoichiometric ratio of BiCuSeO, weigh the solid powders of bismuth powder, bismuth oxide powder, selenium powder and copper powder, put all the raw materials into a ball milling jar or mortar and mix well, then carry out high-energy ball milling under argon protection, and the ball milling time is long For 8 hours, the speed of the ball mill was 400 r / min, and the bismuth copper selenide oxide (BiCuSeO) thermoelectric ceramic bulk powder was obtained;

[0062] (2) After crushing the ceramic powder in step (1), continue wet ball milling for 1 hour, and then adopt the spark plasma sintering method to keep the temperature at 650°C for 5min under the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com