Preparation method of NiCo2O4@Ni-Co LDH composite electrode for all-solid-state flexible supercapacitor

A technology for supercapacitors and composite electrodes, applied in the field of capacitors, can solve the problems of complex preparation, poor mechanical properties and stability of supercapacitor electrode materials, and insufficient chemical properties, and achieves simple preparation methods, good ion diffusion capacity, and good charge storage. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

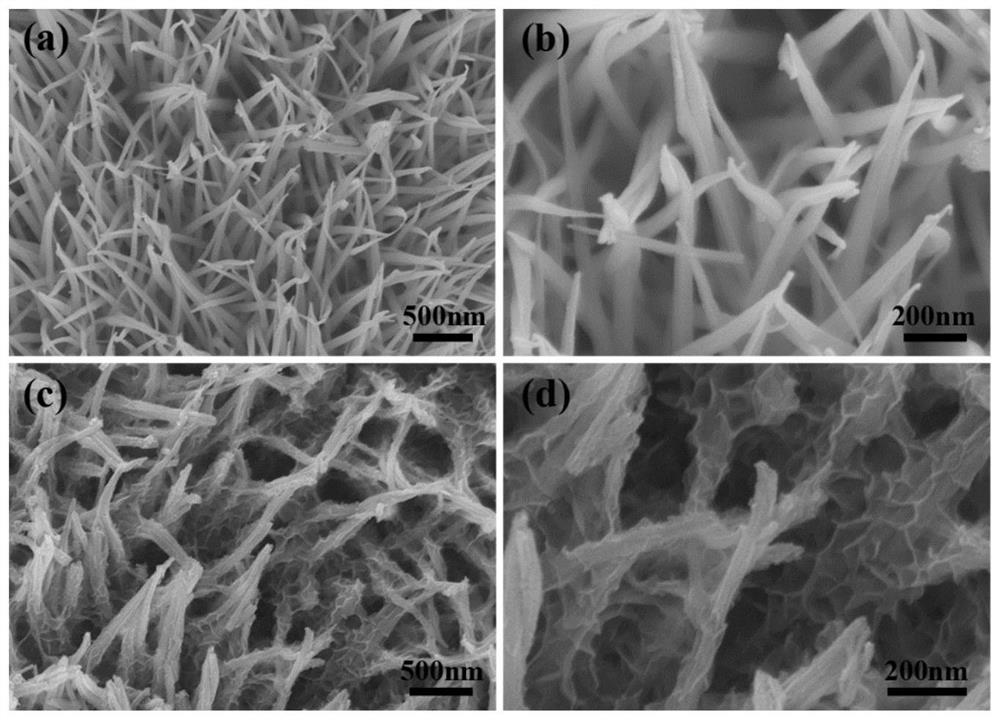

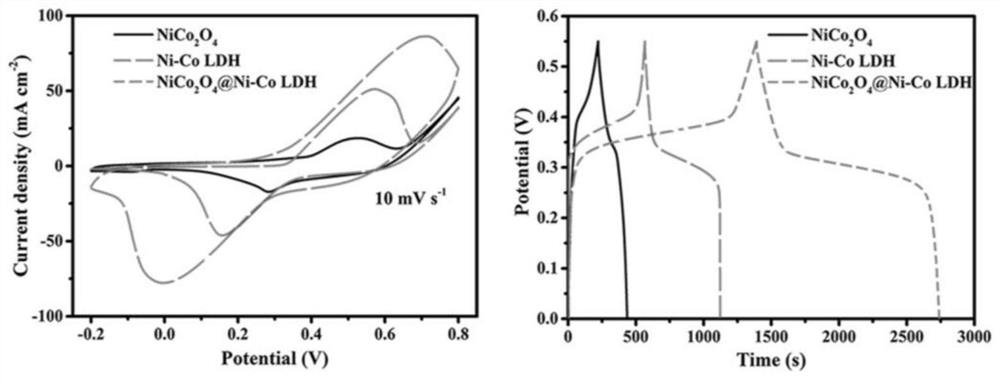

[0021] (1) 2mmol NiCl2·6H2O, 4mmol CoCl2·6H2O, 10mmol urea and 40ml deionized water were mixed and stirred to obtain a solution, and 0.1g NH4F was added therein, and stirred evenly to obtain a uniform solution.

[0022] (2) Put the carbon cloth into the solution vertically, and then put it into a vacuum blast drying oven at 120°C for 6 hours. If the time is too short, the active substances that grow up are too few; if the time is too long, the active substances that grow up are too dense leading to reunion.

[0023] (3) After taking out the carbon cloth, wash it repeatedly with deionized water and absolute ethanol for more than three times, put it in a vacuum drying oven and dry it at 70°C for 12 hours, then place the dry carbon cloth in a quartz tube furnace Heating from room temperature to 350°C with a heating rate of 2°C min-1, followed by annealing for 2 hours to obtain NiCo2O4 material.

[0024] (4) Mix 3.6mmol Ni(NO3)2·6H2O, 0.9mmol Co(NO3)2·6H2O, 50ml deionized water a...

Embodiment 2

[0029] (1) 4mmol NiCl2·6H2O, 8mmol CoCl2·6H2O, 20mmol urea and 80ml deionized water were mixed and stirred to obtain a solution, and 0.2g NH4F was added therein, and stirred evenly to obtain a uniform solution.

[0030] (2) Put the carbon cloth into the solution vertically, and then put it into a vacuum blast drying oven at 120°C for 6 hours. If the time is too short, the active substances that grow up are too few; if the time is too long, the active substances that grow up are too dense leading to reunion.

[0031] (3) After taking out the carbon cloth, wash it repeatedly with deionized water and absolute ethanol for more than three times, put it in a vacuum drying oven and dry it at 70°C for 12 hours, then place the dry carbon cloth in a quartz tube furnace Heating from room temperature to 350°C with a heating rate of 2°C min-1, followed by annealing for 2 hours to obtain NiCo2O4 material.

[0032] (4) Mix 3.6mmol Ni(NO3)2·6H2O, 0.9mmol Co(NO3)2·6H2O, 50ml deionized water a...

Embodiment 3

[0037] (1) 2mmol NiCl2·6H2O, 4mmol CoCl2·6H2O, 10mmol urea and 40ml deionized water were mixed and stirred to obtain a solution, and 0.2g NH4F was added therein, and stirred evenly to obtain a uniform solution.

[0038] (2) Put the carbon cloth into the solution vertically, and then put it into a vacuum blast drying oven at 150°C for 5 hours. If the time is too short, the active substances that grow up are too few; if the time is too long, the active substances that grow up are too dense leading to reunion.

[0039] (3) After taking out the carbon cloth, wash it repeatedly with deionized water and absolute ethanol for more than three times, put it in a vacuum drying oven and dry it at 70°C for 12 hours, then place the dry carbon cloth in a quartz tube furnace Heating from room temperature to 350°C with a heating rate of 2°C min-1, followed by annealing for 2 hours to obtain NiCo2O4 material.

[0040](4) Mix 7.2mmol Ni(NO3)2·6H2O, 1.8mmol Co(NO3)2·6H2O, 100ml deionized water a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com