Water-based coating material of lithium battery diaphragm, preparation method and lithium battery

A lithium battery separator, water-based coating technology, applied in secondary batteries, battery pack parts, circuits, etc., can solve the problem of reducing the gas permeability of the separator and the migration number of lithium ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

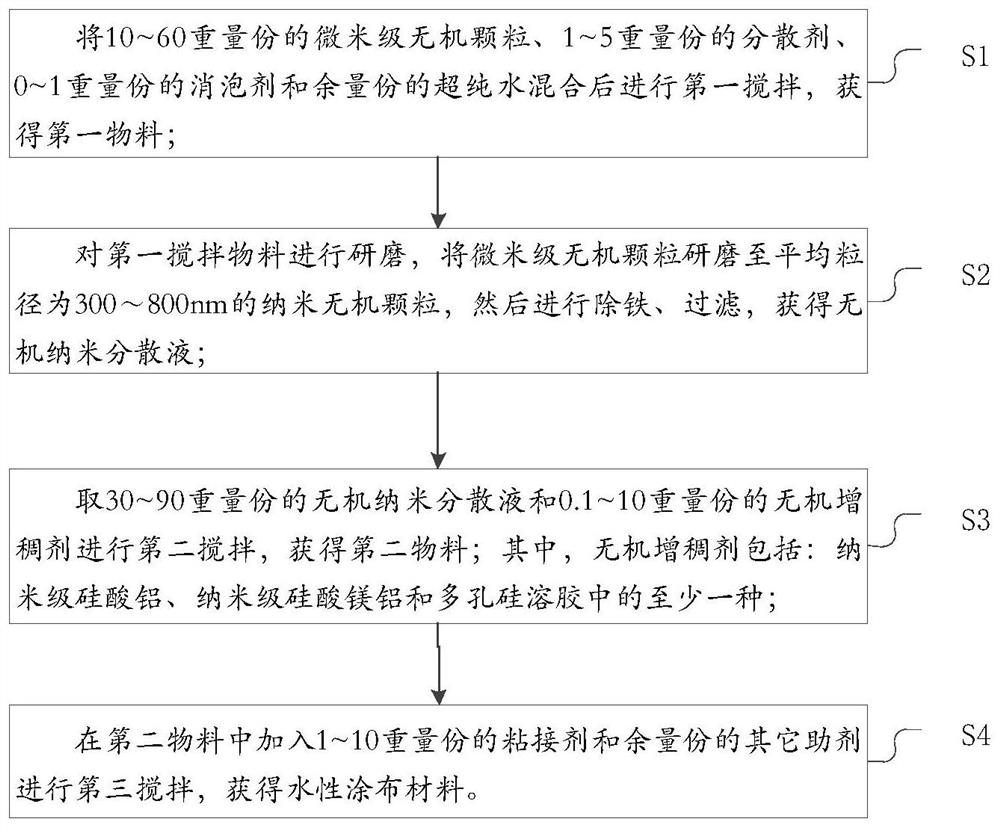

[0036] Such as figure 2 As shown, this embodiment also provides a method for preparing a water-based coating material for a lithium battery separator, which is used to prepare the above-mentioned water-based coating material. The preparation method includes:

[0037] S1: Mix 10 to 60 parts by weight of micron-sized inorganic particles, 1 to 5 parts by weight of a dispersant, 0 to 1 part by weight of an antifoaming agent, and the balance of ultrapure water, and then perform the first stirring to obtain the first materials;

