Non-stick coating and method for production thereof

A technology of non-stick coating and covering layer, applied in the direction of coating, special materials for cooking utensils, etc., can solve the problems affecting non-stick performance, etc., and achieve the effect of good wear resistance, good non-stick effect and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

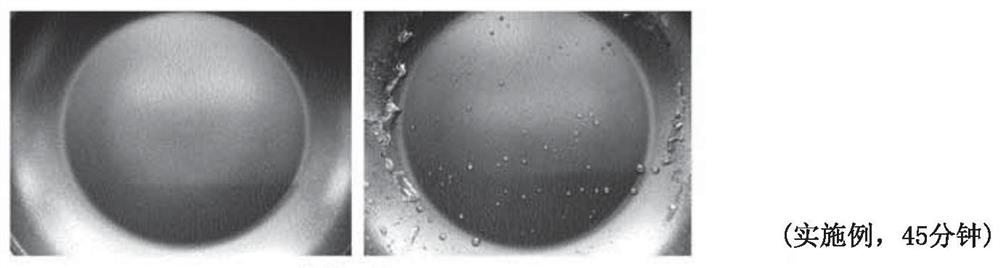

Image

Examples

Embodiment

[0045] A non-stick coating was examined which consisted of a cover layer with a dry film thickness of 35 to 40 μm and a base layer with a dry film thickness of approximately 15 μm. The cover layer in this example comprises about 99.3% by weight PTFE based on the total solids content of the cover layer, of which about 5.5% by weight is a polymeric modified PTFE comprising less than 1% by weight Perfluoropropyl vinyl ether (PPVE) was used as a modifying comonomer and obtained by emulsion polymerization, and had an average particle size of about 200 nm. In addition, about 0.4% by weight of effect pigments (mica), based on the total solids content of the cover layer, and about 0.2% by weight of carbon black pigments are included.

[0046] The adhesion promoter layer in this example consists of about 32.5% by weight alumina, 18.4% by weight polyamideimide, 13.7% by weight silicon carbide, 27.1% by weight PTFE based on the total solids content of the adhesion promoter layer , 5.5% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com