Method for preparing environment-friendly optical material by utilizing rare earth hyperaccumulation plants

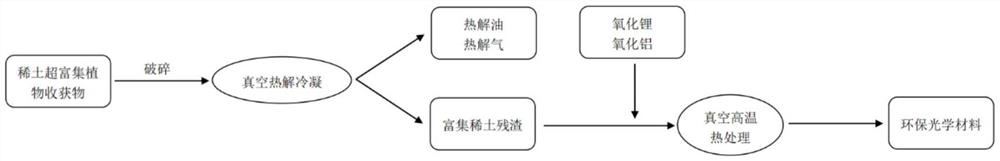

A technology for hyper-accumulation of plants and optical materials, which is applied in the field of preparation of environmentally friendly optical materials, can solve the problems of secondary pollution, waste of rare earth metals or heavy metal resources, etc., and achieves the effects of high recovery efficiency, beneficial to recycling and protection of the ecological environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

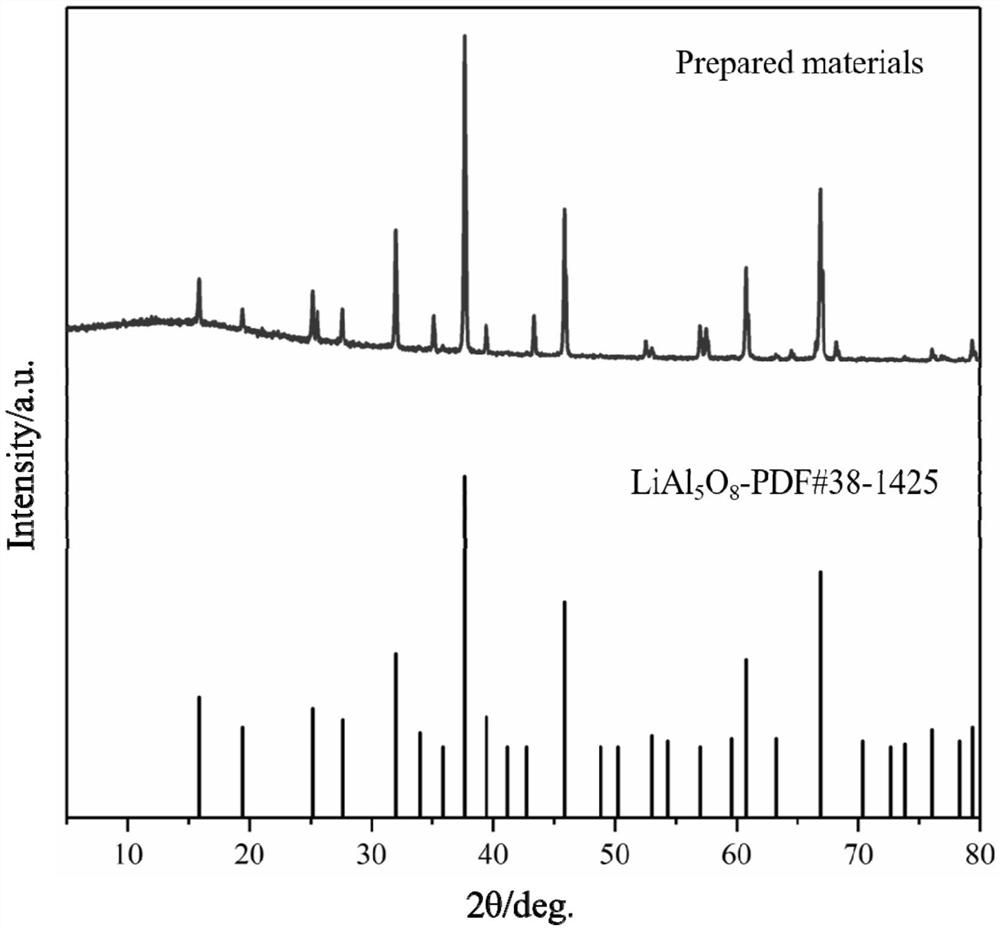

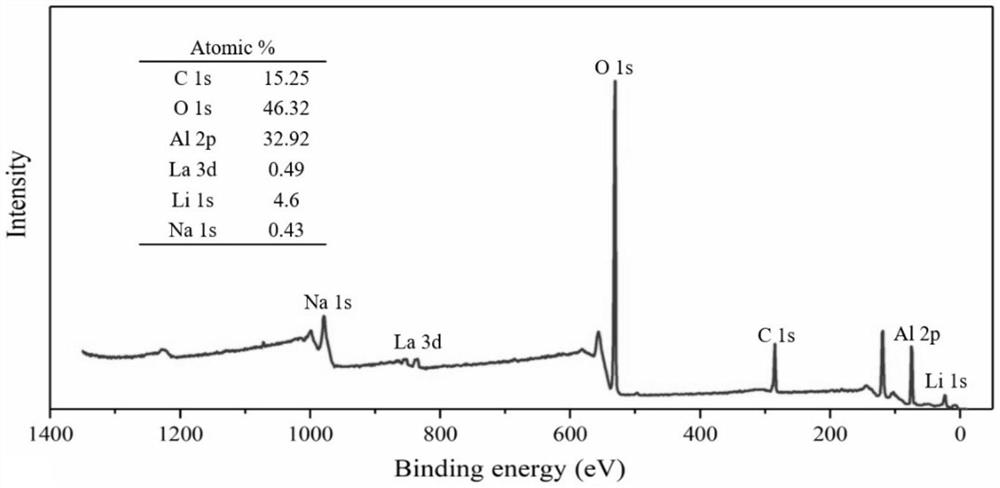

[0040] Example 1 A kind of recycling and preparation of environmentally friendly optical materials rare earth doped LiAl by using rare earth hyperaccumulation plant Osmanthus osmanthus 5 o 8 Methods

[0041] The method comprises the steps of:

[0042] S1. Drying the rare earth super-enriched Osmanthus plants, and placing the dried plants in a shearing crusher for crushing to obtain uniform Osmanthus powder; weighing 40g Osmanthus powder in vacuum pyrolysis and condensing in stages The device performs pyrolysis and condensation treatment: set the vacuum degree of the first section of pyrolysis area to 10Pa, the final temperature of pyrolysis to 700°C, the heating rate to 30°C / min, and the retention time to 30min; set the condensation temperature of the second section of condensation area to 180°C, the condensation temperature in the third condensation area is 80°C;

[0043]S2. After the pyrolysis is complete, a total of 27.666g of pyrolysis oil and pyrolysis gas are collecte...

Embodiment 2

[0049] Example 2 A rare-earth-doped LiAl prepared by recycling rare-earth hyperaccumulator plant pokeweed to prepare an environmentally friendly optical material 5 o 8 Methods

[0050] The method comprises the steps of:

[0051] S1. Dry the rare earth super-enriched pokeweed plants, and put the dried plants into a shear crusher to crush them to obtain uniform pokeweed powder; weigh 40g of pokeweed powder and perform vacuum pyrolysis Pyrolysis and condensation treatment of subsection condensation device: set the vacuum degree of the first section of pyrolysis area to 50Pa, the final temperature of pyrolysis to 600°C, the heating rate to 25°C / min, and the retention time to 30min; set the vacuum degree of the second section of condensation area to The condensation temperature is 160°C, and the condensation temperature in the third condensation area is 70°C;

[0052] S2. After the pyrolysis is complete, a total of 35.47g of pyrolysis oil and pyrolysis gas are collected. Using G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com