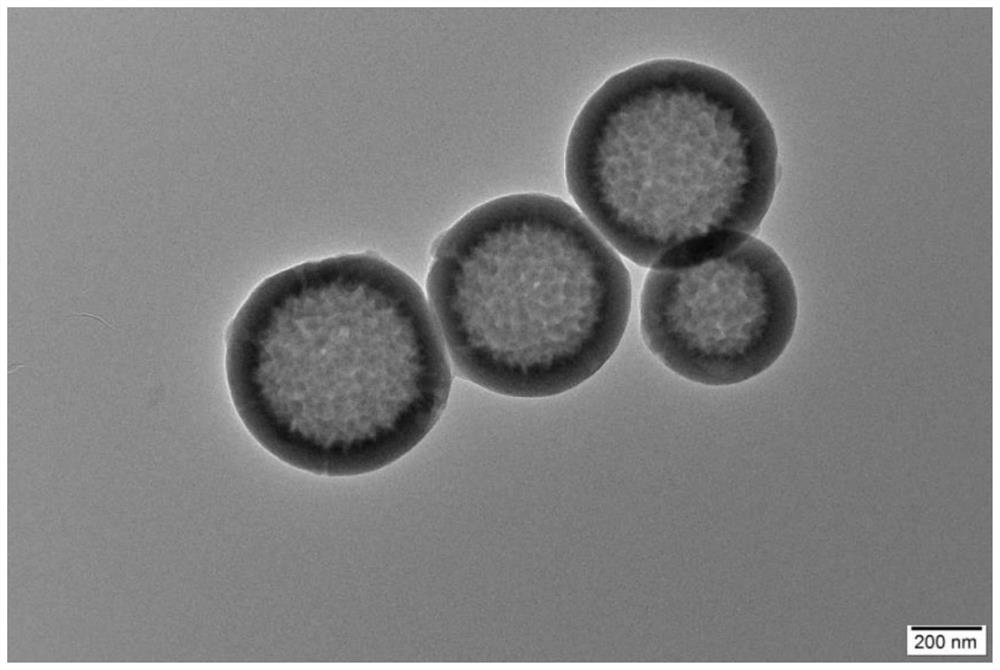

[0038] S2: Grinding the first stirring material, grinding the micron-sized inorganic particles to nano-inorganic particles with an average particle size of 300-800nm, and then removing iron and filtering to obtain an inorganic nano-dispersion;

[0039] S3: Take 30-90 parts by weight of inorganic nano-dispersion liquid and 0.1-10 parts by weight of inorganic thickener for the second stirring to obtain the second material; wherein, the inorganic thickener i...

Embodiment 1

[0051] Pour 47 parts of ultrapure water, 48 parts of alumina, 4 parts of sodium polyacrylate, and 1 part of polyoxypropylene glyceryl ether into the mixing tank in sequence, control the stirring speed at 120r / min, and pump the materials to the sand mill after stirring for 2 hours Grind for 8 minutes, during which the rotational speed of the grinder is controlled to be 1300r / min. After iron removal / filtration, an aluminum oxide nano-dispersion with an average particle size of 620nm and a hollow interior is obtained; then take 80 parts of the aluminum oxide nano-dispersion and control the pump speed at 130r / Add 5 parts of porous silica sol dropwise to the alumina nano-dispersion liquid at a stirring speed of 280r / min; then add 6 parts of polymethyl acrylate and 9 parts of other additives at a constant speed, and stir for 4 hours to obtain a lithium battery diaphragm water-based coating material .

[0052] Coat the above-mentioned coating slurry on the surface of the 9-micron PE...

Embodiment 2

[0054] Pour 51 parts of ultrapure water, 43 parts of silicon oxide, 5 parts of polyethylene glycol and 1 part of n-octanol into the mixing tank in sequence, control the stirring speed at 130r / min, and pump the materials to the sand mill for 10 minutes after stirring for 2 hours During the period, the rotating speed of the grinding machine is controlled to be 1250r / min, and the average particle size is 580nm and the hollow silicon oxide nano-dispersion is obtained after iron removal / filtration; Add 4 parts of nano-aluminum silicate dropwise to the silicon oxide nano-dispersion liquid at a stirring speed of 290r / min; then add 8 parts of polyethylacrylate and 3 parts of other additives at a constant speed, and stir for 4 hours to obtain a lithium battery separator water-based coating material.

[0055] Coat the above-mentioned coating slurry on the surface of the 9-micron PE base film by scrape coating and then dry it to obtain a single-sided coated PE diaphragm with a nano-inorga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com