Core column bottling and packaging production device used in field of superhard material production

A technology of production equipment and superhard materials, applied in packaging, packaging machines, transportation and packaging, etc., can solve the problems affecting packaging efficiency, large space for push-pull rods, poor packaging effect, etc., so as to improve packaging effect and reduce occupied space. space, the effect of improving packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

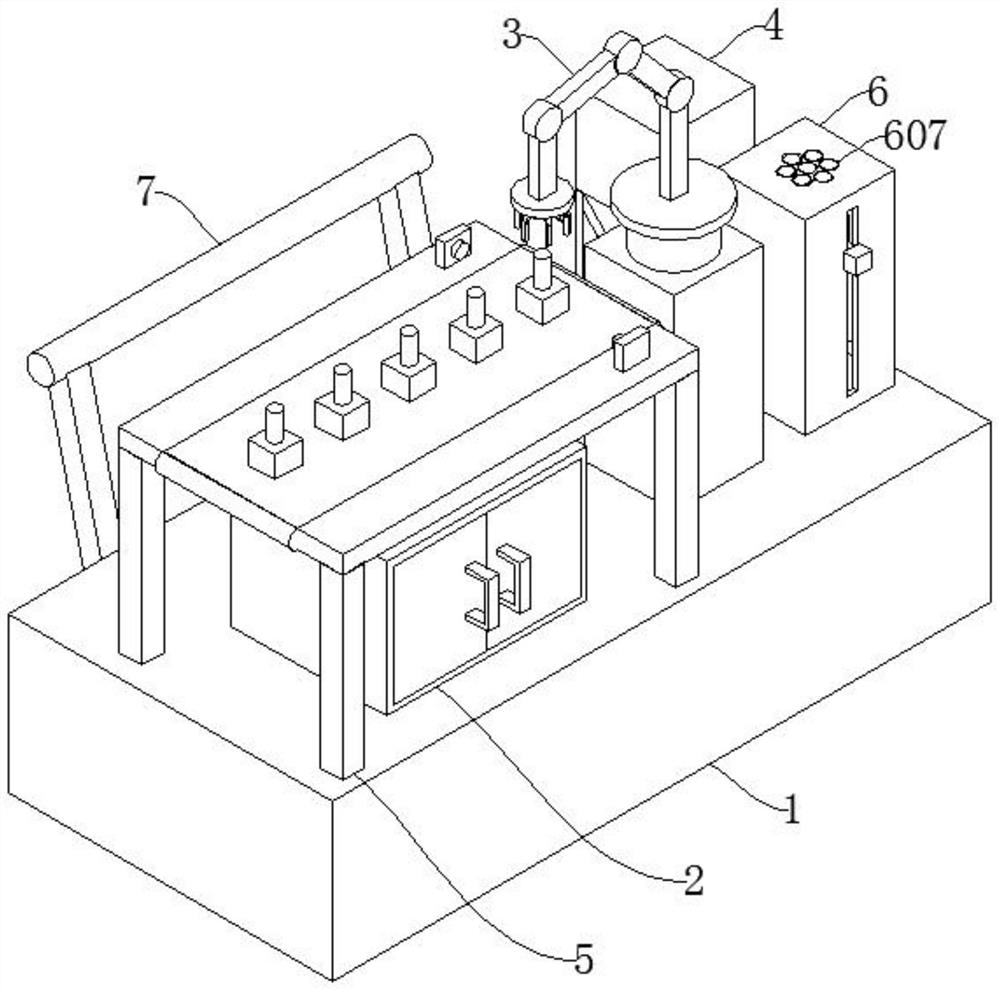

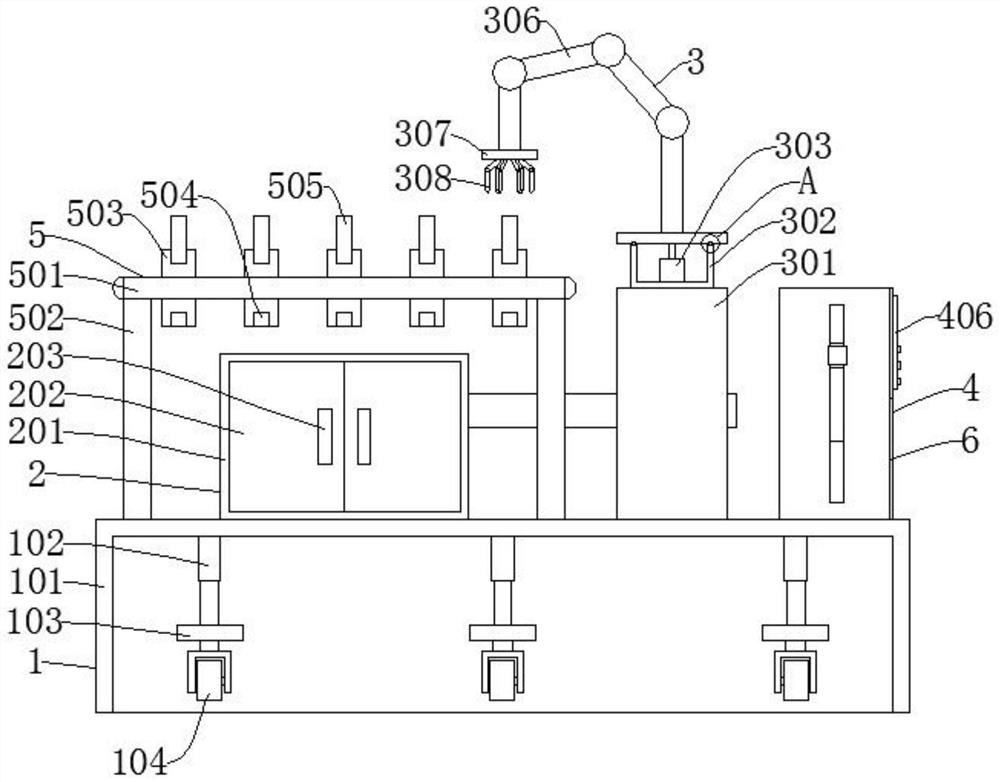

[0045] Such as figure 1 , image 3 , Figure 5 , Figure 7 , Figure 8 As shown, a stem bottling and packaging production device used in the field of superhard material production includes a support mechanism 1, a storage mechanism 2, a transfer mechanism 3, and a control mechanism 4. A storage mechanism 2 is installed above the support mechanism 1. One side of the storage mechanism 2 is provided with a transfer mechanism 3, a control mechanism 4 is fixed on the support mechanism 1, and a transportation mechanism 5, a packaging mechanism 6 for bottling the stem 505, a push-pull mechanism 7, and the transportation mechanism 5 is arranged on Above the storage mechanism 2, the packaging mechanism 6 is arranged on the side of the transfer mechanism 3 away from the transport mechanism 5, and the push-pull mechanism 7 is installed at the rear of the support mechanism 1;

[0046] The support mechanism 1 includes a base 101, a first electric push rod 102, a lifting plate 103, and ...

Embodiment 2

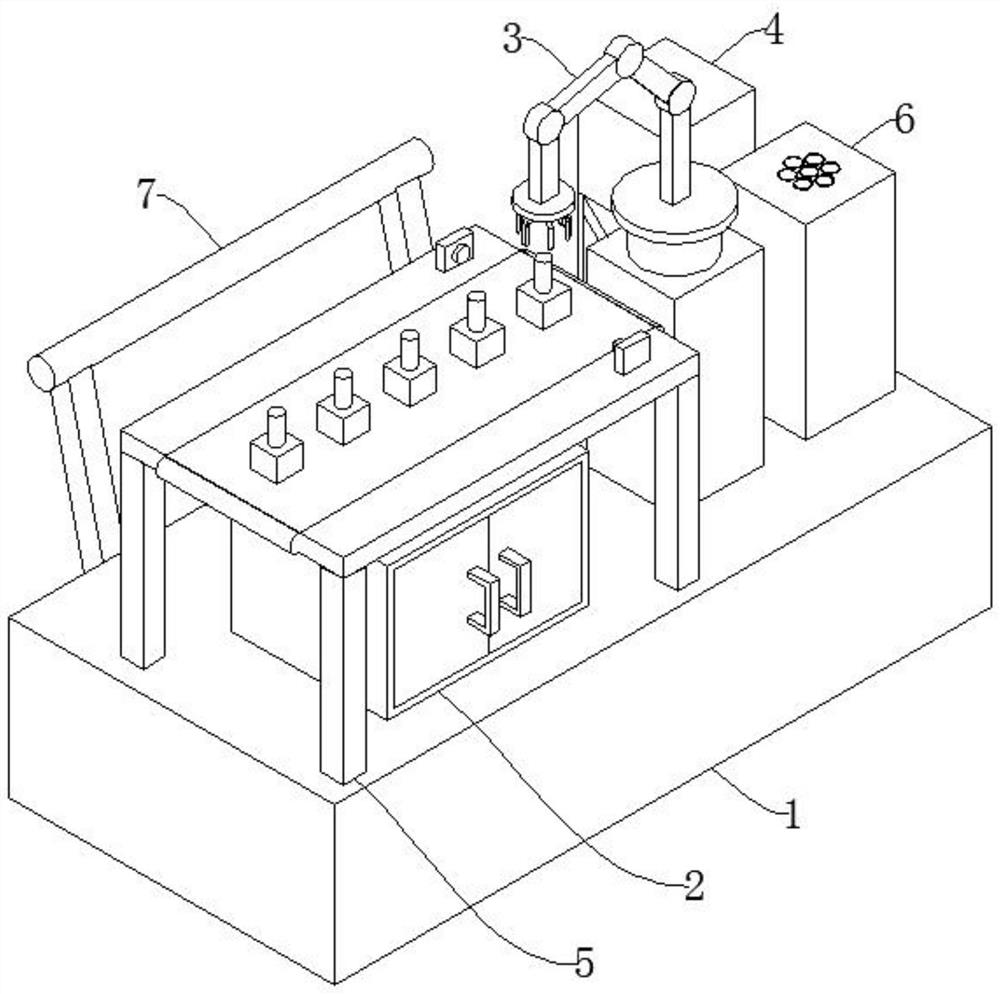

[0056] Such as figure 2 , Figure 4 , Figure 6 , Figure 7 , Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that the through hole 6041, the slide bar 6042, and the slide block 6043 are replaced with slide rails 6044 and slide seats 6045, and the load cell 605 detects that the weight in the packaging bottle 606 reaches the set value. When the value is fixed, the second electric push rod 602 shrinks and drives the placement seat 603 to descend, and the placement seat 603 drives the sliding seat 6045 to descend along the slide rail 6044, and the packaging bottle 606 also descends thereupon, and the stem column 505 in the feed pipe 607 is under gravity. Enter in the packing bottle 606 under action, finish feeding operation like this.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com